How to Design an Effective Racking System

Well-designed racking is an important part of any finishing operation. Richard Lang, who handles technical sales for EPSI’s racking and hanging division, offers insights for designing an effective racking system.

#asktheexpert #racking #basics

Q: What should I keep in mind when constructing a racking system?

A: A well-designed, well-made rack is not only an integral part of any finishing operation, it’s also an opportunity to save platers money through increased production capacity and reduction of rejects. While almost anyone can make a rack, an understanding of racking materials and their elements is imperative to produce a correct design. By learning a little about rack design, you can make better-informed decisions when dealing with suppliers and design the best racking system for your shop.

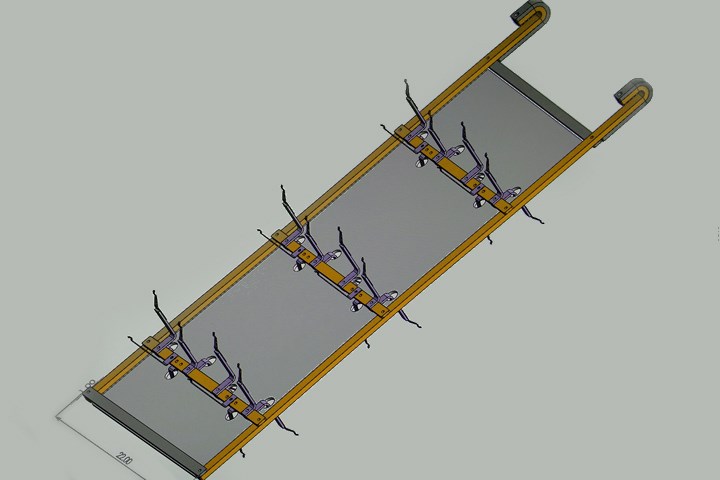

Solidworks rack design image. All photos courtesy of EPSI

Here are 5 considerations for designing your racking system:

- Make sure to communicate specific technical knowledge concerning your desired rack outcome.

- Without information about maximum practical amperages and current plating demands from you, a supplier cannot build a proper rack for your needs. These two factors are important for determining the size and materials used in framing a rack.

-

What material will you use for your rack? Copper is the most common framing material used in electroplating applications, but steel is increasingly being used in low current demand applications, such as zinc plating.

- Rack tip design and construction is key.

- I’ve seen people bend nails and weld them to a piece of rebar and call it a rack, but a true rack station requires much more thought. A good rack should hold the part in the correct position, be easy to rack and unrack, deliver proper current distribution and facilitate even plating thickness. The choice of tip material is very dependent on the end-user’s preference, but the most common material is 300 series stainless steel. These steels will nicely cover almost all plating tip or station applications.

Racking station tip.

- I’ve seen people bend nails and weld them to a piece of rebar and call it a rack, but a true rack station requires much more thought. A good rack should hold the part in the correct position, be easy to rack and unrack, deliver proper current distribution and facilitate even plating thickness. The choice of tip material is very dependent on the end-user’s preference, but the most common material is 300 series stainless steel. These steels will nicely cover almost all plating tip or station applications.

- What coating will you use?

- A coating must be applied to the completed rack to protect from

plating buildup and seal the soldered connections. In the past, wax and vulcanized rubber have been used. Today, plastisol, a polyvinyl chloride mixed in an alcohol-based plasticizer, is the most commonly used coating. It withstands the extreme environments of the plating process and adheres to the base metals with the aid of a lacquer-based primer. Adhesion of the coating is inversely proportional to the surface area exposed at the contact points and is very heat sensitive. It is important to remember that plating rack tips are made of the least efficient current-conducting materials and resistance produces heat that will destroy the bonding ability of the primer. This fact, along with the eventual leaching of the plasticizer, is what limits the useful life of the rack coating and leads to the deterioration of the rack itself.

Rack being dip-coated.

- A coating must be applied to the completed rack to protect from

- Other issues to keep in mind when dealing with suppliers and rack design include:

- Make sure the supplier is willing to produce a sample. Once it’s built, run it extensively through your line.

- Plan for business growth. Make sure your racks are designed to accommodate at least 25% to 40% more than your current demand.

- Don’t skimp or cut corners to save money. The old saying is true — you get what you pay for and you could end up spending even more later.

- Be as specific as possible in asking for what you want. No two shops are exactly alike, so you need to communicate your needs as clearly as possible when working with a racking supplier in order to get the right fit for your operation.

RELATED CONTENT

-

Top Reasons to Switch to a Better Cleaning Fluid

Venesia Hurtubise from MicroCare says switching to the new modern cleaning fluids will have a positive impact on your cleaning process.

-

Plating with Zinc-Nickel: Benefits and Challenges

Chad Murphy of Columbia Chemical speaks about the benefits of various types of zinc-nickel alloy, and provides tips for manufacturers about the zinc-nickel plating process.

-

Preventing Anodizing Cathodes from Turning Red

While the red color may not be desirable, anodizing expert Drew Nosti says it poses no particular problem to a successful anodizing process.