In-House Blackening of Ferrous and Non-Ferrous Metals

Process satisfies customers’ shipping requirements while meeting stricter water regulations in times of drought.

#basics #pollutioncontrol #regulation

In-house black oxide finishing continues to grow in popularity. There are many reasons why in-house blackening of iron and aluminum is more attractive than sending parts out to a plater, and they all come down to one simple concept: more control of quality, scheduling and costs.

Black oxide finished products include hand tools, cutting tools, gears, couplings, fasteners, and jaws.

All photos: Birchwood Technologies

Manual or automated, black oxide finishing systems are inexpensive to install as compared to painting, electroplating or anodizing systems. The latest CNC black oxide systems cost less than a small machining center and operate automatically, with low direct labor costs. Chemical costs are usually less than 20 cents per pound of finished parts and depend on work volume. These finishing installations can be modified so that rinse waters are purified and recycled, which allows manufacturers in drought stricken areas of the country to meet tough water consumption regulations.

Featured Content

Why Blacken?

- Black oxide adds value without altering dimensions or interfering with part assembly or operation. In addition, black oxide finishes are durable and offer long-term corrosion resistance in storage or service.

- In-house black oxide lines are supplied as pre-engineered systems, complete with operator training. They are easy to install and operate, and they can be adapted to accommodate any part size or volume.

- ISO and “Lean Manufacturing” programs are easier to administer when inventory stays in the plant.

- The main benefit of an in-house black oxide system is the ability to offer fast-track service for key shipments without raising inventory levels. Some report that they can receive a purchase order in the morning, machine and blacken the parts, then ship the same day or next day.

Corrosion resistance. A black oxide finish normally withstands up to 100 hours of neutral salt spray (ASTM B117) or several hundred hours of humidity (ASTM D1748), depending on the sealant used. Black oxide finishes do require a sealant of some type because the black finish itself has a porous crystal structure. Although the sealant is primarily responsible for the corrosion resistance, the underlying black coating acts as an absorbent base, holding the sealant in contact with the metal substrate.

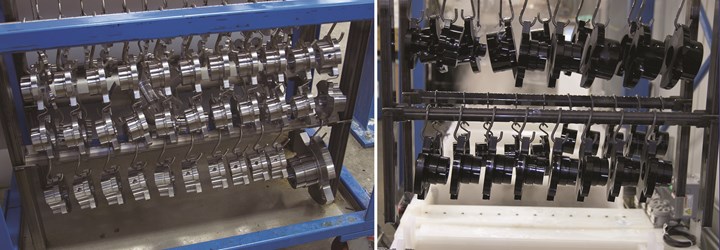

Left, unfinished couplings; right, finished couplings. The finish produced by low-temperature blackening is equivalent to hot oxide with a deep black uniform appearance and high corrosion protection.

Dimensional Uniformity and Stability. Black oxide finishes have a uniform thickness of about 0.000020 inches, making them ideal finishes for precision manufactured components that cannot tolerate the variable thickness of paint or electroplating.

Blackening Process Options

- Room Temperature Blackening. Utilizing copper/selenium chemistry, this system operates without heat and forms a black conversion coating in 2-5 minutes. These finishes can replace caustic black oxide in many applications, but the finish is not quite as durable. Because copper and selenium are both regulated by EPA, these process lines are often fitted with Ion Exchange to purify and recycle the rinse waters for zero discharge operation.

- Low Temperature Black Oxide for iron and steel. Using a patented chemistry, this system operates at 200°F and forms a durable, black magnetite finish that is Mil Spec compliant in 25 minutes. The basic chemistry is the same as that of high-temp black oxide, but the reaction proceeds at a lower temperature because it blackens in two steps. Since the process contains no EPA-regulated metals, the rinse waters are generally sewerable as non-hazardous discharge. Its low temperature eliminates the severe hazards of the 290°F black oxide, making it easier and far safer to operate. The process also avoids the red coatings and white salt leaching commonly seen with conventional black oxide because the overall concentration of caustic soda is 80 percent lower than that of regular black oxide.

- Low-Temperature Black Oxide for aluminum. Also utilizing a unique, patented chemistry, this system operates at 200°F and develops a smooth, durable black coating that is 0.000060 inches (1.5 micron) thick. Unlike anodizing, this new electroless process utilizes a simple dip-tank procedure to form the coating. The process takes just 30 minutes for most alloys and will not shrink hole diameters or add measurable thickness to part surfaces/dimensions. The process line is designed to operate as a self-contained, zero-discharge system. Rinse waters are purified and recycled by means of an ion-exchange system. This process provides a high-quality method for blackening aluminum that doesn’t involve the complexities and high costs of electrolytic black anodizing. The black finish offers excellent surface lubricity for break-in or galling resistance.

Near-Zero water recycler makes the finishing line a closed-loop process and reduces water consumption by 99 percent.

Ion Exchange and Near-Zero Water Recycling Systems. Most room temperature and low temperature steel blackening lines work very well by sending their rinse waters directly to the city drain, untreated, as non-hazardous discharge. With water restrictions put in place across the country, many manufacturers are looking for low water consumption finishing options. In these areas, blackening installations can be configured so that the rinse waters are not sent to the drain, but rather are purified and recycled, by means of an Ion Exchange or a Near-Zero Water Recycling System. Though the Ion Exchange or Near-Zero System raises the initial capital cost of the installation, it lowers the operating cost by making the process line completely self-contained, eliminating the need for a discharge permit, the accompanying sewer sampling program, and decreasing water consumption by 95 percent.

These processes work well on an in-house basis, and are easy, safe and economical to operate. The system supplier offers expert guidance on which process is best for each application and can also size and design the process lines and provide operator training.

Process design. Though many installations operate with a standard process sequence, the design of the process line can change to accommodate different production conditions:

- The size and volume of parts per shift will determine the overall size of the blackening tanks.

- The method of parts handling required (racks, baskets, rotating barrels) affects the way in which the parts are processed through the line.

- The condition of the surface prior to blackening may call for special cleaning or descaling provisions. Parts that carry heavy oils or oxides (rust, heat treat scale or hot-rolled mill scale) often require aggressive cleaning or descaling treatment utilizing chemical or grit-blasting methods.

- The performance requirements of the final finish will indicate which sealant is needed to achieve the necessary appearance, gloss and level of corrosion resistance.

A well-designed tank layout can accommodate all the factors listed above, and the supplier of the system can offer guidance in these areas. Most standard process lines contain the following stations: (1) cleaning, (2) rinsing, (3) surface conditioning, (4) rinsing, (5) blackening, (6) rinsing, (7) sealing.

Areas of Opportunity for Manufacturers

Lean Manufacturing. To paraphrase one company’s motto: Zero defects, zero waste, zero incidents. This goal equates to maximum customer satisfaction at minimum cost, and is achieved by streamlining part movement and controlling each phase of the entire manufacturing process. In-House black oxide can play a key role in this program.

Controlling Quality & Costs. Sending parts to an outside plater for black oxide requires part sorting and packing, freight costs, 2-5 day turnaround, and then paying the finisher a profit to do the work. This practice requires higher inventory levels, complicates ISO controls and makes it more difficult to offer customers quick response.

With an in-house process, either manual or CNC black oxide system, turnaround times are less than an hour. This lowers costs and inventories, streamlines workflow patterns, enhances ISO accountability and provides better control over finished part quality.

Enhancing Part Value. Sending parts outside for finishing is a costly and avoidable production bottleneck. While finishing contributes only a small portion of the part’s total value, the cost of sending work outside is often inordinately high when all the hidden factors are considered.

Satisfying the Customer. Prompt shipments of high-quality products help win new orders. In-house finishing helps to reduce costs and inventory while keeping the customer satisfied.

The Added Benefit of Security. Some manufacturers are not able to send parts outside for finishing due to security reasons. In-house blackening systems solve this problem when manufacturing parts with serial numbers, proprietary designs, and confidential part counts. In-house blackening systems are the ideal finishing choice for product assemblies with sliding contacts including firearm mechanisms, munitions and military assemblies.

Whether manual or automated, standard or electroless, black oxide finishing has proven integral to modern manufacturing because it enhances objectives while lowering costs.

RELATED CONTENT

-

Pretreatment of Black Oxide

Having issues achieving a consistent color with the application of black oxide? Start by looking at your pretreatment. Connor Callais of Hubbard-Hall offers advice for troubleshooting your black oxide process.

-

Plating Additively Manufactured Plastic Parts

Using electroplating to enhance the structural properties of 3D printed parts.

-

Tin-Zinc Alloy Electroplating and Its Corrosion Behavior

An NASF/AESF Foundation Research Program Retrospective