Infrared Curing: Evaluating the characteristics of IR energy

Infrared (IR) energy can be used as a source of heat to cure a variety of industrial coatings. Such infrared curing applies energy to the coated part surface by direct transmission from an IR emitter, which can provide source temperatures of anywhere from 500 to 4,200°F

#energy #curing

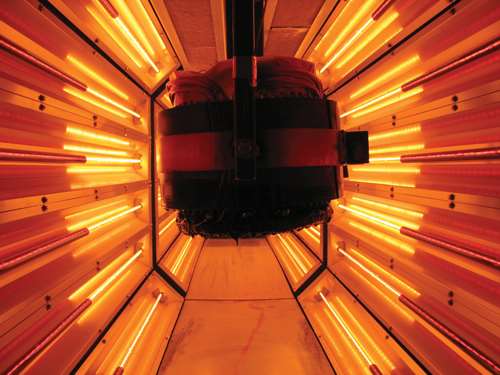

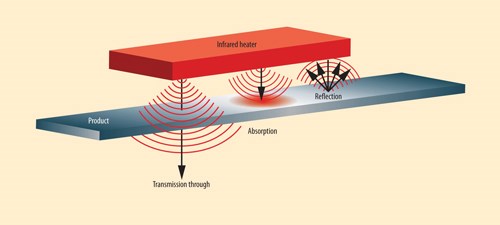

Infrared (IR) energy can be used as a source of heat to cure a variety of industrial coatings. Such infrared curing applies energy to the coated part surface by direct transmission from an IR emitter, which can provide source temperatures of anywhere from 500 to 4,200°F (Figure 7-2 – IRED 2010). Some of the energy is reflected off the surface, some is absorbed into the coating, and some heats the substrate. In powder coating, this direct transfer of energy creates an immediate reaction in the polymer, and curing (called crosslinking) begins quickly once the surface is exposed to the emitter. For paints and other coatings, infrared energy enables drying (Figure 7-1 – IRED 2010).

In IR curing ovens, heat is very rapidly transferred by radiation directly to the coating. Infrared ovens can cure a coating much faster than convection ovens, since they directly heat the part surface that is coated and do not waste BTUs to heat the entire substrate or the surrounding air. Subsequent heat conduction may sometimes cure even areas of the part that are not completely exposed to direct IR heat; however, differences in part structure and mass will affect the uniformity of this cure unless the intensity of the infrared heat is adjusted for these differences.

Featured Content

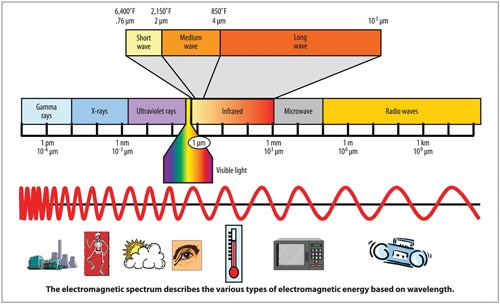

Infrared light is located on the electromagnetic spectrum between visible light and microwaves, and is measured in microns. Temperature determines the wavelength of the source IR emitter, so its peak wavelength can be controlled by changing its temperature. However, although all emitters can be adjusted for wavelength in this way, not all heaters are designed to emit the complete spectrum of long, medium and short wavelengths.

Influence of Coating Characteristics

The rate of IR absorption, reflection or transmission by a coating depends on the coating’s spectral characteristics, which include its emissivity and color, as well as other surface characteristics. Emissivity is a measure of the material’s efficiency in emitting radiant energy and is defined as the fraction of energy being emitted relative to that emitted by a thermally black surface (blackbody). It is measured on a scale of 0 to 1, with an ideal blackbody having an emissivity of 1. Emissivity and absorptivity are closely related, so materials with a high emissivity value also readily absorb radiant energy. Highly reflective surfaces (e.g., polished metals) would have low emissivity/low absorptivity and would be difficult to heat with IR.

Another important spectral characteristic that plays a role in the ability of the coating to absorb or reflect IR energy is color sensitivity. This is of particular concern with highly reflective colors such as chrome or silver. Color sensitivity is more pronounced with short-wavelength IR that is produced by higher-temperature emitters. For this reason, shortwave emitters are the most color sensitive while long wavelength emitters are the least color sensitive.

Testing of various wavelengths and temperatures to determine the most efficient emitters for IR curing is offered free by most IR equipment manufacturers. Generated time/temperature curves assist in the selection, size and orientation of the emitters to the part, and can help determine the overall design of the appropriate IR oven for a particular application.

Curing with Infrared

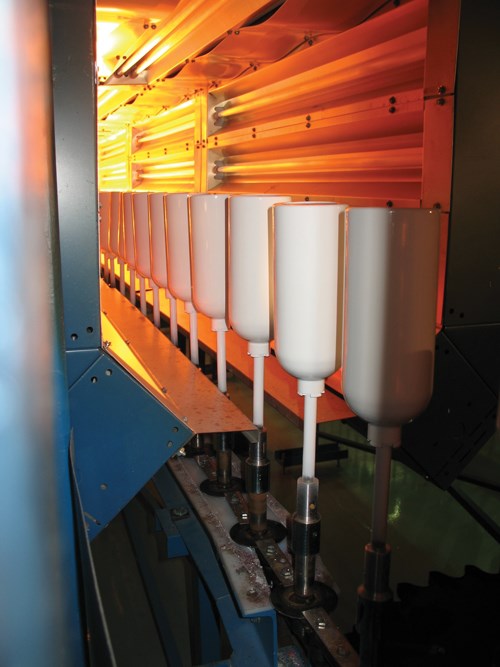

As previously mentioned, infrared ovens can quickly cure coated surfaces that are directly exposed to the IR heat, but areas that are not completely exposed may not cure uniformly unless the IR intensity is adjusted in those areas. There are several methods commonly employed in IR oven design to overcome cure variations and maintain precision. One such method is the use of a variable controller such as a silicon-controlled rectifier (SCR) that will modulate the intensity of the individual IR emitters. A second method would be to precisely “zone” the IR banks within the oven to apply heat (and proper intensity) to the various areas of the part based on requirements of high, low or no energy. Finally, IR can be focused through the use of reflectors and baffles to achieve the correct amount of intensity and coverage at different areas.

Areas of a part that are obscured from the IR emitter by their geometry will rise in temperature at the same pace as areas that are directly exposed to the emitter, while any unexposed areas may not even cure with conduction. In these cases, IR heat alone may not be the best option for the final coating cure. However, it can be useful to accelerate the cure cycle when used in conjunction with convection heat.

Using Dual Technologies

Ovens that use IR in addition to convection heat can provide benefits of both technologies, especially for complex parts with areas that are not directly exposed to the IR heat, or that vary significantly in mass or thickness.

When the part is heavy and consistent in shape, IR emitters offer the best cure method. Emitters can be arranged in a pattern that can raise the surface temperature much faster than convection and cure in much less time. IR may be the only practical way to cure certain types of parts while providing a much shorter curing cycle time.

A radiant preheat zone or “booster zone” at the entrance of a convection cure oven can be an excellent enhancement, especially for thick and massive components. Curing will begin immediately and can be accomplished faster than convection heating alone.

Gas IR emitters can be very effective as well. Like electric emitters, they can be purchased in modular sections and can be zoned. The BTUs required to operate a gas-fired IR emitter will typically cost less than the kilowatt-hours required for electric IR emitters. Actual energy usage comparisons of gas verses electric can only be made by evaluating the efficiencies of the emitters with respect to the spectral characteristics of the coating and the specific factors affecting the parts.

In summary, despite some of its limitations in uniformly curing parts of more complex shapes, infrared heat can be a good, fast curing option for many applications.

Material has been provided with permission from the IHEA Infrared Equipment Division’s “Infrared Process Heating Handbook for Industrial Applications, Second Edition.”

Fostoria Process Equipment Div. of TPI Corp.

RELATED CONTENT

-

Using Alternatives in Pretreatment Baths for Degreasing

Effective cleaning at low, even ambient temperatures, is possible, says Atotech’s Brandon Lloyd, and creates a safer work environment and reduces energy demands.

-

Energy Coatings Withstand Time, Corrosion

The Z-Pex multi-layer system battles harsh oil and gas chemicals.

-

Firearms and Flatware Feed Silvex’s Growing Electroplating Operation

It’s obvious that Silvex specializes in silver, but its processes also reach into the defense, aerospace, power generation and medical industries.