Bleed and feed.

Photo Credit: Surface Technology Inc.

Innovation can take many forms. Sometimes it can mean simply building on an existing idea. In 2015, Surface Technology Inc. (STI, Ewing, N.J.) introduced its One-Plate electroless nickel (EN) system. The system built on the work by STI and other EN suppliers who sought to find replacements for lead and cadmium in response to increasingly tight End of Life Vehicle (ELV) and Restriction of Hazardous Substances (RoHS) regulations.

Inspired by this change in the industry, STI theorized that if the non-lead/cadmium stabilizers work in a wider range of effective concentration in the EN bath, then other ingredients could be selected and formulated to also work in a wider range with the goal of replacing the decades-old multiple component EN systems with a single component. STI’s resulting One-Plate EN single bath make-up and replenishment solution simplifies the EN process by combining the three solutions that historically comprised EN baths into one solution.

Featured Content

“One-Plate is one chemical, period,” says Michael Feldstein, president of STI. “Instead of the traditional three components A, B and C, One-Plate uses just one component we call Q. The plating shops make up the bath with Q and water and replenish with the same Q. That’s it. All the ingredients that are needed are in that one solution.”

Recognized as an innovation in 2016 by Products Finishing, the medium phosphorous One-Plate offers numerous benefits and process improvements. The solution streamlines the EN process, thereby improving consistency of quality and offers cost savings in the form of reduced shipping and simplified inventory procedures. Products Finishing also brought One-Plate to the attention of our readers in an October 2017 article on its use at a plating shop in Detroit (read the article here).

But STI hasn’t stopped there and One-Plate’s potential continues to be explored. One-Plate is now used in over 20 countries in low, medium, high phosphorous, and composites with Teflon, Diamond, Boron Nitride, Silicon Carbide and other versions. Recently the company has been working on a bleed and feed methodology that uses One-Plate to great effect. The concept was calculated on paper, tested in the laboratory, and is now validated through use in a leading plating shop.

The quest for constant improvement

Based in Orskany, N.Y., Square One Coating Systems boasts over 100 years of combined metal finishing experience and is staffed with some of the leading experts in the U.S. in the field of electroless nickel technology. The company offers a wide range of EN solutions from low phosphorus to high phosphorus to polytetrafluoroethylene (PTFE) to diamond co-deposit.

According to Lloyd Ploof, president of Square One, the company is largely focused on higher-value work, serving many applications in the aerospace and military sector. The company is AS9100 and NADCAP certified. Square One’s facility is currently approximately 14,000 square feet and the company is working to double that in the spring. Ploof says the expansion is driven by increasing demand as well as increasing capabilities.

“We’ve diversified our processes over the last couple of years,” says Jody McRedmond, operations manager, citing precious metals, zinc and anodizing capabilities.

“We continually push for quality improvements here,” Ploof says.

Square One is no stranger to STI. The company had already validated the One-Plate medium and high phosphorous and nickel Teflon products were not ‘too good to be true’ and worked well in their shop; producing high quality coatings in a simplified way with no drawbacks. When Feldstein suggested a bleed and feed approach for the company’s mid-phos EN on aluminum, Ploof was more than willing to give it a try.

Bleed and feed

Typically, EN baths are made-up, replenished, used, replenished and so on until the bath reaches the end of its useful life. This is measured in Metal Turn Overs, or MTOs. When plating on steel and stainless steel, Square One runs the One-Plate baths to 10-12 MTO before making up a new bath. When plating on aluminum, the buildup of the zincate material from the pretreatment process into the bath reduces the MTO limit to about 5-6 before adhesion issues can arise. Extending the life of the EN bath for aluminum is a goal long desired in the industry.

The bleed and feed approach turns out to be a very workable way to achieve that goal when plating on aluminum. The process involves periodically removing (bleeding) a portion of the bath and replacing (feeding) with fresh solution.

Feldstein says bleed and feed is “a technology mentioned in the textbooks written by the pioneers of electroless nickel, but not practiced in the industry due to lack of practicality.” The multiple chemical solutions traditionally used for EN systems basically meant starting over with a new bath was easier than bleed and feed. It still may be when plating in steel. However, a single component system changes the whole ball game when plating on aluminum.

The bleed and feed method using One-Plate takes advantage of the low cost to make up a new bath with a single component. Feldstein explains that the One-Plate bath is made with just 15% by volume of the single Q component instead of 20-22% of the A and B components used in traditional EN systems = ~30% less materials and cost. The benefits of bleed and feed include:

- Less materials used

- Less bath waste

- Consistent bath operation (temperature, pH, maximum plating rate, stability)

- Consistent plating quality (appearance, brightness, corrosion resistance, adhesion, stress)

The use of a single component EN system like One-Plate makes the once impractical bleed and feed method not only practical, but potentially profitable for the plater and beneficial for the environment. Through the use of a single component EN solution and bleed and feed, plating shops can increase quality and consistency, reduce material usage, decrease costs and minimize unnecessary waste.

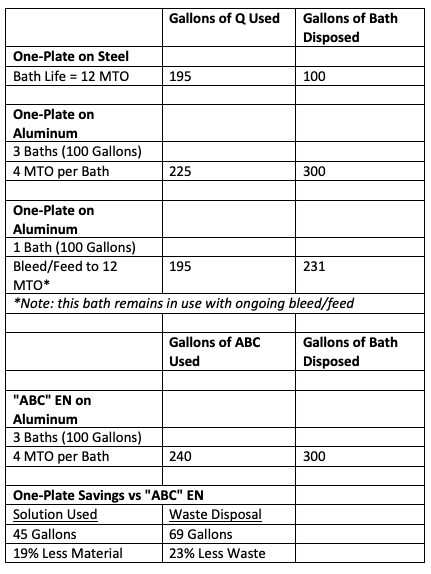

Chart 1: Comparison of material used and disposed with the bleed and feed vs traditional approach with an EN bath using three “ABC” components; shows 19% less solution used and 23% less waste.

Building upon innovation

Prior to using One-Plate and a bleed and feed approach, Square One was either 1) running an alkaline strike prior to the EN bath that required a two tank approach to extend the life of the EN bath, or 2) making up new EN baths after about 4 MTO to avoid adhesion issues and then continuing to use these baths for plating on steel. The new approach eliminated the alkaline strike bath. In addition, rework has gone down, quality has gone up and waste has been reduced.

“It really simplified the whole process,” Ploof says.

The brilliance of STI’s One-Plate is in its simplicity. Feldstein is quick to point out that it was created through looking to innovations that came before and a quest to further simplify EN processes. That work to continually improve and simplify led to the use of a simple-in-theory technique in bleed in feed. And while bleed and feed wasn’t a perfect idea in the past because of the complicated mix of chemicals that needed to be mixed for any replenishment of a bath, the simplification that a one component system offers proved to be the puzzle piece that needed to fit in place to make it a viable methodology. Within that recognition lies the innovation.

RELATED CONTENT

-

Troubleshooting for Electrocoating

Characterizing the type of defect is essential in identifying the root cause and eliminating its source...

-

8 Things You Need to Know About Paint Booth Lighting

Global Finishing Solutions has come up with some helpful insights on lighting for paints booths which plays a crucial role in achieving a quality paint job.

-

Coatings Drive Electric Vehicles Further

Electric vehicle batteries depend on coatings to maintain optimal temperatures, reduce the risk of fire damage and electrical interference, and more.