Innovative, Hybrid Functional Coatings for Aluminum and Titanium Substrates

This paper describes a low cost alternative coating technology for light metals that electrodeposits an engineered thin-film coating which bonds tightly to the substrate and provides excellent corrosion and wear resistance along with superior electrical and thermal performance. As a new process, this technology offers a stable, low-cost option to manufacturers and applicators seeking to improve and extend their use of light metal substrates.

#research #surfin

Editor’s Note: The following is a synopsis of a presentation given at NASF SUR/FIN 2018, in Cleveland, Ohio on June 4, 2018 in Session 5, Light Materials: Treatments Optimizing Performance. A pdf of this brief can be accessed and printed HERE; the complete Powerpoint presentation is available by clicking HERE.

ABSTRACT: While light metals such as aluminum and titanium alloys are essential to many industries and applications, the coatings required to provide useful functional properties (especially corrosion resistance) can be costly in terms of energy, raw materials, or health and safety; and challenging to apply consistently and with satisfactory adhesion. Cirrus Hybrid™ coating technology for light metals low cost alternative that electrodeposits an engineered thin-film coating that bonds tightly to the substrate and provides excellent corrosion and wear resistance along with superior electrical and thermal performance. As a new process, the Hybrid™ technology offers a stable, low-cost option to manufacturers and applicators seeking to improve and extend their use of light metal substrates. This paper updates the art on this innovation and shares a widening scope of application for this novel coating technology.

Featured Content

Introduction

While light metals such as aluminum and titanium alloys are essential to many industries and applications, the coatings required to provide useful functional properties (especially corrosion resistance) can be costly in terms of energy, raw materials, or health and safety; and challenging to apply consistently and with satisfactory adhesion. This article describes a new light metals coating technology, Cirrus Hybrid™*** coating that offers a low-cost alternative that electrodeposits an engineered thin-film coating which bonds tightly to the substrate and provides excellent corrosion and wear resistance along with superior electrical and thermal performance.

The primary goal of any engineered surface technology is to produce / enhance the desired surface properties of a bulk metal workpiece. These important product attributes are controlled by the coating system, and may involved one or more of the following:

- Wear resistance

- Tribology

- Magnetic properties

- Solderability

- Weldability

- Hardness

- Thermal properties

- Corrosion resistance

- Appearance

Hybrid coating technology is applicable to a myriad of coating applications and offers low cost solution which is relatively non-toxic and non-hazardous when compared to traditional anodizing, electroless nickel or primer and paint systems.

The process

Recent decades have significantly advanced anodization research and technology leading to an increase in knowledge on the underlying process. It is now possible customize the bath chemistry and operating parameters to exert fine control over the anodizing nano-arrays in terms of pore size, wall thickness and the like. This control has led to the development of the HybridTM technology discussed here. Essentially the method is a hybrid of anodizing and electrodeposition.

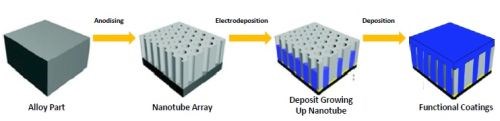

Figure 1 - Idealized schematic diagram of the HybridTM light metals coating technology.

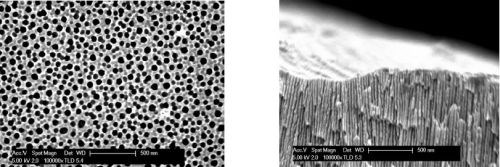

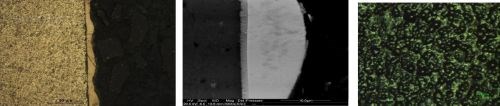

As shown in Fig. 1, an aluminum alloy workpiece (or titanium, as will be discussed later) is first anodized, creating tight nanotube structure. Surface and cross-sectional views of the nano-array are shown in Fig. 2.

Figure 2 - SEM photos of the anodized layer showing the nanotube array: (L) surface view; (R) cross-sectional view.

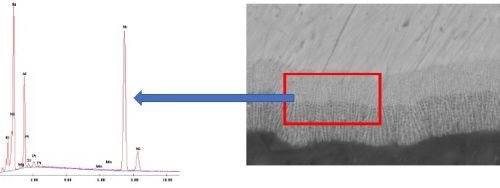

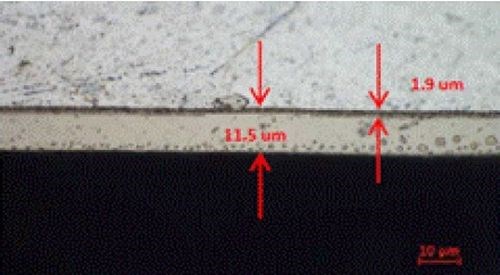

The nanotube array provides a highly effective template for deposition of a tightly coupled electro- or electroless interlock metal layer. Proprietary control of the deposition parameters allows the initial metal layer, e.g., nickel, to completely fill the individual nanotubes (Fig. 3) and reconnect with the substrate. This forms the basis for subsequent deposition of nickel or other metal over the surface. This functional upper layer can be any material, plated or coated directly onto the protected light metal substrate. Figure 4 shows a typical result, with a thin 1.9 μm anodized layer under a 11.5 μm final coating (view inverted).

Figure 3 - Cross-sectional view of nanotubes partially filled with electrodeposited nickel.

Figure 4 - Anodized, filled layer between the bulk aluminum alloy substrate (top layer in of photograph) and the final deposited coating (lower layer).

The result is a simple, relatively low-cost process which uses existing production processes and equipment, yielding high performance from a relatively thin coating.

The properties

Corrosion resistance

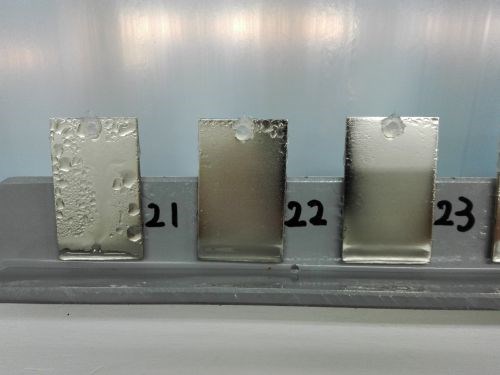

The corrosion resistance of duplex nickel coatings on the hybrid-anodized aluminum were evaluated according to ASTM B-117. Coupons anodized to a thickness of 2 μm were plated with 6.0 μm of duplex nickel (4.5 μm of semi-bright (columnar) nickel plus 1.5 μm of bright (laminar) nickel). The specimens passed 120 hr of neutral salt spray exposure. A second set of coupons were anodized to a thickness of 2 to 3 μm and plated with 10.0 μm of duplex nickel (7.0 μm of semi-bright (columnar) nickel plus 3.0 μm of bright (laminar) nickel). The specimens passed 500 hours of neutral salt spray exposure; they also passed 75 hr of CASS (copper sulfate-acetic acid salt spray) exposure. Thus, by controlling the anodized and metal layers the salt spray performance of the coating may be customized.

Figure 5 - 6-micron hybrid Al2O3 with semi-bright and bright nickel after 102 hr of salt spray testing.

Conductivity

Normally an anodizing film is nonconductive, one of the unique properties of the Cirrus Hybrid™ coating is that the deposition process redevelops the conductive path to the substrate. This is partly as a result of the structure of the anodizing film which minimizes the thickness of the barrier layer but also due to the electro-deposition process which dissolves the remaining barrier layer as the first metal layer is being deposited. One outcome of this connection is very high conductivity, another is the ability of the coating to pass a lightening test according to EN 2591-214 waveform 5B.

Thermal cycling

Referencing the 6- and 10-μm hybrid duplex nickel coatings above, specimens were subjected to a thermal cycle regimen according to Mil-Std-883, Method 1010, Condition F - five cycles at:

- 30 min at -65°C

- 2 min at +25°C

- 30 min at +175°C

- 2 min at +25°C

All samples passed this test with no cracking or loss of adhesion.

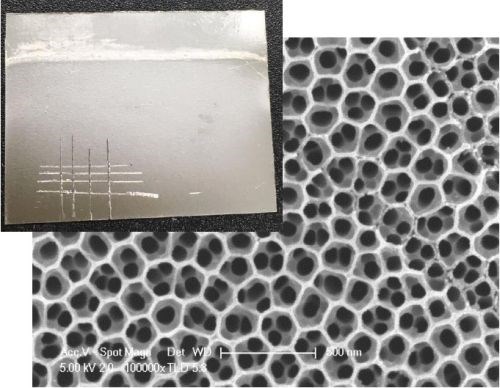

Adhesion

Adhesion properties were evaluated according to ASTM B-571. Samples were tested (a) as-coated, (b) after thermal shock testing and (c) after neutral salt spray testing. All samples passed both the scribed grid and mandrel bend tests prescribed in ASTM B-571.

Appearance and morphology

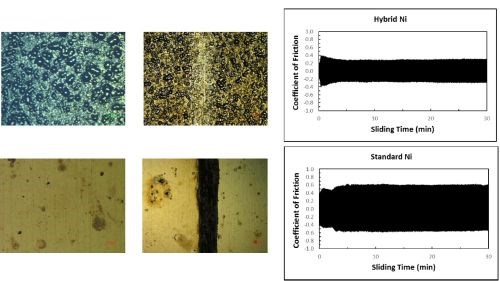

By tightly controlling the deposition parameters during the initial stages of the deposition into the nanotube array, the underlying surface morphology can be modified to affect the eventual morphology of the final coating. In this way, the surface condition can be made to produce hydrophilic, hydrophobic or other desired surface properties (Fig. 6). We call this a hemispherical surface morphology.

Figure 6 - Examples of surface morphologies produced by controlling the underlying surface: (left) wave, (center) hemispherical, (right) nodular.

The nodular surface is of interest in terms of friction properties. Figure 7 compares the nodular hybrid nickel with a standard bright nickel coating on aluminum.

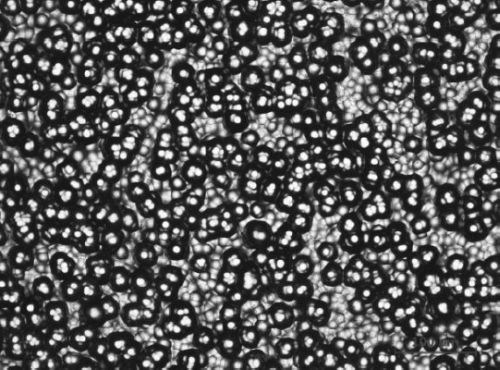

Producing a similar morphology with a black nickel deposit can significantly increase the light absorption properties of the surface, which is of primary interest in solar coatings (Fig. 8).

Figure 7- Comparison of friction properties for the HybridTM nickel (upper) versus standard bright nickel on aluminum (lower).

Figure 8 - (Left) Surface morphology of a HybridTM black nickel and (Right) the UV-Vis-infrared light absorption properties Hybrid™ black nickel (red) versus standard black nickel.

Another important attribute of this tunable surface morphology is the ability to create drag lowering surfaces. Tests at Cirrus have shown a 7% drag reduction of the hemispherical surface in a laminar water flow at 1 m/sec when compared to a flat surface. Higher reductions occur at higher flow rates.

Hybrid titanium

In addition to aluminum, the work reported here also included Hybrid™ on titanium substrates. Here the focus was on both nanotube formation and electrodeposition parameters which create a hybrid surface.

Initial work focused on a single anodization process with a copper electrodeposit including the following steps:

- Electropolishing

- Anodizing

- Post-treatment (ethanol washing and HF activation

- Electroplating with copper pyrophosphate chemistry

Figure 9 - Results for hybrid plating of copper on titanium.

The results, shown in Fig. 9, were not ideal. Short plating times supported the formation of copper nano-particles on the surface and in the nanotubes. While this was not the continuous coating we were expecting, these particles did significantly improve interesting bacteriological properties (anti-fouling, etc.). Furthermore, the nano-particles could facilitate plating of other metals on the anodized titanium. Longer plating times produced a uniform copper layer; however, this layer exhibited poor adhesion to the titanium. Figure 9 also shows that there was poor adhesion between the substrate and the anodized layer.

Work was also carried out using a double anodizing process and a duplex nickel electrodeposited layer on titanium including the following steps:

- Anodizing

- Oxide removal

- Anodizing

- Post treatment

- Annealing

- Electroplating

Here, the results were generally positive, as shown in Fig. 10. Adhesion between the annealed anodized film to the substrate was excellent, and the annealing process was key producing an adherent electrodeposited coating. This process significantly increased surface wettability which improved the filling of the nanopores. However, it was noted that problems did exist with bending adhesion tests after plating.

Figure 10 - Results for hybrid plating of duplex nickel on titanium.

Hard composite surfaces

The functional upper layer in hybrid systems may be any material, plated or coated directly onto the protected light metal substrate. These can include gold, silver nickel (as NiB, NiCo, NiP), cobalt (CoP, CoW), chromium, copper, zinc, tin, etc.

Such coatings may be doped using a proprietary dopant.† which, when added to the plating solution, can produce an ultra-hard, nano-structured composite upper layer. The dopant, which is customized per bath chemistry, consists of a liquid suspension of ~20-nm particles which do not agglomerate. The dopant is designed to be stable and the particles are highly dispersed in the bath. Importantly, the dopant is safe to handle.

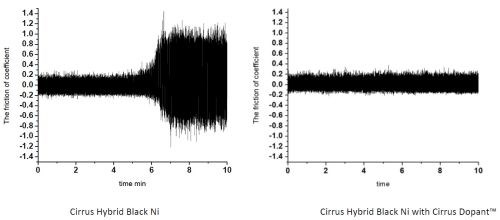

Figure 11 illustrates the dopant advantages when used with a Hybrid Black nickel coating. The coating was created by using a commercial black nickel solution as the only electrodeposited layer in the Hybrid coating stack. As with many other Hybrid coatings, the anodized layer was ~ 2µm. While the performance of the Hybrid black nickel significantly outperformed a black nickel deposited on a double zincate, for example, the addition of the dopant further improved the performance by reinforcing the black nickel layer. With the regular hybrid, the coefficient increases as the surface features are worn down after a certain test time, whereas the doped coating maintains the low coefficient of friction through the test.

Figure 11 - Hybrid black nickel augmented with proprietary dopant: (Upper) surface morphology of Cirrus DopantTM deposit; (Lower) friction coefficient comparison.

Conclusions

The Cirrus Hybrid™ coating system for light metals is a low cost, high efficiency coating system that utilizes existing production processes. The resultant coatings exhibit excellent conductivity, corrosion resistance, adhesion and thermal stability. Hemispherical functional coatings create aesthetic, mechanical and optical properties. The system can be combined with nano-structured and hardened composites, or ultra-black upper layers.

Cirrus Dopant™ is a simple additive to standard electroplating baths to convert existing coatings into hard-wearing nano-structured composite materials. When used to reinforce coatings, Cirrus Dopant™ will increase the hardness, wear and scratch resistance, and the lubricity of the coating, without altering the appearance or functionality of the coating.

Cirrus Hybrid™ is a major innovation in protection for light metal substrates and 3D printed components. Cirrus Hybrid™ offers the world’s thinnest, lightest, and most energy efficient coating system for aluminum components in electronic and functional applications.

About the authors

Chris Goode is a founder and Chief Technical Officer at Cirrus Materials Science Ltd., in Auckland, New Zealand. Chris holds an honors degree in engineering from the University of Western Australia. He holds over 30 patents and has extensive experience in multiple fields of engineering including telecommunications robotics and chemical engineering.

Dr. Fengyan Hou is a Senior Materials Scientist at Cirrus Materials Science. Previously he was Chief Scientist of the Coating Branch at Shanghai Baoshan Steel. He is an expert on corrosion and coating technology, and now works on the development of new functional surface coatings on steel, aluminum, magnesium and copper alloys. He uses techniques such as electrodeposition, anodizing, electropolishing and electroless to develop high performance coatings with superior mechanical, electrical, optical and corrosion properties.

Dr. Zhendi Yang is a Materials Engineer at Cirrus Materials Science Ltd. in Auckland, New Zealand. She completed her Ph.D. in Chemical and Materials Engineering in 2015 at the University of Auckland. Her research interests include surface engineering, alloy electroplating, composite coatings and process development.

* Compiled by Dr. James H. Lindsay, Technical Editor - NASF

** Corresponding author:

Chris Goode, CTO

Cirrus Materials Science Limited

5B Target Court

Wairau Valley

Auckland 0627, New Zealand

Phone: +64 21 248 8853

Mobile: +64 21 248 8853

E-Mail: chris.goode@cirrusmaterials.com

*** Cirrus Hybrid™, Cirrus Materials Science Limited, 5B Target Court, Wairau Valley Auckland 0627, NZ.

† Cirrus Dopant™, Cirrus Materials Science Limited, 5B Target Court, Wairau Valley Auckland 0627, NZ.

RELATED CONTENT

-

Black Chromium Finishing: Beauty and the Beast

Over the past 10 years, there has been commercial development of black chromium deposits from a trivalent chromium electrolyte. This paper will review the deposit characteristics and operational consideration of these similar, but different chromium plating deposits.

-

Aluminum Surface Finishing Corrosion Causes and Troubleshooting

In this paper, a review of several process solutions, examining coolants, solvent cleaning, alkaline clean/etch and deoxidizing/desmutting, listing intended and unintended chemical reactions along with possible mechanisms that would favor corrosion formation.

-

Direct Copper Metallization of Aluminum: Elimination of Zincate

This article discusses the development of a new copper plating bath that can deposit high ductility copper metal directly on a wide range of aluminum alloy substrates. The process is particularly important for general metal finishing companies looking to plate aluminum parts for aerospace industry.

.jpg;width=70;height=70;mode=crop)