Liquid Coating Demand Creates Albers Finishing

Kansas coater launches new, flexible and innovative liquid coatings line with help from IntelliFinishing.

#masking #pollutioncontrol #curing

So how do pizza shop owners and a potato chip maker get into the industrial finishing market?

For the Albers brothers from Cheney, Kansas, the creation of something great began with the idea to provide a product or a service that is in high demand.

Featured Content

The Albers had a conversation with a business contact who was asked to paint the parts his company was manufacturing for agricultural equipment companies. But the company wanted to focus on manufacturing parts, not painting them.

Entrepreneurs at heart, the Albers developed a business plan based on the needs of the manufacturer, and the idea to start an industrial finishing operation was born.

The result is Albers Finishing and Solutions, an industrial coating company that opened in March with a new liquid finishing line, and plans to add more services, including anodizing and powder coating.

The Albers family of four brothers and one sister has been involved in a number of businesses and is not afraid of hard work. They were excited to learn more about the finishing industry while helping the community of Cheney by creating jobs and industrial opportunities.

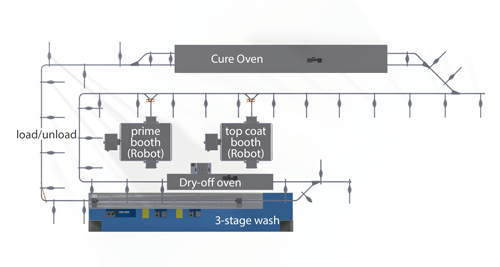

The system has a 3-stage wash, dry-off oven and two paint booths equipped with Fanuc robots applying liquid primer and paint via automated paint mix equipment.

Business Entrepreneurs

Chief among their business interests were Art’s and Mary’s Tater Chips, Leadfoot Express Transport and D’Mario’s Pizza Outlets.

The Albers have owned Art’s and Mary’s for more than 20 years. The brand was a longtime favorite on Kansas grocery store shelves and a staple at area picnics until the business struggled in 1994 and filed for bankruptcy. A few years later, the Albers purchased the rights to the Art’s and Mary’s name and resurrected the local favorite.

Their experience in the food industry resulted from owning several D’Mario’s Pizza restaurants in Kansas. They also owned Leadfoot Express Transport, a local courier company.

But the Albers knew their next venture was in finishing. They wanted to hire a company to install a finishing system that was flexible and could grow and expand as they grew.

One morning after Bret Albers dropped off his son at school, he stopped to grab a breakfast sandwich before a meeting. As he ate in the parking lot, he pulled out his mobile phone to research paint systems when he found information about IntelliFinishing in Salina, Kansas.

The highly-automated liquid coating line has a part window of 2 by 4 by 8 feet and can handle up to 500 pounds of weight on each load bar.

Modular Conveyor

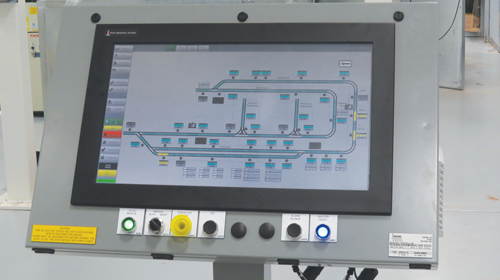

IntelliFinishing is a finishing systems provider with a distinctive modular conveyor system and smart control technology that enables individual sections of the conveyor to move independently in both speed and direction throughout the entire system.

Albers watched the videos on the IntelliFinishing website and saw a system that could be flexible and innovative. When he discovered that IntelliFinishing was located only two hours away, he immediately called his brothers for a conference call.

“Guys, stop whatever you are doing,” he told them. “This is it. This is what we need.”

Albers called IntelliFinishing later that day and spent more than an hour on the phone with a mechanical engineer. Eventually, after numerous discussions and layout revisions, a system plan was finalized and became the liquid paint system at Albers Finishing and Solutions.

Albers Finishing and Solutions christened its system with an open house in March to show local manufacturers all that the system has to offer.

The highly-automated liquid coating line has a part window of 2 by 4 by 8 feet and can handle up to 500 pounds of weight on each load bar. This high-volume system features an automated conveyor that can move load bars forward and reverse, or even stop them independently of every other load bar.

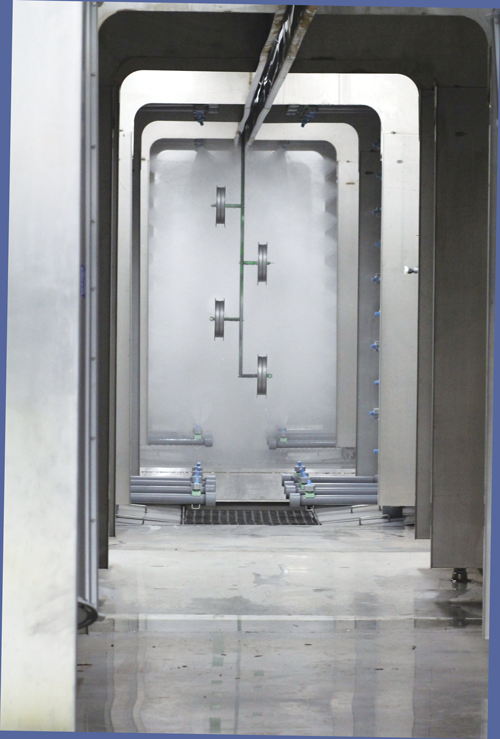

The system currently uses a cleaner/phosphate in stage one, a reverse osmosis rinse in stage two and nanotechnology conversion coating for extended corrosion resistance in stage three.

Energy Efficient

The system also has a 3-stage wash, a dry-off oven, two paint booths equipped with Fanuc robots applying liquid primer and paint via automated paint mixing equipment, a dual-lane energy-efficient cure oven and a load-assist lifter.

“This paint system offers some of the best and newest advances in the industry,” says Woody Miller, IntelliFinishing’s project manager. “With advanced automation and controls, energy efficiencies and floor space savings, the cost to paint each part is less than other systems. This is a very high-end system, located here in Cheney.”

IntelliFinishing teamed up with Downey Consulting to design the load-assist lifter, carriers, loadbars, hangers and a rotator mechanism in each paint booth. The parts are hung on a custom loadbar with a spinner wheel and are spun using the air-operated rotator.

All of this is controlled by the programmable logic controller. The wireless lifter mechanism is capable of removing the loadbar from the carrier fully loaded with parts, placing finished product on racks, or changing loadbars for a different type or style of part, which Miller says enables ultimate flexibility of the system.

“Being fully automated and robotic enables us to provide clients with a consistent product each and every time,” Albers says.

With the computer controls, the variable frequency drive pumps can be modulated for different types of parts, or shut down entirely if there are no parts.

Albers Finishing and Solutions also teamed up with Lincoln Chemical for its wash chemistry. Lincoln’s Ed Dole spent time working with the Albers team to ensure they were fully trained on how to check pH levels, titrations and what to watch for when the tanks need to be drained. The system currently uses a cleaner/phosphate in stage one, a reverse osmosis rinse in stage two and nanotechnology conversion coating for extended corrosion resistance in stage three.

The washer is stainless steel with insulated upper housing, and was designed for future additions. With the computer controls, the variable frequency drive pumps can be modulated for different types of parts, or shut down entirely. The computer also controls additions of chemistry, eliminating potential human errors.

“We did extensive testing of the pretreatment process prior to Albers choosing the wash process,” Dole says. “This took a team effort between Lincoln Chemical and PPG.”

Midwest Finishing Systems designed the 3-stage washer, using a pressure washing system with wash bay, liquid and powder paint application equipment and the convection cure oven. Panels were pre-qualified in Lincoln Chemical’s salt spray cabinet to ASTM B-117.

Albers Finishing and Solutions says its starting goal is to focus on superior quality, consistency, and customer service. “Our goal is to be a partner, not just another contractor,” Albers says. “We understand how important turnaround times, communication on the status of a product, quality control and proper packing are to the success of a business.”

For more information on Albers Finishing and Solutions, visit albersfinishing.com. For information on IntelliFinishing, visit intellifinishing.com.

Originally published in the June 2016 issue.

RELATED CONTENT

-

Powder Coat MDF for an Enviable Finished Product

Cabinet maker says powder coating on wood offers more benefits.

-

Reducing Powder Coating Waste

Coating application is often overlooked as a potential money saver, but recognizing opportunities within this area is crucial to an efficient operation.

-

Better Alloy Control of Alkaline Zinc Nickel Baths

The factors that influence nickel content in deposits from alkaline non-cyanide zinc nickel baths.