To understand where Morton Industries is today is to understand the long journey from where they began. It includes more twists and turns than the tubes they fabricate for their large OEM customers.

We’ll talk about their finishing line and its new automated systems in a bit, but first there is a backstory that needs some explanation, including acquisitions, reacquisitions, bankruptcy, fire and survival through several economic downturns in the automotive and construction sectors.

Featured Content

“When Caterpillar sneezed, we caught a cold,” Kevin Baughman, the plant general manager, told the Fabricator in 2017.

Founded in Morton, Illinois, in 1946, the company specializes in tubular fabrications and sheet metal components for OEMs in general manufacturing, mining, construction, agriculture, automotive and energy sectors.

The family owned company decided in 2004 to sell what was then known as Morton Welding to the private equity investment group Thayer Capital, which sold them to BHM Technologies (which also owned Michigan-based stamper Brown Corp. and Tennessee-based stamper Heckethorn Manufacturing).

When the automotive market tanked a short time later, BHM sought bankruptcy protection, despite the fact that Morton was turning a profit for its owners. The original owners purchased Morton and brought it back under local ownership, and even added Bradley Services, another tube manufacturer.

Global Expansion

The new Morton Industries grew substantially in the mining and construction industry, with new accounts and partnerships that actually caused issues when some of their OEM customers wanted them to open plants in Asia and India. Morton owners struck a deal to be purchased by Nelson Global Partners (NGP) in 2011. NGP already had operations in India and China, so global expansion would be easier for Morton with them than going it alone.

Things were going well for Morton and NGP until, just like the automotive market, the construction sector began to take a downturn in 2014 when the commodity bubble started leaking. With Morton well entrenched in handrails and other tubular features for heavy industry, things began to look tight again, which led NGP to sell Morton (along with Peoria Tube) back to their original owners in 2016.

All that wheeling and dealing forced Morton Industries owners to align their operations in a much leaner configuration. That included installing new equipment and taking advantage of the latest technology to make operations more efficient and profitable.

After a fire at the facility in 2013, Morton took part of the insurance settlement and installed its own powder coating line to bring that aspect of the manufacturing process in-house.

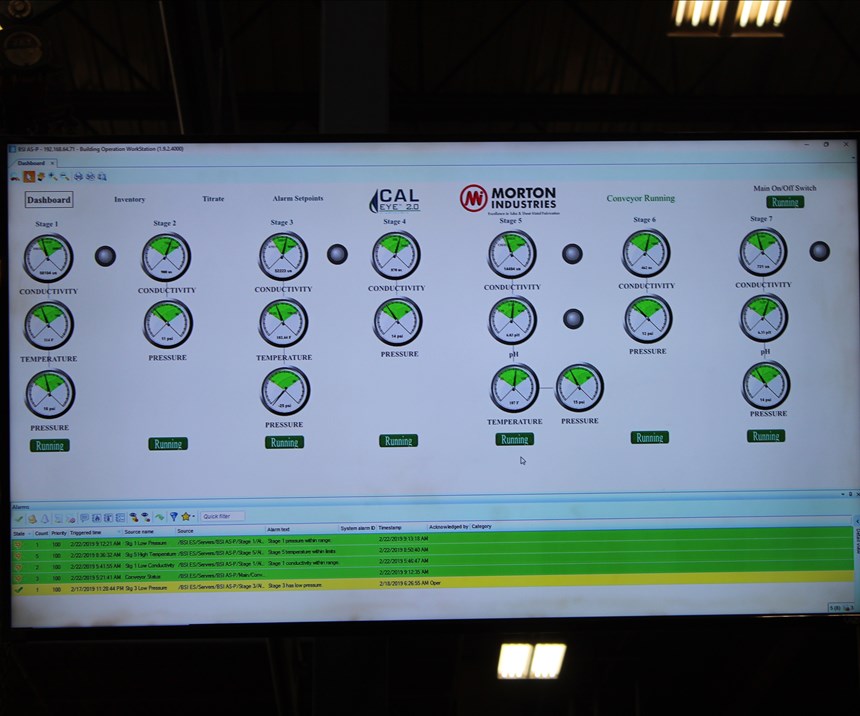

Part of that plan was for new enterprise resource planning systems and, in the finishing area, the installation of Calvary Industries’ CalEye 2.0 control system, which monitors and controls several process parameters, including temperature, conductivity, pH, pressure, conveyor status and tank levels.

Controlling Costs

Baughman says the monitoring process was all being done manually, including checking chemicals, temperatures and conductivity.

“Those needed to be controlled for good output for a good paint finish,” he says. “But one of the things we wanted to examine was our costs. We needed to know if we were adding chemicals too soon or not soon enough.”

Tom Boland, Calvary’s national sales manager, says they started working with Nelson Global four years ago because of Calvary’s Caterpillar approvals, and have continued working with them since the company was purchased again three years ago. Calvary converted the Peoria Tube facility to its systems, including a unique seven-stage washer that removes laser oxide and applies a Caterpillar Class-A pretreatment followed by a gel coat and topcoat powder operation.

The CalEye 2.0 system at Morton and Peoria is one of the first installed since Calvary brought the engineering of the system in-house to create new features and benefits for its customers.

“A lot of the new graphing and reporting functions have been upgraded and are pretty incredible,” Boland says. “When we took the engineering of the CalEye project internal, we spent about a year redesigning features and we are very happy with what we can offer our customers.”

Automatic and Timed Chemical Feeds

CalEye 2.0 provides automatic or timed feed of chemical pumps and opening of water valves, as well as providing a Supervisory Control and Data Acquisition (SCADA) feature with a centralized workstation computer for monitoring, with values stored in trend logs that are easily exportable. The system’s data is archived in a server database for long-term history, and includes system alarms and reports.

The benefits to customers, such as Morton and Peoria, include reductions in (1) water use thanks to valve control on rinse stages and halo control; (2) downtime because of the automated control of washer conditions that decreases line stoppages and produces real-time data with alarms to identify and analyze potential problems; and (3) reject rates because optimal washer conditions result in fewer rejected parts and less rework.

The seven-stage washer system starts with a multimetal alkaline cleaner to remove oils and soils, and then heads into an acid pickling area.

“It can be problematic to remove laser oxide,” Boland says. “A lot of facilities have problems with flash rust and line stops, but we feel we have solved those problems with a combination of the chemicals and an automated system that really controls the process.”

Before parts move into the coating area, they get a traditional phosphate and nonchrome sealer that is Caterpillar Class-A approved, something Boland says is unique.

“On the Caterpillar specification, we are the only supplier in the world that has a phosphate sealer combination that is Class-A approved,” he says. “Traditionally, it has only been zinc phosphate that has reached that level.”

Two-Pass Gel and Powder Coat

Baughman says the cleaned and pretreated parts get a two-pass gel coat and powder topcoat to finish the operation.

“With this new system, the parts coming out are 10 times better than they have ever been,” he says. “We just weren’t having consistent temperatures on certain stages, so the chemicals weren’t acting the way they should, or at least not consistently.”

Baughman says the CalEye 2.0 system has also alerted them to other items that needed adjustments or fixes, such as filtrations and screens. The system even helped them detect a leak they had in one of their header pipes that had to be brought under control.

“It was just dumping chemical, but the system caught it for us,” he says. “I’m sure we would have caught it several months down the road when we asked ourselves why we were spending so much on that particular chemical, so the system has proven to be a cost saving for us in that regard.”

Baughman and his team are now poring over data and trends they didn’t have access to before to see how they can get even more cost savings. The Morton and Calvary teams sit down each month and review data generated from the Cal Eye 2.0. Collaborating to review the information has given Morton the ability to quickly assess and make needed changes.

With the alerts and warnings, they are also able to fix certain issues immediately. A large video monitor on the shop floor is visible to many, and the finishing team can react quickly, if warranted. They can even log in remotely from their homes and check systems if they wish.

“We have seen a spike in our chemical spend,” he says. “But now we can go back with our monitoring system and start to dial it in. Maybe the specs are way too wide, and we can start tightening those up, but now we have the chance to make those adjustments with all the new data we are getting.”

Visit mortonind.com and calvaryindustries.com.

RELATED CONTENT

-

Anodizing Vs. Powder Coat

I am an engineer on a large yacht build project and urgently need information and advice on choosing a finish for the aluminum deck plates in the engine room.

-

The Powder Coating Process

Powder coating is one of the most durable finishes that can be applied to industrial manufactured products, and offers excellent corrosion protection and is very safe because of its lack of volatile organic compounds. To understand the powder coating process you should start with the fundamentals.

-

Understanding Infrared Curing

Infrared cure is gaining increased attention from coaters as a result of shorter cure cycles and the possibility of smaller floor space requirements when compared to convection oven curing.