Nickel: Science, Health and the Future - The 52nd William Blum Lecture

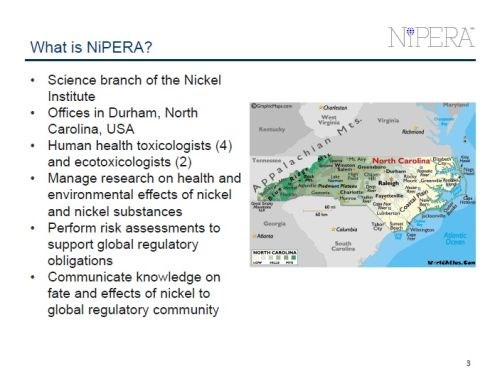

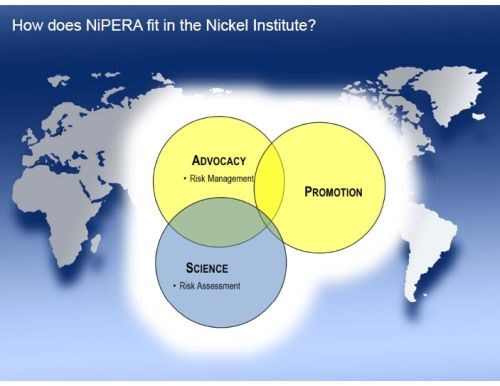

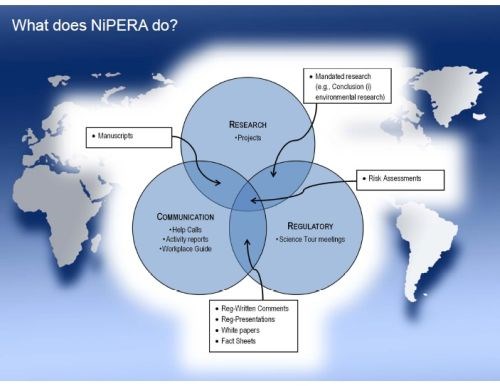

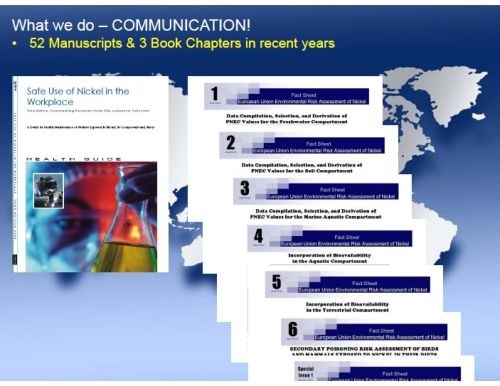

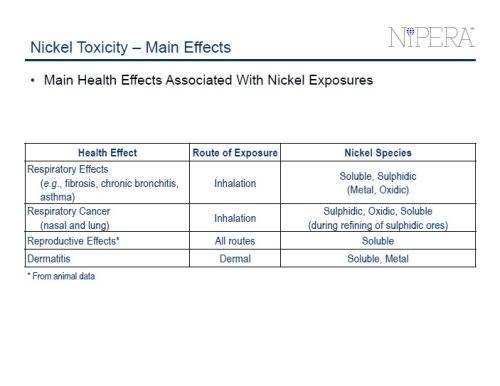

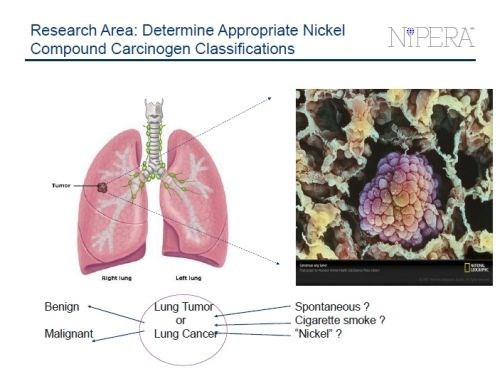

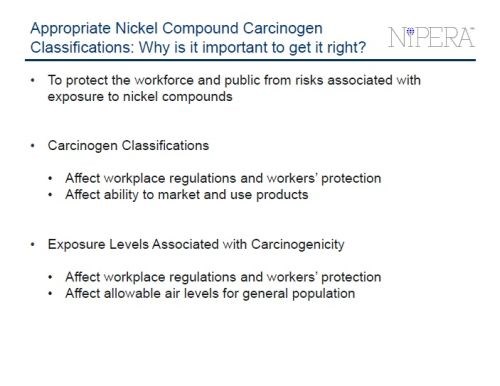

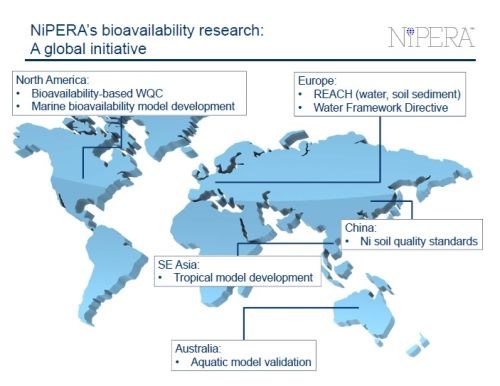

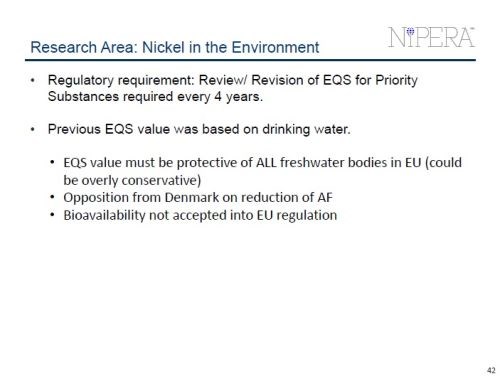

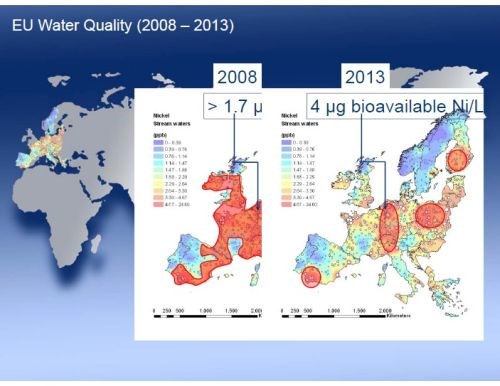

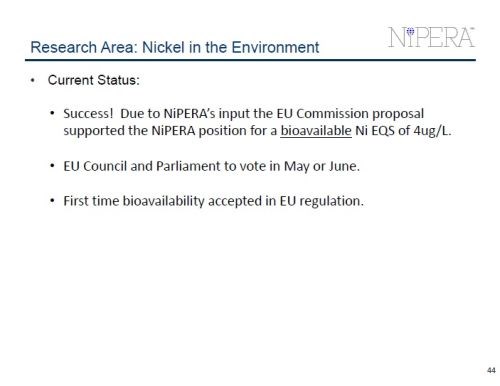

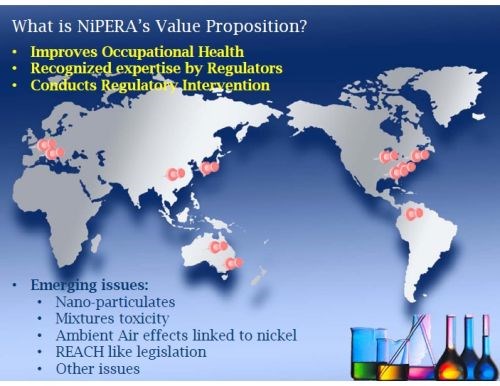

This presentation is the 52nd William Blum Lecture, presented at SUR/FIN 2015 in Rosemont, Illinois on June 8, 2015. In this lecture, Dr. Hudson Bates discusses the nickel research in his group at the Nickel Producers Environmental Research Association (NiPERA), which impact occupational health and environmental issues for nickel. This includes nano-particulates, toxicity of mixtures, ambient air effects, and providing good science in regulatory matters.

#surfin #research #medical

by

Dr. Hudson Bates

Featured Content

Recipient of the 2014 William Blum

NASF Scientific Achievement Award

Editor’s Note: The following is the Powerpoint presentation by Dr. Bates in delivering his William Blum Memorial Lecture at SUR/FIN 2015, in Rosemont, Illinois on June 8, 2015. A printable version of the presentation is available by clicking HERE.

About the author

The NASF Scientific Achievement Award is the Association’s most prestigious award. Its purpose is to recognize those whose outstanding scientific contributions have advanced the theory and practice of electroplating, metal finishing and allied arts; have raised the quality of products and processes; or have advanced the dignity and status of the profession.

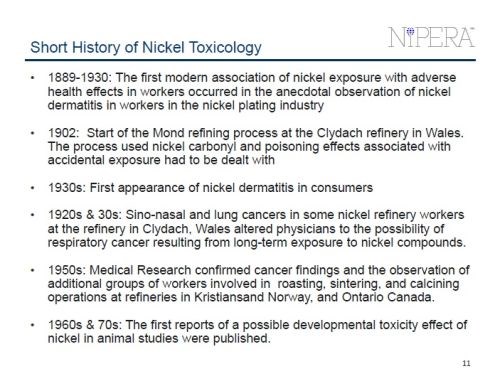

Dr. Hudson Bates has more than 30 years of experience in toxicology, with specialization in developmental toxicology, reproductive toxicology, and neurotoxicology. During more than the past two decades, this specialized knowledge has been applied to the study of the toxicology of nickel and its compounds.

Dr. Bates received his Ph.D. in toxicology from the University of Arkansas for Medical Sciences, his M.S. in toxicology from the Albany Medical College of Union University, and his B.S. in biology from the State University of New York at Albany. Dr. Bates became a Diplomat of the American Board of Toxicology (D.A.B.T.) in 1992 and has successfully completed the recertification testing in 1997, 2002, 2007, 2012, and 2017. Dr. Bates has also had specialty training in advanced behavioral and neurophysiological testing methods for neurotoxicants.

Dr. Bates has been employed by the Nickel Producers Environmental Research Association (NiPERA) since 1994 and is currently the Executive Director of the organization. He is responsible for guiding the research and communication activities of five doctoral level scientific staff and for guiding the strategic research direction of NiPERA. Dr. Bates has maintained a high level of personal scientific interaction guiding research programs and addressing regulatory issues on human and environmental toxicology.

In previous positions, Dr. Bates directed and/or managed toxicology laboratories at the U.S. FDA’s National Center for Toxicological Research (NCTR), Research Triangle Institute (RTI), and Transgenic Sciences, Inc. His experience includes numerous interactions with regulatory authorities, contact with various industries on scientific issues related to their commodities, extensive public speaking experience, and some product litigation defense experience.

RELATED CONTENT

-

Super Finishing: ‘Micro Machining Process’ Vital To Medical Industry

Using high-precision tools and technologies that smoothes a surface—or even intentionally leaves specific controlled amounts of roughness behind—MMP is unlike any treatment on the finishing market.

-

Nanostructure of the Anodic and Nanomaterials Sol-Gel Based Materials Application: Advances in Surface Engineering

Porous alumina can be fabricated electrochemically through anodic oxidation of aluminum. This paper reviews sol-gel chemistry and applications, which also offers unusual nanoporous microstructures. The ability to control pore chemistry at different scales and geometries, provides excellent bioactivity, enabling the entrapment of biologically active molecules and their controllable release for therapeutic and medical applications.

-

Functional Trivalent Chromium Electroplating

This paper will discuss recent research work on the development of a functional trivalent chromium plating process from a single, simple-to-control trivalent-based electrolyte to replace hexavalent chromium plating. Hexavalent chromium plating has been used for many years to provide hard, durable coatings with excellent wear and corrosion resistance properties. However, hexavalent chromium baths have come under increasing scrutiny due to the toxic nature of the bath, effects on the environment and worker health. In this work, we are updating accomplishments to achieve properties comparable to existing hexavalent chromium plating for functional applications. Work on achieving desirable thickness, uniformity, adhesion, porosity and corrosion resistance, as well as other material properties, will be discussed.