Overcoming Strict Solvent Cleaning Regulations

Aerospace manufacturer tries unique approach to meet agency regulations

#aerospace #regulation

Some cleaning applications require increased performance of chemical solvents to break down soils to manageable levels that can be readily removed before surfaces are coated or plated. But tighter regulations for solvent use have created roadblocks that can restrict usage or make it cost-prohibitive, even when it seems like the only practical solution.

For companies in certain high-risk sectors involving precision engineered components, such as aerospace, healthcare and defense, cleaning processes form a vital part of their quality assurance before a finishing application. So the ability to retain proven methods—including solvent choice—and at the same time comply with stricter local environmental agency regulations is highly desirable.

Featured Content

California Rules

Perhaps the strictest environmental regulations in the U.S. are in place in California. It’s here that a major aerospace manufacturer was able to apply an existing validated process—a highly effective and acceptable solvent cleaning solution already in use—to solve its complex issues around the specialized cleaning of precision components.

Not surprisingly, the company was intent on retaining its existing process and chemistry due to the restrictive nature of change. The solvent of choice was a flammable blend of isopropyl alcohol (IPA) and cyclohexane, a widely available, non-ozone-depleting, low-cost solvent with excellent soil-removal and cleaning capability. It was a tried and successful cleaning solvent for the company and a fully approved process.

The city of Santa Barbara’s Air Pollution Control District has strict and detailed levels of compliance for solvent emissions (Rule 231 for solvent degreasing). In fact, the compliance criteria extends much further than most other regulatory bodies, which tend to manage environmental impact by means of measuring and capping solvent losses, emissions or exposure levels.

For a company to comply with these controls, it is essential that sound advice is taken from a vendor with sufficient knowledge and experience. In this case, the company’s manufacturing technical team involved Layton Technologies to support it in finding a suitable system to continue to meet its cleaning needs.

“The challenge was to develop an effective cleaning solution, but with significantly lower emissions than the current system in order to meet the stricter control limits,” says Phil Dale, Layton’s managing director. “These limits had a significant impact on the cleaning system’s design and manufacture.”

In addition to final solvent usage limits, it set quite challenging requirements involving the machine’s freeboard ratios, enclosure system and exhaust methods. The system was also designed to operate at class 10,000 cleanroom standard, and the customer’s engineering group also had to set parameters to minimize the impact that a new cleaning system might have on the overall manufacturing operations.

This involved minimizing machine supervision and time-consuming maintenance interventions.

The Solution

Options were limited because few systems are available that are able to meet all of the restrictive criteria while operating with the use of flammable solvents. But the ability to use the existing solvent in a compliant system removed the need for complex vacuum system technology, thermal oxidizers and carbon absorbers.

Through consultation with the customer, planning, testing, application and review, the team from Layton was able to design and develop a tailored version of its Bluestone ultrasonic flammable solvent cleaning system to provide a cleaning process that not only meets the strict legislative guidelines, but also duplicates the existing validated process already in use.

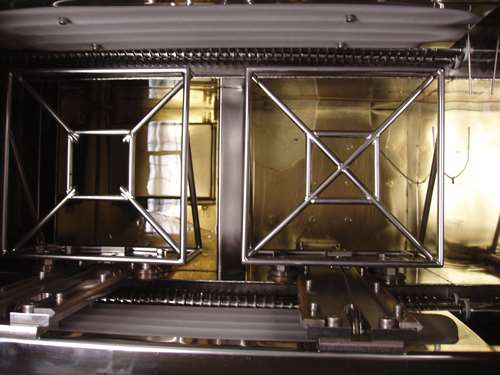

Dale says the system is designed to handle a flammable solvent in a controlled, safe and environmentally compliant way. Solvent usage is managed through a set of barriers: a sealed sliding door that provides access to an upper freeboard area within the machine.

This area is generally free of solvent vapor, therefore limiting emissions from the system when the door is open. It is at the top of this freeboard where the work basket carrying the components is automatically transferred to an internal handling system. Only after the door is sealed does the basket lower through the vapor and into the process tank where components are cleaned using ultrasonics and sprays.

The work basket then travels vertically to the solvent vapor phase. As part of achieving environmental compliance, the process requires a super-heated vapor phase that is tightly monitored at 10°F higher than the boiling point of the solvent.

“This has the effect of driving up the surface temperature of the components so that, as they pass through the chilled areas, the solvent is more rapidly and completely removed and contained,” says Ian Parry, Layton’s marketing development manager. “After the pre-determined dwell in the vapor phase, the basket then travels vertically again to the freeboard area where all solvent is evaporated from the surface.”

Only after a pre-determined dwell in the freeboard area is the operator allowed to open the door to retrieve the basket carrying the cleaned parts.

“Based on our experience, this technology will minimize downtime and maintenance, thereby adding as much as 30 percent to machine utilization, with operating costs cut by a high percentage as well,” Parry says.

The intuitive design of the Bluestone system enables operators to perform many of the day-to-day maintenance tasks themselves, avoiding costly downtime. An advantage of the Layton system design is that the PLC and HMI do a substantial amount of the work.

“The clear HMI functionality of the system is designed for simple control and process status display, allowing efficient setup and monitoring of the cleaning process,” Dale says. “Routine maintenance is mainly limited to checking and replacing filters, with service intervals for overall inspection scheduled every six months.”

Along with legislative compliance, the Layton system also offers improved safety and operational cost-savings.

Parry says the safety features in a flammable solvent system are crucial, so in this instance, the solvent vapor leak detection and CO2 fire suppression had to meet national approvals, in addition to gaining the endorsement of the local fire department and the company’s insurers.

Significant savings have been realized by reducing solvent usage by more than 50 percent and reducing labor costs regarding machine supervision and maintenance. And because the system offers a smooth, programmable operation, throughput is more regulated and bottlenecks are reduced, also contributing to overall productivity gains.

Since alcohol-based solvents can absorb small amounts of water naturally introduced into the system from the operating environment, a desiccant drier was also incorporated. This feature helps to prevent moisture from affecting the parts and to generally prevent any build-up of moisture in the process.

General Product Details

The Bluestone system is designed for environmentally compliant, safe and effective solvent cleaning. It is customizable to fit the needs of a given application and flexible to adapt to changing production needs. Systems can be designed to clean a wide range of components, from miniature substrates to large industrial castings in a variety of processes. If agitation of the cleaning fluid is required, then ultrasonics, sprays, sub-surface sprays or a combination can be used.

The modular setup lends itself well for cell-based manufacturing. Centralized or multi-station systems can be used for higher-volume or in-line applications, and a range of integrated material handling systems is also available. n

For more information from Layton Technologies, visit laytonprecisioncleaning.com.

RELATED CONTENT

-

Evaluation of Hexavalent Chromium Free Bond Primers for Aerospace and Defense Applications

Three hex chrome free bond primers demonstrated that they can surpass the 960 hour threshold before exhibiting panel corrosion away from the scribe.

-

Aerospace: Base Coat-Clear Coat System Offers Benefits for Aircraft

This system improves buffability and extends service life.

-

Direct Copper Metallization of Aluminum: Elimination of Zincate

This article discusses the development of a new copper plating bath that can deposit high ductility copper metal directly on a wide range of aluminum alloy substrates. The process is particularly important for general metal finishing companies looking to plate aluminum parts for aerospace industry.