Picking Up Productivity

The original lean manufacturing philosophy, "The Toyota Way" has come to symbolize a way of doing business in manufacturing that produces the highest quality and financial success.

#management #automotive

The original lean manufacturing philosophy, "The Toyota Way" has come to symbolize a way of doing business in manufacturing that produces the highest quality and financial success.

Developed over a period of a couple of decades, The Toyota Way is based on 14 key principles designed to facilitate continuous improvement across a manufacturing operation (see sidebar). These principles led managers at the Toyota Industrial Equipment Manufacturing (TIEM) facility in Columbus, IN to upgrade the paint process for their forklift products by putting together a team consisting of engineers, maintenance and operator personnel as well as a handful of trusted suppliers.

Featured Content

Background

TIEM, which had relied on air-assisted airless spray technology in both its manual and automatic paint booths for years, realized it could improve paint quality and efficiency by upgrading to electrostatic applicators. Unfortunately, the company's first generation of electrostatic guns performed poorly and required a great deal of expensive maintenance.

"The increased transfer efficiency that resulted from switching to electrostatic spray drove a lot of related cost factors," explains production engineer Jason Niccum. "Obviously, it reduced paint use, but it also cut down on the time needed to apply the paint as well as the time and cost needed to clean up overspray. It also reduced costs and downtime related to replacing gun wear parts and other spray system components such as pumps and related equipment. But finding the right electrostatic solution turns out to have been just as important a task as identifying electrostatic spray in the first place."

As Niccum points out, the decision to change technologies from air-assisted airless to electrostatic paint application was only the first step in the Toyota improvement process. Managers assembled a team of workers and trusted suppliers to help find the best solution.

"We designed an evaluation matrix that rated each spray gun on a number of important factors," Niccum explains. "The matrix included everything from purchase cost to operating cost, ergonomics and maintainability. Then we contacted many of the industry suppliers we had worked with over the years to bring in products that best fit our needs."

One of those suppliers was FinishLine Technologies (Columbus, IN), which had worked with the finishing team on upgrades to TIEM's robotic spray line.

The company was also involved in improving paint processes in the plant's two manual booths, where large components such as heavy counterweights are painted.

Process Upgrades

The TIEM paint improvement team chose FinishLine and Wagner Industrial Solutions (Elgin, IL) to provide both the manual and automatic guns used in the paint process improvement project. Wagner's AirCoat guns use a distinctly lower air pressure for atomization than conventional airless equipment. Additional atomizing air produces a soft and very uniform spray pattern, which leads to more consistent film builds, better electrostatic wrapping, less overspray and a faster coating process overall.

Each gun is controlled by a Wagner VM2000 power supply that allows operators to easily see and set any of the key electrostatic spray parameters such as electrostatic voltage (kV) and actual current draw while spraying. The display also allows tracking of a range of possible fault alarms and a grounding check to ensure better coating uniformity.

Reduced overspray from the robotic AirCoat guns is particularly beneficial on Toyota's robotic chassis paint line, because those guns are typically applying paint to structural metal frames. "We used to put more paint into the air than on the part," Niccum recalls.

On the manual spray line, the ability of the guns to produce a soft run-out at edges lends itself well to the common wet-on-wet two-tone paint process TIEM uses for heavy counterweights and other lift truck components.

Compared with its original air-assisted airless spray guns, Toyota has recorded more than a 53% overall improvement in transfer efficiency. This upgrade was also marked with a noticeable improvement in finish quality and a reduction in ongoing ownership costs.

The guns' durability has also played an important part in TIEM's paint process improvements. Each of the one- to eight-ton lift trucks produced each day at the plant is already sold. This made-to-order philosophy creates pressure to produce product quickly and keep rework to a minimum.

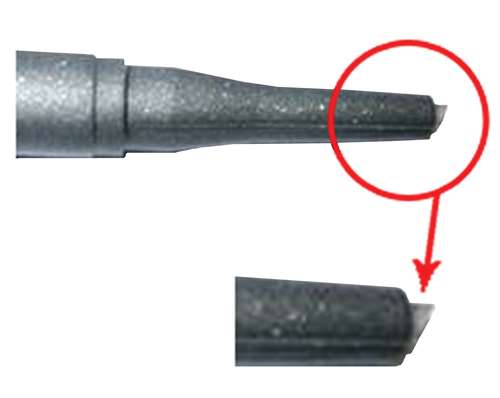

"One feature of the equipment we couldn't evaluate up front but have come to appreciate is its durability," says paint department assistant team leader Mike Malone. "Downtime to replace a worn out spray gun tip is a nuisance. We have gone from replacing gun tips every three or four days to running for weeks at a time. Our parts costs have fallen by thousands of dollars a year because of the equipment's design and reliability."

RELATED CONTENT

-

National Association of Metal Finishers (NAMF)

Founded in 1955, the National Association of Metal Finishers (NAMF) is comprised of management executives in the surface finishing industry and related fields.

-

Bridging the Sales-Operations Divide

Matt Kirchner recently assembled a group of manufacturing industry sales and operations professionals to define "Rules of Engagement," a group comprised of seven individuals with combined experience exceeding 120 years. Here's what they came up with.

-

Be Prepared: Managing Environmental Inspections

Is your shop ready for an environmental inspection? Preparation and documentation can help minimize your facility’s risk of noncompliance.