Darrick Gula has been on both side of the electroplating fence, as an OEM specialist who wrangled with suppliers and now in his position with a major automotive supplier.

The former head of General Motor’s (GM) global process for chrome plating and anodizing is with German-based Bolta U.S. as director of business development for the global manufacturer’s new plant in Tuscaloosa, Alabama.

Featured Content

Gula completes a management team that on the top level consists of Gudrun Pechtold, plant manager and chief financial officer; Michael Crawford, vice president operations and logistics; and Martin Russell, vice president human resources.

“I’ve walked a mile in both sets of shoes,” says Gula, who left GM in 2017 to help lead the German parts supplier’s efforts in the U.S. “It helps to have been on each side and see what the challenges are. Not a lot of people in the industry have experience like that, but it has certainly helped me.”

Like its other worldwide plants, Bolta’s $48-million Alabama plant specializes in injection molding, plating on plastic (PoP) and assembly. It opened in 2017 and has over 350 employees and more than 220,000 square feet of production space for the manufacturing of automotive nameplates and decorative trims that must be plated, including badges, grills, wing mirrors and trims for Mercedes, Audi and Volkswagen.

Challenges of Plating on Plastics

The move to Alabama was expected of Bolta, especially because more than 20 automotive suppliers have already located in Tuscaloosa County since Mercedes started producing vehicles at their Vance plant in 1997. The Tuscaloosa County Industrial Development Authority says the suppliers employ almost 5,000 and have invested more than $700 million in facilities in the last decade.

“The region has a growing reputation as a quality-driven center for premium-class automotive manufacturing,” says Pechtold, one of the few female top-level executives in the automotive suppliers’ arena. “We feel that it is the perfect place to develop Bolta’s U.S. footprint. We have settled in well by now, and value the innovative atmosphere.”

But starting up a new facility always comes with challenges, especially when it comes to the tricky PoP process that has a lot more idiosyncrasies and requires more expertise than typical metal finishing applications.

“It’s a challenge because so much is seen by the car-buying public,” says Crawford, who points out that the employees in production strive to set a higher standard. “It’s the brand recognition items on the decorative surfaces — the emblems, grill and features – that is what people are looking at the most. It has to be perfect.”

Maybe it is the employees’ special approach that makes all the difference. At Bolta, each staff member belongs to the unique “Bolta Force.” Highly energetic, their work ethos is visible all over the facility with the mantra ‘One mission, one team, one Bolta Force.’

The Bolta U.S. plant has 20 injection molding machines churning out products every day, and a plating line built by Atotech to finish the parts before they are shipped to nearby automotive assembly facilities. Most automotive OEMs require the same supplier to make the injection molded part and then finish them, to save on time and headaches.

“There is a lot less finger pointing when you have the same supplier who can perform the finish after they’ve made the part,” says Gula, adding that the PoP process is intricate in that it involves so many aspects — from mold design to tool design, part design and, eventually, the plating process.

“The success comes when you get two completely independent processes — the molding and the plating — being married together,” says Gula.

And Gula knows something about running plating operations. He ran the chrome line at Harley Davidson’s Pennsylvania plant and also worked in the paint shop at its Kansas City facility before adopting his roles at GM, leading him up to executive business manager for global supplier quality and managing more than 7,000 suppliers around the world.

Gula joined Bolta in late 2017 to get back into the plating industry, something he says he missed.

“We are extremely glad to have such a dedicated workforce with lots of expertise in their field of work as well as in our highly specialized industry,” says Russell, talking about human resources and career possibilities. “Combined with our focus on international collaboration with the German teams, we might still be a young member of the community, but, at the same time, becoming more and more attractive as an employer as well.”

Bolta’s Darrick Gula, left, confirs with Atotech’s Dustin Evans, who is a product specialist on plating-on-plastic.

Turnkey Plating Operation

The U.S. facility is similar to the company’s other North American plant, Nicro Bolta in Puebla, Mexico. That plant makes decorative chrome plastic parts and employs more than 1,000. It was set up in 2005 as a joint venture between two Mexican manufacturers, Croni and Ecoplating, along with Tom Gerhardt (a U.S. investor) and Bolta Werke GmbH in Germany, to supply the Volkswagen production facility in Puebla. In 2013, Nicro Bolta opened an additional plating line to provide parts for the growing truck and four-wheel drive market for manufacturers such as Audi and Chrysler.

Atotech helped launch the Nicro Bolta facility and was called on again when Bolta U.S. started planning for its Alabama operations several years ago. Josha King, Atotech’s business manager in North America for decorative coatings and PoP, says he started working with Bolta’s Germany group on the Alabama plant in 2015. Joe Arnold, Atotech’s equipment guru, also took part in the meetings, as did others on the Atotech team.

It helped that Atotech is based in Germany and many of the principals were already familiar with each other and their needs.

“Our focus was getting the Bolta specifications to exactly what they wanted it to be,” King says. “With some customers, it’s very open, and they tell us how many bars per hour and this many square meters on a bar. But, with Bolta, they are already experts in the field, so they pretty much designed the line with us and we went to work building it for them.”

The biggest challenge, King says, was bringing the German processes and systems to the U.S. and having them work in Alabama for Bolta just as they did in their other plants around the globe. That included training all the new managers and supervisors who would be working on the new Bolta line. Fortunately, Atotech has a technical training center in Rock Hill, South Carolina, that the new hires were able to work in and hone their skills.

“They were able to train on our plating lines,” King says. “The benefit was that when the Bolta plant finally got up and running, we didn’t have people training on their line as they were trying to get up and running. That made a huge difference.”

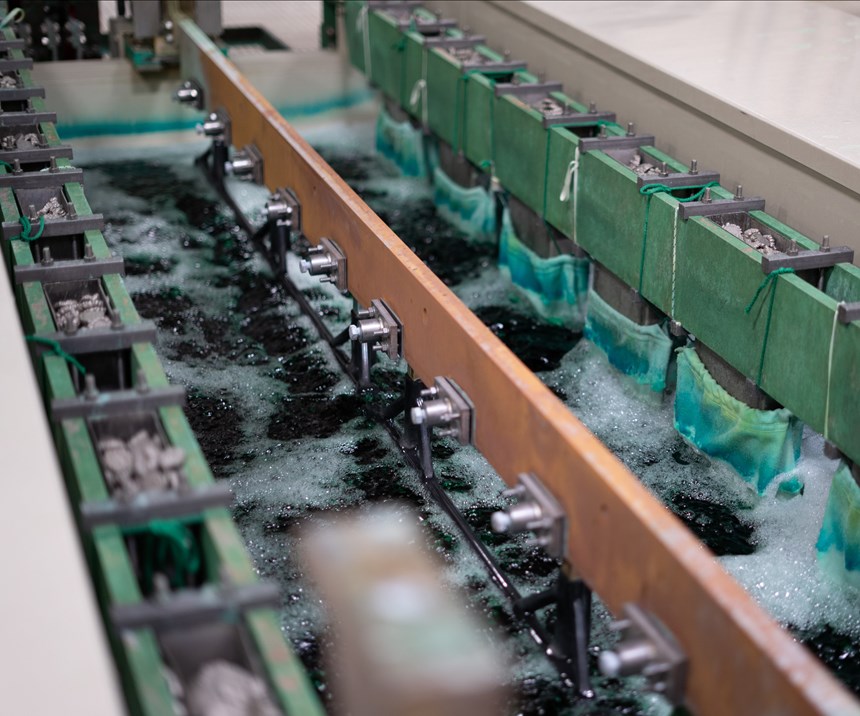

The Bolta U.S. plating line is roughly 550 feet. Atotech was responsible for building and installing all of the tanks, hoists and filtration systems, as well as providing the plating chemistry to meet the automotive specifications of Bolta’s customers.

Atotech’s Adhemax is used in the pretreatment process, which starts with an etching and neutralization, followed by an activation and acceleration before the electroless nickel plate is added as the conductive layer. Bolta is using the Cupracid series for the copper plating process, Unibrite for bright nickel and Satilume for the satin finishes.

By combining the line construction with the chemistry, Atotech feels they have an advantage for their customers because they can help them attain a very high yield and throughput, while often having very low downtime.

“When we walked out, it was a turnkey line,” King says. “Being a preferred supplier, when it comes to PoP, gives us the advantage of being a ‘one-stop shop’ for many manufacturers. We can engineer, design and build the line, and that helps when you want to go from a 90% yield to 95%. And every percentage after that makes a huge difference.”

Zero to Hundreds of Flight Bars

Once it was launched, the team worked with the plating line managers to get the system humming. As the facility is a greenfield operation with new personnel, it took some time to get the processes in tune with Bolta’s expectations before running at full speed.

“We went from zero flight bars to hundreds in what seemed like a day,” Gula says. “The challenges were there, but now we are in great position to really start attracting more work.”

Its property in Tuscaloosa is expansive, so Bolta has a growing plan in mind. That will be up to Gula and his team in business development to bring in new partnerships in the growing southeast U.S. automotive manufacturing sector. Mazda and Toyota recently announced partnership plans for a new $1.6 billion facility in northern Alabama that will be producing 300,000 vehicles by 2021. The new plant will produce the next-generation Toyota Corolla and a new Mazda crossover model.

In addition, Mercedes is spending $1 billion on its Alabama plant to set up electric vehicle production and build a battery plant, and another $500 million on its Sprinter van plant in Charleston, South Carolina. Volvo also opened a $500-million assembly plant in South Carolina.

Overall, Alabama is the U.S.’s fifth largest auto-producing state with more than 1 million vehicles built each year, a number expected to climb once the new plants reach full production.

“The south is really becoming the new Detroit,” Pechtold says.

Visit bolta.com and atotech.com.

RELATED CONTENT

-

Plating Q&A: Can you color stainless steel?

Our expert, Art Kushner, says yes, you can color stainless steel, but it is not a process that is typically performed in a plating shop. Read more about his answer.

-

Sizing Heating and Cooling Coils

Why is it important for you to know this?

-

Gold and Silver Plating Basics

An overview of precious metal electroplating processes.