Powder Application Methods Offer Variety And Versatility

Introduction Concurrent with the technological advancements made in the formulation of powder coatings are new and innovative ways to apply the powder and improve powder application efficiency.

Introduction

Concurrent with the technological advancements made in the formulation of powder coatings are new and innovative ways to apply the powder and improve powder application efficiency. Reviewed in this article are the latest advancements in powder application.

Color Changes

Recent and ongoing developments in the equipment used for powder application have significantly reduced the time, effort and capital cost required for color changes. Efforts to increase application efficiency, streamline the powder delivery system and redesign the booth have all contributed to speeding up the color change process. Properly designed, operated and maintained powder systems can change colors in minutes. Powder booths with plastic walls that repel rather than attract the powder, curved booth walls to discourage powder accumulation, automated belts and sweepers that brush powder particles on the floor to recovery systems, and powerful bursts of air through the pumps and guns to clean the system have helped reduce color change operations, sometimes to 10 minutes or less. Some high-production powder systems apply dozens of colors, with up to 20 color changes per day.

Featured Content

Coil Coating

Coil coating technology for powder continues to be developed. Coil coating is the coating on one or both sides of flat metal sheets or strips on a continuous production line basis, which are then cut and post-formed. Coil coating with powder can produce deep textures in a single pass, and unique visual effects not possible with liquid coil coating. It is used for a variety of products, such as appliances, lighting fixtures, window and door frames, solar sun screens and other building components.

Blank Coating

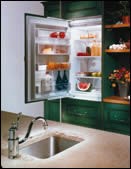

Powder coating of pre-cut metal blanks, which are then post-formed prior to final assembly, remains a strong growth area, particularly in the appliance market. This process allows for complete edge wrap, uniform film thickness and high transfer efficiency as blanks can be spaced only inches apart on the coating line.

Radiation Curing

Radiation curing is the curing of a coating by means of exposure to electromagnetic waves or particles such as infrared, ultraviolet, or electron beam. Radiation curing opens up new applications for the powder coating of heat-sensitive substrates such as wood, wood-based materials, plastic parts, and assembled components with heat-sensitive details by reducing the curing temperature to less than 250 F. The coating of metal substrates can also benefit from this technology, with lower energy and investment costs, shorter curing times and higher line speeds in powder coil coating plants.

IR Curing

Infrared ovens use radiant energy to cure the powder on the part, sometimes in as little as 30 seconds. The high heating rates possible in an infrared oven allow the surface to be heated without heating the entire substrate, providing a rapid heat-up and quick cool-down.

Ultraviolet Curing

Using specially formulated powders, curing by ultraviolet light is achievable. The powder needs to be exposed to enough heat so it is molten when exposed to ultraviolet energy. The heat source is typically infrared, but convection heating can also be used. The coating is then exposed to a lamp that directs UV light onto the product. The photoinitators–part of the coating–absorb the UV energy from the ultraviolet light source and initiate a series of chemical reactions that rapidly convert the molten film to a solid cured finish in a matter of seconds.

Near Infrared Curing

Newly developed near-infrared curing technology uses specially formulated powders, high-energy light sources and high focusing reflector systems, completing the powder coating and curing process within several seconds. Heat-sensitive assembled parts such as internal gaskets, hydraulic cylinders and air bag canisters can benefit from near-infrared curing. This process also allows swift curing times on metal substrates with no film thickness limitations, especially with colors like yellow or red that are difficult to cure in higher film thicknesses with current UV-powder coatings.

Electro-Magnetic Brush Technology

A new application process called electro-magnetic brush technology makes it possible to apply powder coatings at differential speeds and layer thicknesses on flat substrates. This process is similar to that used in photocopiers and laser printers, with “toner” particles triboelectrically charged against the ferromagnetic “carrier” particles, and transported with mixing rollers to a rotating shell or drum, which has stationary magnets within it. The ferromagnetic particles form a chain as directed by the magnetic field lines, also called a magnetic brush. The substrate becomes powder coated as it passes by the magnetic brush and the electrostatic field is turned on. Thicker layers can be achieved by passing the substrate by the magnetic brush more than once. Potential application areas include the coating of coil, blanks and even wood.

In-Mold Coating

An in-mold powder coating process has been developed in which powder coating material is sprayed onto a heated mold cavity before the molding cycle begins. During the molding operation, the powder coating chemically bonds to the molding compound and produces a product with a coating that is chip and impact resistant.

In-The-Field Powder Coating

Thermoplastic powders can be applied in the field, provided the substrate is clean and pre-heated properly. Bridge support columns and steel sidewalks have been coated successfully. Also pipe joints coated in the shop have been shipped to the field, welded together, and followed by the application of flamespray powder to the weld seams and pipe joints, creating a seamlessly coated pipe that is corrosion resistant.

Combining Technologies

Some finishing operations have developed ways to use powder coating in tandem with liquid finishing lines, using powder basecoats and liquid topcoats, for instance. This combined technology not only provides a more environmentally compliant finishing process than is achievable with a liquid-only finishing operation, but can result in new colors or effects not available in liquid or powder alone.

Robotics

Advances in microprocessors and robotics are also allowing increased production in powder coating facilities. Robots are typically used where an operation must be repeated for each workpiece on the line. The clearcoat being applied to BMW automotive body panels benefits from a complex series of twists and bends of a robotic gun, programmed to even shut the car door during the clearcoat application. When combined with analog powder output and voltage controls, robots can adjust powder delivery settings in the midst of coating a part, maneuvers too difficult to be accomplished manually.

Other Innovations

Application equipment manufacturers are also working to develop equipment that will deliver lower film builds to increase yields, increase first pass transfer efficiency, and further automate the powder coating application process.

Some companies monitor and control their powder coating operations by a modem linked to a remote computer. On-line process monitoring for automatic control of powder coating lines will become more important in years to come.

All of these advances, plus the inherent advantages of working with powder, ensure that powder coatings will have a permanent and ever-increasing share of the industrial finishing market.

RELATED CONTENT

-

Proper Testing of a Powder Coat Finish

Manufacturer shows how it performs extensive tests on powder coated medical carts.

-

Calculating Oven Heat Load Capacity

Please explain how to calculate the heat load capacity of a paint baking oven, using aluminum alloy wheels as an example.

-

Anodizing Vs. Powder Coat

I am an engineer on a large yacht build project and urgently need information and advice on choosing a finish for the aluminum deck plates in the engine room.