The hotbed of research in the coatings world is also probably one of the coldest places on earth: Fargo, North Dakota has an average low of -2˚ during January, and then zooms all the way up to 5˚ in February.

Temperatures aside, what goes on behind the classroom walls of North Dakota State University’s Department of Coatings and Polymeric Materials helps shape the paint and finishing industry with breakthrough research and sophisticated testing.

And in a worldwide industry with more than $50 billion in global sales – including the auto, furniture, appliance, medical device and other industries – that’s nothing to sneeze at, even though coming to NDSU may increase a student’s chances of catching a cold.

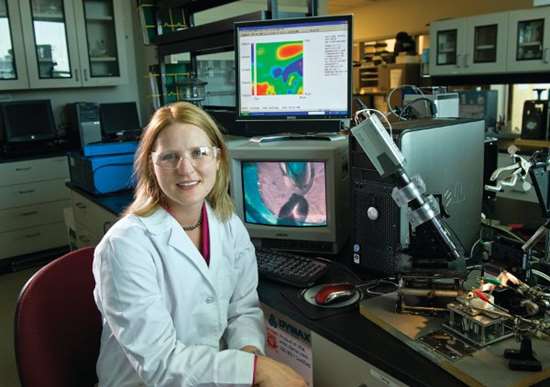

“The demand for coating and polymer expertise exceeds the supply,” says Dr. Victoria Johnston Gelling, an assistant professor in the NDSU department. “Our graduates are especially sought after by the coatings and chemical industries.”

SCOPING NEW HIRES

Employers such as 3M, Valspar, Bobcat, DuPont and Caterpillar routinely drop into Gelling’s and others classrooms at NDSU, scoping out a new hire to develop the next top coating compound or new corrosion-resistant material.

Says Gelling: “I’ve never heard of a student leaving here and not having a job in the industry.”

But this is nothing new for NDSU, which started offering coatings courses in 1906, the first university in the world to do so. The university claims its coatings and polymeric materials department is the only formal one in the United States, and its faculty and students interact frequently with leading companies and universities around the world.

“Coating science remains a fertile and interesting field because many modern inventions require protection, appearance or a special function provided by coatings,” says Professor Stuart Croll, chairman of the coatings department. “Even nano-materials are often deployed as a coating.”

The 30 students enrolled in the graduate program come from Asia, Europe, Australia, and South and Central Americas, as well as from the U.S. The university also offers a minor degree in coatings.

“We mainly focus on the masters and PhD level,” Gelling says. “This allows many of the students numerous research opportunities, but we also offer the minor option to any student here.”

Neil Thomas of Wahpeton, ND graduated in mechanical engineering with the coatings minor, and quickly had a job offer with 3M Company.

“There were 100 applicants from around the nation for this job, and mine was the only one with a Coatings and Polymeric Materials option,” Thomas says. “So I was the first and the last to be interviewed.”

WHO’S WHO OF COATING

That may be because NDSU has assembled a ‘who’s who’ of the coating world as an industry advisory panel: 3M, Valspar, Cytec, Rohm and Haas, Toyota, Akzo, Bayer, BASF, Sherwin-Williams, PPG, Phoenix, Tecton, Air Products, Boeing and the U.S. Air Force, among others, many of whom fund the program through individual scholarships for students.

Each fall the advisors travel to Fargo and meet with the NDSU faculty and students to get updates on research and to interact.

“Probably the most important component of all of this is that at the end of the sessions, the industry people tell the staff and the students what we need to focus on,” Gelling said. “Basically, they tell us what they will be needing in graduates, so the benefit is the industry is telling us how we should be educating our students so they are ready to leave here and get a job.”

All of this leads to connections for its students, as well as a steady pipeline of research funds. More companies are utilizing NDSU students and labs like it across the country to conduct studies on what might be the next breakthrough in coatings technology.

For example, Gelling leads a team of 11 graduate research students focusing on the use of electrochemical techniques for the study of materials and corrosion. A quick look at their current projects show that they have more than $1.8 million in grants from the U.S. Army Research Labs’ Aberdeen Proving Grounds, more than $46,000 in funding from the U.S. Navy, $75,000 in grants from PPG, about $60,000 from Marvin Windows, and $50,000 from Toyota. That’s on top of close to $3 million in completed research grants they has been obtained in the past seven years.

APPLIED RESEARCH

“The research we do tends to be very applied,” Gelling says. “We do a very good job in industrial research and getting that funding, plus our students get that real-life experience.”

The NDSU coatings faculty consists of eight professors, five postdoctoral researchers and 30 graduate students, as well as the undergraduates. NDSU recently opened a “Center of Excellence for Surface Protection,” where it offers companies the chance to partner with the school in research and testing. Among its functions are creating and testing application methods, performing studies in corrosion control and detection, accelerated exposure tests, and to provide technical consulting services for research partners and collaborators.

“About half of our graduate students have a deep chemistry background, and the rest have an engineering background,” says Gelling. “Coatings is a multi-disciplinary area, and if you look at our faculty you’ll find backgrounds in electrochemistry, physics, polymers and all varieties of areas that lend itself well to the department.”

The NDSU faculty and staff have published several hundred papers on coatings and polymers. Led by Croll and Gelling, the faculty also includes Professor Gordon Bierwagen, who teaches many of the corrosion courses after a lengthy career with Sherwin-Williams; Professor Erik Hobbie, whose research is on nanoparticle-polymer interactions in soft matter and biology; Professor Dean Webster, who helps carry out research in the synthesis and characterization of novel polymers; and Assistant Professor Andriy Voronov, who received his doctoral degree at Lviv Polytechnical Institute, Ukraine, and has conducted research in France and Germany.

IN-HOUSE TESTING

That expertise has led some companies to use NDSU as their ‘in-house” testing lab.

Technology Applications Group (Grand Forks, ND) needed testing done on a coating used on metal equipment and parts that must withstand demanding and extreme environments, and so they turned to NDSU’s CESP for assistance.

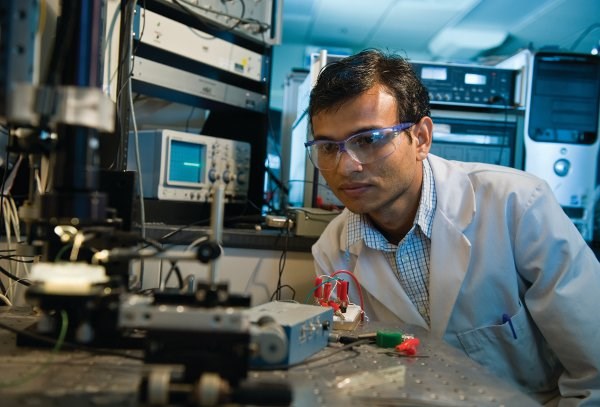

The lab’s specialized equipment allowed weathering to occur in a compressed amount of time using a salt fog chamber for accelerated, corrosive atmospheric testing. NDSU researchers also used electrochemical impedance spectroscopy to characterize the protective properties of the anodic coating.

“CESP and the NDSU Department of Coatings and Polymeric Materials are acknowledged experts in the field of coatings,” says Bill Elmquist, president of TAG. “The scientists and state-of-the-art instrumentation provide an impartial third party testing and analysis of our coatings performance.”

But NDSU isn’t judge for those trying to get their doctorate in coatings. They also offer summer short courses in coatings science, allowing professionals already in the field to broaden and deepen their understanding of coatings. Two courses are being offered in summer 2011 are ‘Corrosion Protection by Coatings: Testing and Lifetime Prediction’ (June 8-10) and ‘Fundamentals of Coatings Science’ (June 12-17).

ECONOMIC DEPENDENCE

“A lot depends on the economy, but we can get anywhere from 10 to 40 students from industry,” Gelling said. “Some courses we limit to 10 students because they has a laboratory component to it, and it’s hard to have too many students in the lab.”

By looking at the published research being conducted by the graduate students, it is obvious that the NDSU programs draw heavily from China and India to get its students.

“There’s no question that most of our students are international,” Gelling says. “It certainly seems that more people know about us in China and India that even in our own backyard.

For more information on North Dakota State University’s Department of Coatings and Polymeric Materials, please call 701-231-7633 or visit cpm.ndsu.nodak.edu

LEARN MORE

Back to School

Read about the University of Northern Iowa’s Spray Technique Analysis & Research (STAR) program at pfonline.com/articles/back-to-school

RELATED CONTENT

-

Masking is employed in most any metal finishing operation where only a specifically defined area of the surface of a part must be exposed to a process. Conversely, masking may be employed on a surface where treatment is either not required or must be avoided. This article covers the many aspects of masking for metal finishing, including applications, methods and the various types of masking employed.

-

Simply heating up the substrate does not cure the coating. There are many variables to consider when choosing the best cure oven for your application...

-

Is your metal finishing software ready for an upgrade?