Sustainable Pretreatment with Atmospheric Pressure Plasma

Alternative methods provide longer and stronger adhesion of coatings.

#sustainability

When it comes to achieving safe and stable adhesion of coatings and bondings on aircraft parts made of plastic, metal and composite, atmospheric pressure plasma has become the green and cost-saving pretreatment alternative to conventional methods.

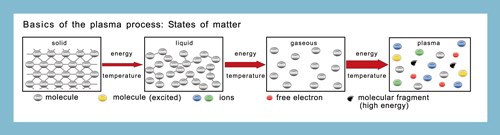

Plasma is based on a simple physical principle that, by supplying energy, states of matter change from solid to liquid and liquid to gas. If further energy is added to a gas, it becomes ionized—the electrons gain kinetic energy and leave their atomic shells.

Featured Content

Thus, free electrons, ions and molecular fragments are formed, and the gas turns into a plasma state which is also known as the “4th state of matter.” Because of its instability, however, this state could hardly be used in industrial production at normal pressure.

Twenty years ago, German plasma system manufacturer Plasmatreat developed an atmospheric pressure plasma jet technology called Openair-Plasma that opened up new possibilities for surface pretreatment.

With the invention of plasma nozzles, it was possible to integrate in-line an almost never used state of matter for industrial production processes, and make plasma usable for large-scale pretreatment of material surfaces under normal atmosphere. Now this technology is used in virtually all industrial sectors worldwide.

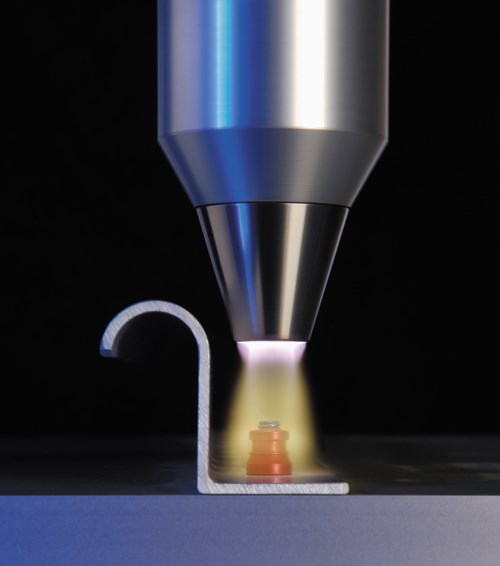

Reinforcing and fastening devices as well as countersunk riveted assembly parts are often difficult to clean. Plasma can not only eliminate the use of the primer, it can also accommodate complex geometries. Photos courtesy of Plasmatreat

Green, Fast and Secure

The atmospheric plasma jet process is characterized by a threefold simultaneous action: It strongly activates a surface by selective oxidation processes, eliminates static charge and brings about microfine cleaning. This results in a long-time stable adhesion of paints and adhesives, as well as an immaculate coating appearance due to enhanced surface wettability.

Trials at Plasmatreat have demonstrated that surface energy values of more than 72 dyne ((mJ/m²) are achievable when pretreating plastic materials. The result: Not only can previously incompatible substrates be bonded, water-based adhesive or paint systems can be adhered to very adhesive-resistant surfaces. The system can be implemented into new or existing production lines and is compatible without restriction with robots. The process is secure, reproducible, and the plasma beam is always locally selective.

In addition, this pretreatment method is cost-effective and environmentally safe because the nozzles are operated solely by air and electricity; no toxic emissions or waste materials are produced, and in most cases the use of solvents can be dispensed with altogether. The dry, contactless plasma treatment enables materials to undergo further processing immediately.

One special feature of the Openair-Plasma process is that the emergent plasma beam is electrically neutral, which greatly extends and simplifies the range of possible applications, especially when electronics are involved.

Its intensity is so high that when using individual stationary nozzles, processing speeds of several hundred meters per minute can be achieved. The plasma beam is formed and focused at the jet outlet and gives up its energy on contact with a surface. Depending on the power of the plasma jet, a single plasma beam can be up to 50 mm long and have a treatment width of 25 mm. The plasma source is moved at a distance of 10 to 40 mm from the surface and at a speed of 6 to 600 m/min relative to the surface of the material being treated, depending on the treatment power required.

Apart from the single jets, whole rotary systems are also available for pretreating relatively large surface areas. Depending on the application, they contain a number of plasma nozzles that rotate at very high speed. And depending on the diameter and arrangement of the plasma jets areas—such as lightweight composite panels—up to 3,000 mm wide can be treated in a single pass. Plastic surfaces heat to generally ΔT < 30°C during treatment.

Plasma Polymerization

For decades, it has been possible to apply functional plasma coatings on an industrial scale using low-pressure plasmas in a vacuum chamber—but never under normal air conditions. In recent years, Plasmatreat, working in close partnership with the Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM) in Germany, has developed and patented a further process based on the Openair technology known as PlasmaPlus, the world’s first industrial atmospheric pressure plasma coating process.

Concealed inside the plasma nozzles is an ingenious coating system that enables locally selective layer deposition to modify the functional characteristics of surfaces in a targeted manner. A precursor is added to the plasma to produce a coating. High-energy excitation within the plasma fragments this chemical compound and deposits it on the surface in the form of an ultra-thin vitreous coating.

Essential to the user is the fact that he or she can vary both precursor and plasma performance to define layer functionality. By adjusting the plasma parameters and nozzle geometry, a user can selectively control the layer chemistry.

Applications in Aerospace

The aerospace industry is committed to developing and adopting technologies that reduce its environmental impact. The Openair-Plasma process is currently undergoing intensive testing in the aircraft engineering industry for surface preparation of aluminum and composite aircraft parts and structures for painting and coating.

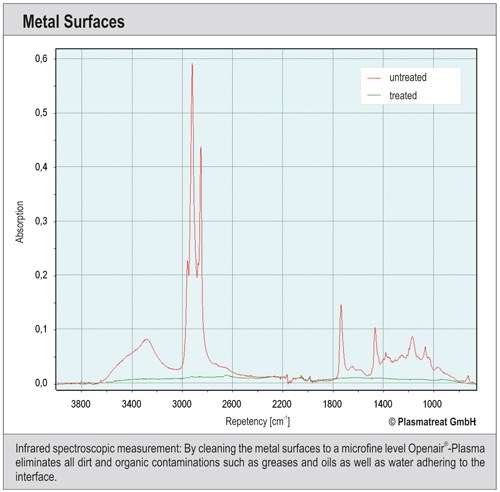

The system is suitable for rapid treatment of both large-area parts such as aircraft wings or fuselage components as well as small areas. In the course of fine cleaning of metal surfaces, Openair-Plasma removes all impurities and organic contaminants (such as grease and oils) as well as water adhering to the boundary layer. Because the primary parameters are proximity to the surface and treatment speed, the plasma jet can be robotically controlled to provide repeatable cleaning and surface activation. Thus, the variability and costs associated with hand sanding and media blasting can be eliminated.

Surface Preparation of Aluminum

The shiny, high-gloss paint on the commercial airlines is not just for visual appearance. The real purpose of aircraft paints and coatings is to protect the high-strength aluminum structure from the harsh environmental conditions that the aircraft will face over many years of service. The paint must protect the plane from corrosion due to moisture ingression and erosion due to rain, hail and runway debris. At the same time, the trend to high-performance composites in aircraft presents new challenges for pretreatment and painting.

Surface preparation of the aluminum is the first step of a multi-step coating process of acid etches, conversion coats, primers and top coats—well-established processes governed by hundreds of specifications. Often, the first step involves solvent wash, media blasting or hand sanding, but there is increasing pressure to eliminate solvents, toxic materials and the variability of hand labor.

Atmospheric plasma not only eliminates these concerns, it also replaces environmentally detrimental or cost-intensive cleaning processes.

Plasma Instead of Primer

Anticorrosion primers are frequently used on interior parts of the aircraft fuselage, in wing structures with reinforcing and fastening devices, and in countersunk riveted assembly parts that are often difficult to clean and pretreat. Not only can atmospheric plasma eliminate use of the primer, it can also accommodate complex geometries.

Due to requirements for low weight, improved material fatigue characteristics and corrosion resistance, sophisticated composites are increasingly being used in aircrafts. These are layered materials usually produced in casting molds from plastic reinforced with carbon fibers and cured at relatively high temperatures. Starting with fiberglass composites in secondary components, such as payload claddings and covers, carbon fiber composites are used in main components such as aircraft wings, control elements and fuselage parts. These cast parts are contaminated by mold release agents, which frequently contain silicones. In order to ensure reliable painting, these contaminants must be removed completely.

Safe for Mixed Materials

The plasma process is suitable for the surface preparation of mixed materials—both carbon composites and metals can be treated without the electrical arcing that comes with methods such as corona treatment.

But not all aircraft components require the application of paint or liquid coatings. Many interior surfaces such as bulkheads, luggage bins, walls and ceilings are finished by laminating easy-to-clean plastic foils to the composite parts, and atmospheric plasma can also be used to increase laminate adhesion. The decisive advantages of using Openair atmospheric plasma technology include its reliability and quality in the production process, thereby meeting the stringent requirements of aircraft manufacturers. On top of that, users benefit from simple process integration, higher economic efficiency and environmental friendliness.

Inès Melamies is a journalist and Wally Hansen is a key account manager for Plasmatreat. For more information, please call 650-596-1606 or visit plasmatreat.com

RELATED CONTENT

-

Is Your Electroplating Waste Hazardous?

Some that bears precious metals is, and there are a host of regulations to consider when recycling.

-

Pretreatments: The Next Generation

Emerging technologies can save energy, ease environmental concerns

-

Cleaning and Corrosion Protection with Solvents

Protect parts against rust in efficient, sustainable way.