System Synergy

Robot, programming, hardware and materials developments boost automotive finishing

#automotive

Advances in automotive finishing over the last decade have come from nearly every part of the process, including robots, programming, application hardware and paint technology. Technical developments include explosion-proof robots with improved kinematics and acceleration, electrostatic high-speed rotary bell atomizers and cartridge bell systems, waterborne paint materials and increasing use of powder coating in select applications.

Factors driving increased robot use in automotive applications include repeatable finish quality based on pre-programmed operations, high flexibility for vehicle model change, production of multiple vehicle models in the same line, and reduced safety and health hazards. Robots also provide increased productivity and better capital equipment utilization over longer periods of time and in multi-shift schedules, as well as more consistent use of consumables and energy in a more repeatable and controllable process.

Featured Content

One way robotic painting saves energy is by reducing spray booth ventilation requirements. Booth air can be recirculated up to 90% or more in some cases, generating considerable energy savings. Robots also need less total ventilation air; downdraft velocity in a robotic paint booth is roughly half that needed for conventional painting. Lower downdraft velocity facilitates use of electrostatic atomization methods, which have softer spray patterns and achieve better quality and efficiency at lower ventilation velocities.

Robot Developments

In the last few years, ABB Inc., Robotics has made several contributions to high-performance painting. These include process solutions that minimize non-painting time by keeping the paint atomizer in its optimal path. This process optimization supports high atomizer outputs, reliability, clean operation and minimal paint loss.

For robots, these new processes require very high speed and acceleration capability. The ABB IRB 5500 line of paint robots feature unique kinematics and rapid acceleration (26 m/sec2) that improves paint output and efficiency and allows spray booths to be narrower and shorter. These robots’ joint location, optimized length of arm segments and kinematics arrangement facilitate painting of the entire car body in a very compact spray booth. Benefits of this include elimination of the in-booth rail axis, which is not required due to the robots’ large work envelope and kinematics arrangement; and reduced booth size with the elimination of the rail and the seventh axis.

ABB IRB 5500 robots are typically installed at the booth wall and located at mid-height. This mounting position, along with the robot kinematics arrangement, allows the robot arms to move parallel to the car body surface. Mid-height mounting also provides easy access to robot maintenance areas.

Conventional seven-axis robots need booth widths of approximately 5.5 m, while the new robots can work in a booth 4.6 m wide. This makes them suitable for use in replacement of existing side- and top-machine booths. Reduced booth width decreases capital costs and energy consumption, resulting in lower overall operating costs. The units’ extreme longitudinal reach also allows elimination of the conventional longitudinal robot rail (seventh axis), simplifying installation and maintenance and reducing complexity of paint and compressed air connections.

Liquid Paint Application

Developments in other components of the application system are further inproving productivity. Electrostatic rotary bell atomizers, for example, provide high paint output, flexible spray pattern control for increased paint utilization efficiency, and very good finish quality. Another technology, the cartridge bell, minimizes paint losses and solvent consumption during color changes.

The atomizer is the heart of the painting process, impacting not only finish quality but also production capacity. Rotary bell electrostatic atomizers have become the state of the art for automotive applications. They allow highly uniform film builds by means of their high-speed bell cup rotation and low paint consumption by electrostatic attraction of charged paint droplets to the coated substrate.

ABB’s IRB1000 rotary bell atomizer was designed to double the capacity of current atomizer technology. Powerful air turbines can handle high paint flow rates while rotating at high speed. The main benefits of the technology include:

- Paint flow rates approaching 1,000 cc/min

- Reduced overspray with pattern size control

- Fine atomization with rotation speed up to 70,000 rpm

- No air heater even at higher turbine speeds.

The unit is applicable for both waterborne and solvent-borne paints, and its compact design allows use on both interior and exterior car body applications. The number of atomizers required to coat a car body is tightly connected to the atomizing capacity of each atomizer, that is, the volume of paint per minute each atomizer can spray. Higher-capacity atomizers translate into fewer atomizers, thus, fewer robots, smaller spray booths and a more compact and flexible paint line.

Cartridge bells are based on the simple concept of bringing paint as close as possible to the application to allow color changes with minimal paint loss. This is accomplished by replacing paint supply tubes with cartridges that contain the proper amount of paint for one car. These cartridges feed the atomizer, eliminating the need for a paint line to supply the atomizer. Elimination of the paint line facilitated implementation of the insulation needed for high-voltage application of water borne paint. ABB ’s cartridge bell system has other major benefits as well, including fast color changes with near-zero paint loss.

Cartridge cleaning and filling stations are mounted on the booth wall. The cartridge works like a syringe with a “needle” (feed tube) that injects the paint just at the bell cup level; paint is never loaded in the atomizer. During a color change cycle, the bell cup is cleaned and the cartridge is changed. A servomotor-driven system controls paint dosing, and overall system control is integrated around a single robot controller.

Originally designed for a reduced number of colors using dedicated cartridges for each color, the cartridge bell system is now often used in lines that spray many more colors. This is enabled by development of flushable cartridges, which helped evolve the system into a flexible solution that combines use of both dedicated and flushable cartridges depending on the color.

Process Improvements

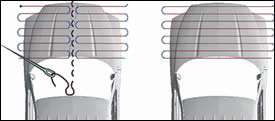

Robotic painting operations are further improved by programming techniques that take advantage of the capabilities of state-of-the-art robot and application systems. These include NoPatch, which eliminates the “patchwork” required when panels are painted in small sections with multiple robots; and StayOn, which keeps the atomizer on the area to be painted to reduce overspray and cycle time.

Merging robot paths in the center of body panels became an accepted practice some time ago because older robots did not have the reach and work envelope to allow programmers to do otherwise. The merging areas have always been a weakness of robotic paint application and a potential source of quality defects.

NoPatch programming eliminates patchwork by painting with strokes that cover the full length of every panel. It also reduces paint cycle time. Time during the paint cycle can be divided into two types: time used for painting and time used to reposition the atomizer between painting strokes. Painting large body panels in many small sections increases the amount of repositioning needed.

For example, painting an automotive hood using two robots located on each side of the car takes 13.2 sec for each robot—total cycle time of 26.4 sec. Using identical application parameters and painting with only one robot from either side will take 22.8 sec.

A further improvement of the process, called StayOn, reduces cycle time, paint overspray loss and material consumption during the painting cycle. It takes advantage of the high acceleration capability of our company’s robots.

Typical robotic paint processes are based on parallel passes with an indexing step between each pass. Indexing is normally done outside the painted area because robots must slow down while making the index and reversing direction, thus dropping a larger amount of paint in the indexing area.

Robots with rapid acceleration capability, however, do not slow down in the corners and keep their speed fairly constant even in turns. They may even be required to move faster in some areas. Cycle time is greatly reduced, the robot travels a shorter total distance and nearly the entire cycle becomes painting time. Overspray and paint usage are also reduced because the atomizer never leaves the area being painted.

Powder Coating Developments

Due to their favorable environmental properties, powder coatings are increasing in application faster than liquid paints. However, these gains have been largely limited to functional coatings. For a variety of reasons, adoption of powder application in high-quality and appearance decorative clear and multiple-color coatings has been much less pronounced and has been slower than expected.

In the automotive industry, powder coating has found its niches. Single-color powder primer surfacers are standard solutions for GM and Daimler Chrysler. Primer surfacers in multiple colors have been introduced in newer GM and Chrysler plants in the U.S. and in two Peugeot-Citroen plants in Europe. BMW in Germany and Harley-Davidson in the U.S. have been using powder clear coats for more than 10 years. Multi-color base coat powders, including special effect materials and metallic base coats, have been tested during the last few years and are expected to be implemented in the near future.

However, automotive powder coating materials still require development to improve clear-coat robustness, provide a wider variety of colors for prime and topcoat applications, and reduce particle size for lower film builds and improved film build uniformity. Other challenges include the need to increase transfer efficiency to reduce contamination risks due to reclaim, development of fast color change systems in dense flow and improvement of robustness with respect to application, process control and material handling.

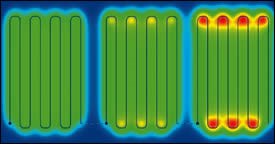

To meet these requirements, ABB Inc., Robotics has developed several equipment and process advances, which are aimed to promote the enhanced efficiency, performance and flexibility of robotic powder coatings. These include processes capable of applying thin-film powder coatings with high uniformity; high-transfer-efficiency powder application equipment, including an internal charging (IC) spray gun; a compact and fast powder color change system and equipment; and dense-flow powder dispensing technology and color change for softer handling of powder paint material and improved coating quality.

ABB’s patented IC powder gun is an electrostatic gun designed for application with robots and reciprocators. It was developed to provide high transfer efficiency at powder flow rates from 100-1,000 g/min and high transfer efficiencies. The gun provides a well-defined external electrostatic field and improved attraction of powder toward the substrate to improve transfer efficiency and film build uniformity even at variable powder flow rates and spraying distances.

Spray patterns are variable using a wide selection of flat nozzles and round patterns controlled by tangential shaping air without mechanical deflectors. The gun supports high output rates and applicator tip speeds of up to 40 inches/sec (1 m/sec) required for robotic applications. An internal ground electrode reduces free ions and back ionization risks by filtering any free ions.

For color changes, ABB developed a system to support multi-color powder paint application lines with typical color change times of 10-15 seconds—similar to those of liquid paint systems. Typical automotive applications for such systems include color-key and color-specific primer surfacer systems.

The system collects mixed-color powder overspray for use in other coatings that do not demand the same high color standards either in the same plant or elsewhere. Optimal application of the proposed system will require use of a powder applicator with high primary transfer efficiency, such as an IC gun, to reduce the amount mixed color overspray and improve total system efficiency.

A recent development in powder coating is the introduction of so-called dense-flow pumps, which address issues of friction on powder particles and abrasion of application components. These problems often result in coating defects and reduced total coating quality. Another factor in development of dense-flow powder dispensing is the need for higher powder flows—roughly 600 g/min, compared with conventional requirements of 200 g/min.

Dense-flow pumps use a variety of operating principles to enable delivery of powder concentrations 10× higher than conventional pumps. These include Digital Dense Flow, which is based on a two-piston pneumatic reciprocating pump; and High-Density, Low Air Volume, which uses an alternating vacuum/pressure principle for suction and expulsion of powder to and from small chambers made of porous filter material. Other pumps use small (up to 1 gal) pressurized fluidized beds—so-called pressure pots—to feed powder at dense flows. ABB pioneered in some of these developments, resulting in two early patents in the mid-1990s.

RELATED CONTENT

-

Understanding Paint Atomization

BASF coatings development expert Tim December explains how paint atomization works for both pneumatic spray applicators and high-speed rotary bell applicators.

-

Is Your Electroplating Waste Hazardous?

Some that bears precious metals is, and there are a host of regulations to consider when recycling.

-

Zinc Phosphate: Questions and Answers

Our experts share specific questions about zinc phosphate and pretreatment