The Challenge of Electroplating Cast Iron Components

Manufacturing from cast materials is a cost-effective method to form complex shaped components.

By Rainer Paulsen, Enthone Inc.

Featured Content

Manufacturing from cast materials is a cost-effective method to form complex shaped components. It affords greater versatility in component design, while also offering excellent machinability, good strength-to-weight ratio, and heat treatment is not necessary for most applications.

However, surface finishing can present a challenge, due to the properties of the cast material that includes high carbon content often enriched at the surface, impurities such as silicon or sulfur, and rough, non-homogeneous surfaces.

Therefore, the selection of a suitable pretreatment prior to metal deposition—as well as knowledge of the processes during the metal deposition—is essential to achieving a durable and reliable finished component.

Pretreatment of Cast Iron

The most important step is the physical/chemical pretreatment for electroplating, which must be adapted to the type of cast material and the surface condition. A particular challenge for electroplating is the combination of high carbon content and molding sand residues on the surface. For this reason, a suitable alkaline cleaner in combination with ultrasonics is recommended as a first step to blast off carbon and sand residues.

Cast materials may be heavily oiled. The oils must be completely removed to prevent contamination in the subsequent process solutions. An alkaline emulsifying soak cleaner is highly recommended as a remover.

The acid pickling stage is particularly crucial. Strong pickling leads to carbon enrichment at the surface, which can interfere with electroplating initiation of the metallic coating. Pickling times should be kept as short as possible. Inhibitors are optional, so one can find practical applications with or without inhibitors.

Heavily rusted components should be cleaned using either an alkaline process step or by mechanical means. If the de-rusting is done by use of an acid pickle, it must be verified that the coating in serial production will result in sufficient quality.

Fundamentals of Zinc Deposition on Cast Iron

In the electrochemical series, zinc has a standard electrode potential of -0.76 volts. The presumption is that deposition of zinc is not possible from a water-based solution. Only the more noble hydrogen would be released during electrolysis, not zinc. However, hydrogen overvoltage occurs during electroplating, and the hydrogen potential shifts to more negative value. This allows zinc deposition to take place with hydrogen evolution as a side reaction.

Standard electrode potentials listed in the electrochemical series are related to normalized composition of the electrolyte. Electrolytes used in the field show a totally different composition. Consequently, the standard electrode potentials listed in the electrochemical series should be viewed as a guide only. The practical deposition potentials are what are relevant. When steel is plated using a mild acid zinc electrolyte, the hydrogen overvoltage is about -0.7 volts for these electrolytes with a pH of approximately 5.2. Zinc is therefore effectively deposited without problems at >90% efficiency.

With cast iron, surface carbon reduces the hydrogen overvoltage, leading primarily to hydrogen evolution at the cast iron surface. Zinc deposition is delayed or suppressed; often it is only partially realized. In particular, sections of low current density initiation of zinc is inhibited, leading to poorly covered parts. As a result, incomplete deposition or uneven metal distribution occurs.

A weak acidic electrolyte is preferable for electroplating cast iron. The hydrogen overvoltage is -0.7 volts for these electrolytes with a pH of approximately 5.2. Zinc deposition occurs at an efficiency of >90%.

Cast Iron Coating Methods

In practical applications, three types of zinc-based processes are used:

• Pure Zinc from acidic or alkaline electrolytes

• ZnCo alloy with 0.6 - 1.2 % Co from acidic electrolytes

• ZnNi alloys with 10 - 16 % Ni from acidic or alkaline electrolytes

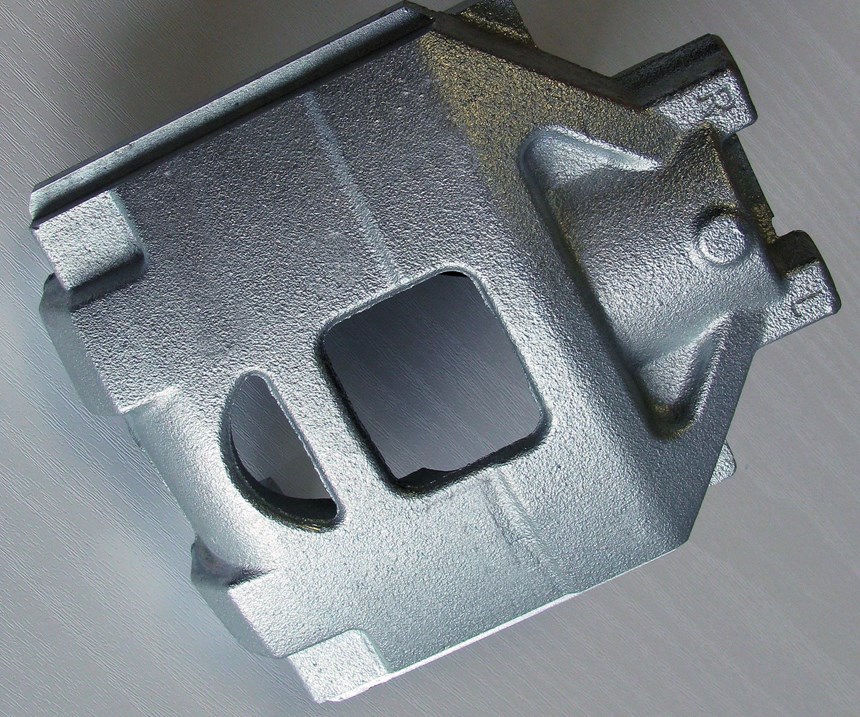

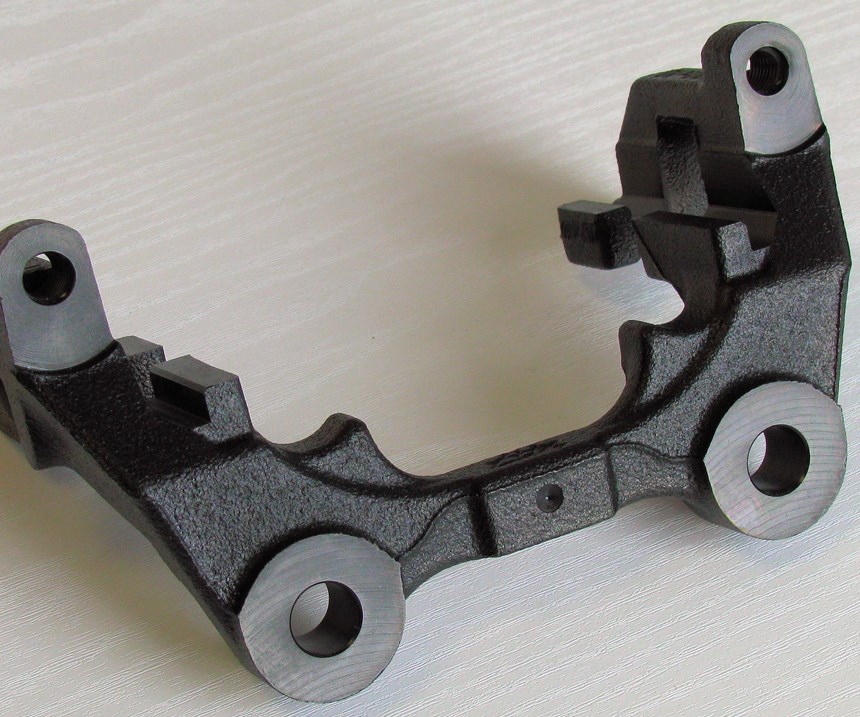

The brake component industry has the largest share of cast material for electroplating. Electroplating cast iron brake components from acidic zinc electrolytes is a well-established practice. Process optimization is critical for producing high volume and high quality zinc coatings. Parameters for running the process must be aligned to each other in order to reach optimal plating conditions. Key points for controlling the process are:

• Electrolyte with organic additives optimized for cast iron

• High chloride content to achieve conductivity and metal distribution

• Increased carrier agent content compared to electroplating of standard steel

• Low temperature, preferred <30°C

• Strong electrolyte agitation (air agitation or venturi nozzles)

• Good rack technology with an optimized arrangement and sufficient cross-sections to allow uniform current across the entire rack

ZnNi to Meet Demand for Corrosion Performance

New demands for extended corrosion protection and appearance are driving the growth of ZnNi in the brake industry.

Significant factors include the automotive industry’s abandonment of hexavalent chromium and increased use of aluminum. (ZnNi is an excellent choice to prevent contact corrosion with aluminum.)

The use of alkaline electrolytes is generally possible, but it leads to a delay during initial metal deposition and to incompletely coated components. This is more pronounced with ZnNi alloy electrolytes than with zinc. Direct coating of castings in alkaline ZnNi electrolytes is possible, but only with greater effort.

The initial phase requires an excessive current density of up to 10 A/dm2, which necessitates the installation of high voltage, large-scale rectification, strong electrolyte movement, high cooling power and specially designed racks and contacts. This triggers costs that make alkaline ZnNi deposition uneconomical. Consequently, this technology is only used for special applications.

Double coating is a viable alternative. It utilizes the proven technology of acidic electroplating to first deposit a homogeneous zinc coating on the entire work piece. After intensive rinsing, the required ZnNi coating is then electroplated from an alkaline ZnNi electrolyte. To ensure complete zinc plating of the surfaces, 15 - 25 minutes time is typically required. This corresponds to an average coating thickness of 10 - 12 µm Zn. The required coating of 8 - 12 µm ZnNi is then electroplated.

Due to the low efficiency of alkaline ZnNi electrolytes of about 50%, an additional 30 - 50 minutes are required to achieve proper ZnNi thickness. The component now has about twice the coating thickness, which not only increases costs, but there could be dimensional tolerance problems. Moreover, a major problem is potential failure in the temperature shock test (30 minutes exposure to 300°C, followed by quenching in water at 20°C). In many cases the ZnNi coating separates from the zinc coating.

Components manufactured from cast iron offer a practical solution for a variety of complex shaped parts. But unlike stamped or extruded ferrous components, particular attention must be exercised to assure a properly finished cast iron component. The selection of appropriate pretreatment prior to metal deposition plus the actual electroplating processes are essential steps for achieving a durable and reliable finished component. To meet the industry’s demand for improved durability and performance, the new generation of ammonium-free acid ZnNi provides the most economical and practical solution. Its performance and reliability are supported by its production proven use on brake components at major automotive manufacturers.

RELATED CONTENT

-

Stripping of Plated Finishes

The processes, chemicals and equipment, plus control and troubleshooting.

-

Plating Q&A: Can you color stainless steel?

Our expert, Art Kushner, says yes, you can color stainless steel, but it is not a process that is typically performed in a plating shop. Read more about his answer.

-

An Overview of Electroless Nickel Plating

By definition, electroless plating is metal deposition by a controlled chemical reaction.