The Importance of Powder Booth Filtration

Choosing a powder filter is a lot like buying new tires.

Choosing a powder filter is a lot like buying new tires. There’s a wide selection that will fit, but a lot of subtle differences in their performance, durability and price.

Choosing the least expensive filter that will fit your booth is like buying the least expensive tire for your car—it may not make sense. But what makes one filter a better value than another? In order to find the answer to that question you must ask, what exactly is the role of the filter?

Featured Content

The filter is more than just a stand-alone component. As part of the spray booth design, an improper filter will affect the overall performance and efficiency of your powder line.

Since powder booths need to contain the over-sprayed powder so it doesn’t spill into the plant, blowers are used to create a negative pressure inside the booth. Typically, the designed air velocity at the booth openings is around 100 – 120 feet per minute.

The large volume of air being pulled into the booth must be exhausted. But we don’t want to exhaust powder particles back into the room. This would cause a nuisance in the plant. And many operators reclaim their over-sprayed powder and will want to reclaim as much powder as possible. This means the air needs to be filtered as it escapes the collector leaving the powder behind to be reclaimed and re-sprayed.

Durability is important on systems that pulse the filters with positive air bursts (typically 40 to 60 pounds per square inch) to clean them. The repeated pulsing of the filter can prematurely wear inferior filters and reduce their useful lifetime.

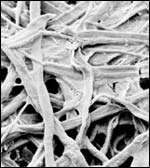

Like many air filters, powder filters are usually porous membranes with pore sizes small enough to trap all but the finest powder particles (in a well designed system these go to the final filter). Often the pore size ranges from 2 to 6 microns.

The most popular design of filter used in modern powder booths is a cylindrical cartridge ranging from 24” to 48” in length. It is typically constructed of filter media and wire or expanded metal for structurability. To increase the surface area and maximize the efficiency of the filter, the media is often pleated. Depending on the size of the powder booth there may be anywhere from 2 to 24 filters per booth.

Cartridge filter media is made of various materials including Cellulose, Polyester, and PTFE. Cellulose cartridges, or paper filters, are the least expensive and come in cellulose/polyester blends ranging from 80/20 to a heavy duty 60/40 mix. Spun polyester filters provide a host of benefits not attainable with cellulose but at a higher cost.

One popular measurement of a media’s efficiency is the air/cloth ratio, which might vary from as little as 2/1 to as much as 6/1. However, you should not place too much reliance on air/cloth figures when comparing media of different types since each media has it’s own efficiency and a 4/1 cellulose filter is not comparable to a 4/1 polyester filter of the same size and air rating.

A very tangible difference in filters is the amount of powder that is retained in the filter even with cleaning. It is common for cellulose filters to retain anywhere from 15 to as much as 40 pounds of powder. Testing on polyester filters, however, shows that they typically retain about three pounds of powder. A difference of say 30 pounds of powder at $2.50 a pound adds $75 to the cost of the filter. Multiply this by 15 or 20 filters on the line and you may have thousands of dollars in wasted powder being thrown away with the filters.

A powder-laden filter is not only a more costly filter it also creates a large pressure drop, which causes problems with maintaining proper airflow.

Like buying tires, the differences often require close examination of the construction. More high-tech filters use dimple construction to increase the efficiency and durability of the media.

Similarly, the size and spacing of the pleats on filters plays a role in their efficiency and also their cost. Deeper, close-spaced pleats (more pleats per filter) provide better filtration but typically cost more.

For example a standard 36” filter from the OEM may have 120 pleats and sell for $120. An aftermarket filter of the same size may cost only $95 but have only 90 pleats. The two filters are not identical and all things being equal, the 120-pleat design will operate more efficiently.

Durability is important on systems that pulse the filters with positive air bursts (typically 40 to 60 pounds per square inch delivered at intervals of around 90 seconds) to clean them. The repeated pulsing of the filter can prematurely wear inferior filters and reduce their useful lifetime. Spun bonded polyester filters can withstand over 100 pounds of pressure without damage.

Understanding how pleated filters behave under pulsed air has led to better designs.

A conventional pleated filter gets “pinched” at the top of each pleat as the filter loads with powder. This pinching reduces the overall surface area and limits the filter’s efficiency.

Another problem with the common saw-tooth pleated designs is that the pleats tend to “balloon” during pulsing. The distortion in this phase of use leads to trapped powder in the trough of each pleat. The dimpled design is free of trapped powder following pulsing and returns to its pre-pulse efficiency. Ballooning also appears to reduce the mechanical integrity of the filter and leads to cartridge failures.

In a controlled test comparing the lifetimes of cellulose and dimpled polyester cartridge designs, the dimpled design provides over four times that of simple paper cartridges.

In conclusion, your original system was most likely shipped with high quality filtration designed to work as a complete system with your powder booth. Eventually you will be faced with deciding what replacement filters to buy. With powder filters you usually get what you pay for. Simple pleated paper filters are the lowest cost choice but frequently cost more in the long run because they retain powder, reduce transfer efficiency and fail sooner than a more expensive filter. On a large system, the wrong decision can be more costly than many operators realize—choose wisely.

Nordson Corporation, Industrial Coating Systems

RELATED CONTENT

-

Touch-up Options for Powder Coated Parts

Is it true that powder coating cannot be touched up? Powder coating expert Rodger Talbert offers options for powder coating touch-ups.

-

Calculating the Cost of Powder Coating

How can you calculate the cost of powder coating a component if you only know its surface area? Powder coating expert Rodger Talbert has the answer.

-

Coating Systems with the Best Long-Term Performance

The best protection against corrosion and UV exposure, says Axalta’s Mike Withers, is electrocoat and a super durable powder coating.