A suite of tests developed by the National Institute of Standards and Technology (NIST) and three industry partners could eventually help your vehicle’s exterior better defend itself against dings, dents and scratches.

In a paper in the journal Progress in Organic Coatings, researchers at four organizations—NIST and industry partners Eastman Chemical Co., the Hyundai America Technical Center and Anton Paar USA—describe three versions of a fast, reliable laboratory method for simulating scratching processes on automobile clearcoats. The tests are designed to give manufacturers a better understanding of the mechanisms behind those processes so that future coating materials can be made more scratch resistant and resilient.

Featured Content

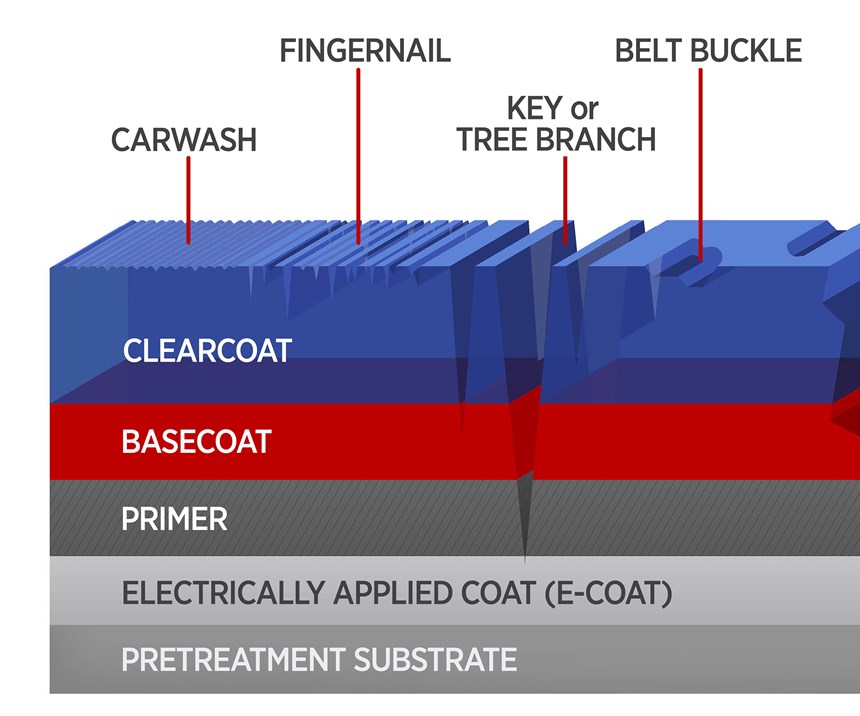

Currently, automobile coating manufacturers use two simple test methods to evaluate clearcoat scratch resistance and predict field performance: the crockmeter and the Amtech-Kistler car wash. The former is a device that uses a robotic ‘finger” moving back and forth with varying degrees of force to mimic damage from human contact and abrasive surfaces. The latter is a rotating wheel of brushes that simulate the impact of car washes on clearcoats.

“Unfortunately, both methods only assess clearcoat performance based on appearance, a qualitative measure where the results vary from test to test, and they don’t provide the quantitative data that scientifically helps us understand what happens to auto finishes in real life,” says NIST physicist Li Piin Sung, one of the authors of the new paper. “We demonstrated a test method that characterizes scratch mechanisms at the molecular level because that’s where the chemistry and physics happens … and where coatings can be engineered to be more resilient.”

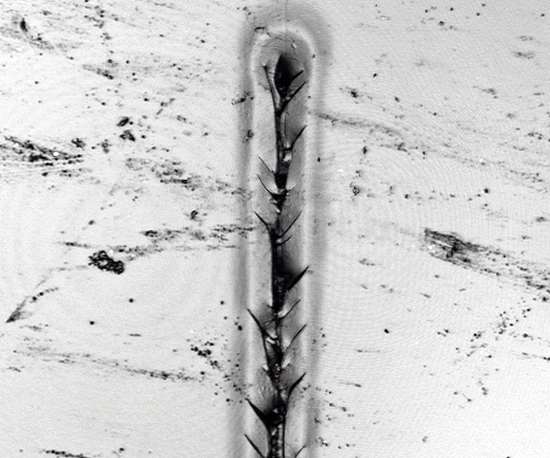

For their test method, the researchers first tapped a diamond-tipped stylus across the surface of a polymer composite sample to map its morphology, then used the stylus to create a scratch and finally, retapped and remapped the surface. Three different scales of scratch tests—nano, micro and macro—were conducted using different size tips and different ranges of force.

The quantitative differences between the pre-scratch and post-scratch profiles, along with microscopic analyses of the scratches, provided valuable data on vulnerability to deformation, fracture resistance and resilience.

NIST ran the nano-scratch test with a tip radius of 1 micrometer (a micrometer is a millionth of a meter, or about one-fifth the diameter of a strand of spider silk) and a force range between 0 and 30 micronewtons (a micronewton is a millionth of a newton, or about 20 millionths of a pound of force). Anton Parr did the micro-scratch test with a 50-micrometer tip and a force range between 25 micronewtons and 5 newtons (equivalent to 5 millionths of a pound to 1.25 pounds of force), while Eastman Chemical performed the macro-scratch test with a 200-micrometer tip and a force range between 0.5 and 30 newtons (equivalent to one-tenth of a pound to 7.5 pounds of force).

When scratches in the clearcoat are a few micrometers in depth and width, and occur without fracture, they are referred to as mars. These shallow, difficult-to-see deformations, Sung says, are most often the result of car washing. She explained that the nano-scratch test provided the best data on the mechanisms of marring and light scratches while the micro- and macro-scratch tests conducted were better at yielding detailed information about the larger, deeper and more visible deformations known as fracture scratches—the injuries caused by keys, tree branches, shopping carts and other solid objects.

“Data from the nano-scratch test also proved best for determining how well the coating responded to physical insult based on its crosslink density, the measure of how tightly the polymer components are bound together,” Sung said. “With this molecular-level understanding, clearcoat formulas can be improved so that they yield materials dense enough to be scratch resistant and resilient but not so hard that they cannot be worked with easily.”

The researchers concluded that to get the truest evaluation of clearcoat performance, the nano-, micro- and macro-scratch tests should be conducted in conjunction with the current industry standard methods. “That way, one gets the complete picture of an auto body coating, both qualitatively and quantitatively characterized, so that the tougher coatings created in the lab will work just as well on the road,” Sung said.

Paper: L. Feng, N. BenHamida, C-Y. Lu, L.P. Sung, P. Morel, A.T. Detwiler, J.M. Skelly, L.T. Baker and D. Bhattacharya. Fundamentals and characterizations of scratch resistance on automotive clearcoats. Progress in Organic Coatings. Published in December 2018 issue. DOI: 10.1016/j.porgcoat.2018.09.011

RELATED CONTENT

-

Quality Finishing: Don’t Starve Your Spray Gun for Air!

Tips to Avoid Pressure Drop in Air Spraying

-

Drivers of Change

Is your metal finishing software ready for an upgrade?

-

Painting Over Powder Coating

How safely can they apply their wet paint over our powder coated parts?