Bob Zimmerli considers himself a throwback in the powder coating business, one who still treasures the finer details of applying a finish.

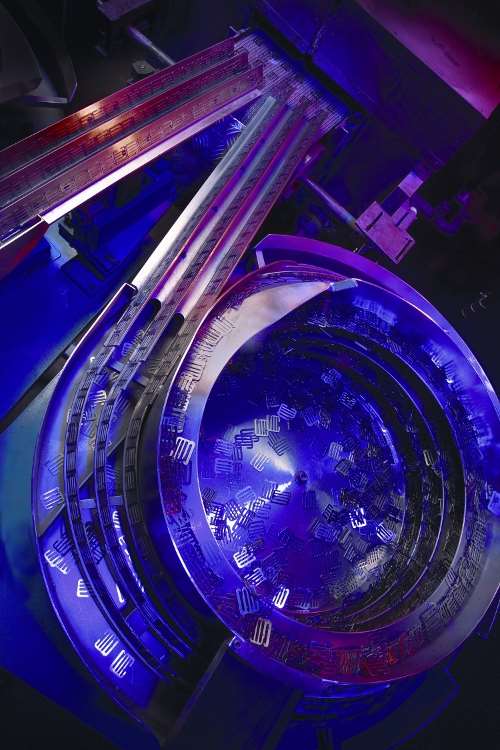

Take for example his proprietary Flow-Clad system of coating smaller parts at higher production rates, one that uses a tumbling method not usually found in many custom coaters.

“It’s an old-school system,” says Zimmerli, president of Plastonics in Hartford, CT. “It’s similar to a fluidized bed coating, but it’s different. There are not too many people in the U.S. who are doing it this way any more.”

The process consists of pre-heating the parts in an oven on a continuous moving mesh belt. The heated parts are then conveyed into a coating bowl were they are uniformly coated and automatically removed from the bowl.

The coated parts have a ‘sugary’ surface appearance, which is loosely adhered surface powder. This excess powder is removed in a de-dusting operation that results in a matte surface finish.

“Many customers accept parts in this condition for non decorative applications,” Zimmerli says. “If a high gloss finish is required, the parts are then fed into a post-fuser and conveyed on a continuous stainless steel belt where the coating surface is remelted to a smooth condition.”

Several years ago, Zimmerli and his crew were doing a cool million parts per week. But a lot of those jobs went overseas, although Plastonics is still doing 50,000–100,000 items each week.

“You can’t beat the cost of the way we do it,” he says. “It was under a penny a piece, which made it very affordable because it was automated. When you have to physically rack parts, you get into some costs.”

Zimmerli sells the Flow-Clad process on those benefits: Parts are totally encapsulated with no holding scar, and the labor costs are very low since an automated feeding process is used.

One of Plastonics’ customers, ADS Metal Products in New York City, makes parts for the garment industry, and brings a lot of its parts to Zimmerli to coat.

“It’s not necessarily cheaper, but it is better than anything else we could ever find,” says ADS manager Kurt Kopf. “The nylon coating completely encloses the entire part, which is absolutely needed for our parts.”

Plastonics has done well in various markets:

- Automotive: springs, clips, washers, wire guides and fasteners.

- Electrical: cable fasteners, ferrites, clips, thimbles, terminals and heat sinks.

- Fashion/Clothing: buckles, bra clips, hooks and buttons.

- Hardware: eyelets, hooks, rivets, screws and washers.

- Others: marine, jewelry, building or architectural.

While Plastonics’ fluidized bed coatings have a thickness between 0.007 and 0.015 inch or more, the Flow-Clad process results in thicknesses of about 0.003 to 0.007 inch, although a heavier coating can be specified, including up to 0.02 inch.

The company uses nylon, polyethylene, polyolefin and polypropylene material in its coatings.

Customers like ADS like those materials on their parts. “It seals it up very well, and that’s just what we needed,” Kopf says.

That’s because the parts have virtually no holding scars since they aren’t racked. Zimmerli says the parts are fed on a conveyor into an infrared oven where the coating is fused onto the material.

The part is then flipped and tumbled over and re-fed into the oven where the material on the other side is fused. Water is sprayed on the underside of the mesh conveyor to cool the belt and maintain the already-fused finish.

Zimmerli says he hopes to get the word out about his Flow-Clad process because it is a cost-saver for many projects.

“I just don’t think too many people even know that this process exists,” he says. “It will definitely save them money. It’s just getting the customer to understand what we can do for them.”

Zimmerli believes the reason he is one of the few to use the tumbling process is because it takes some time to master the technique.

“It can be tricky,” he says. “It takes time to learn how to get it right, and that may scare some people off. But once you know how it is supposed to work, it pretty much is a straightforward process.”

For information on Plastonics, call 860-728-3355, or visit Plastonics.com.

RELATED CONTENT

-

Simply heating up the substrate does not cure the coating. There are many variables to consider when choosing the best cure oven for your application...

-

The best protection against corrosion and UV exposure, says Axalta’s Mike Withers, is electrocoat and a super durable powder coating.

-

I am an engineer on a large yacht build project and urgently need information and advice on choosing a finish for the aluminum deck plates in the engine room.