Turbine Repairs Call for Selective Brush Plating Solution

IPS uses in situ repairs to minimize downtime and maintain revenue flows.

Integrated Power Services (IPS) is one of the U.S.’s leading independent provider of repair and maintenance services for electric motors, generators and mechanical power transmission components. Covering North America on a 24/7 basis, the Greenville, South Carolina, company integrates and supplies repair services, field services and product sales to thousands of customers working in asset-intensive industries.

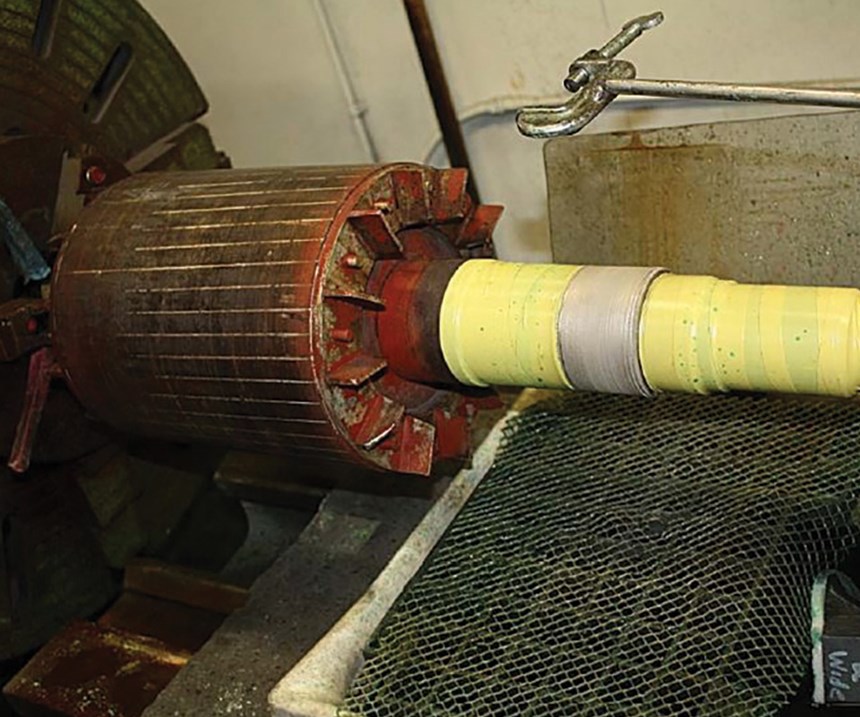

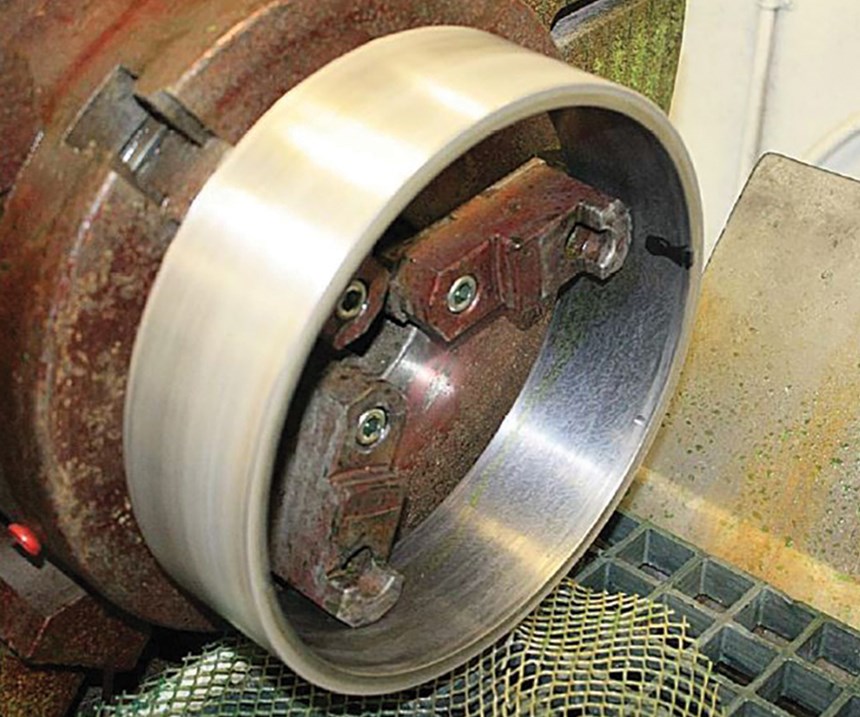

With services including turbine repairs and emergency and outage support, it is clear that IPS knows exactly what works—and what does not—when it comes to equipment and component maintenance. So, it is interesting to note that for over 30 years, IPS has been using a selective brush plating solution to repair and protect critical components such as the bearing fits on shafts, shaft journals and end bell bores.

In doing this, IPS has been able to offer durable and reliable repair options in place of costly replacements, helping customers to save money without having to compromise on performance. Indeed, one of the key advantages of using a selective brush plating process is that very often, repairs can be carried out in situ, minimizing downtime and thus maintaining revenue flows.

While selective plating is not a new process—developed first in France, just before World War II—IPS went with a solution that is a specific, proprietary selective plating process from SIFCO Applied Surface Concepts, a global supplier in selective electroplating, anodizing, chemical solutions and equipment. The Sifco Process is portable and allows the operator to plate a very specific area of a component, quickly and easily on site (and often in situ) and to the required thickness.

Featured Content

Repair or Replacement?

The equipment and components used in power generation and similar industries have to work very hard. Frequently exposed to high temperatures, heavy current loads and environmental contaminants, they are vulnerable to damage through wear and corrosion. When inevitably a certain amount of damage occurs, a choice must often be made between repair and replacement. Sometimes, issues also arise when fit—for example, a bearing housing or shaft journal—is fractionally ‘out,’ and must be trued.

Traditionally, options available in these instances have been machining and welding, sleeving and thermal spray. All of these, however, have key disadvantages.

“In machining and welding, sleeving or thermal spray, we have to remove a considerable amount of surface material to prepare for a repair, which is time consuming and can further damage the integrity of the component, because so much of the original material is taken away,” says Matt Peterson, machine shop supervisor for IPS. “In contrast, when we use the selective brush plating, it minimizes the removal of surface material, which limits the amount of preparation time and also means that more of the original steel or cast iron structure remains intact, ensuring strength is retained.”

Selective brush plating has safety advantages, too.

“When welding or thermal spray are used, these generate fumes and arc flash, which are hard to control and may be dangerous,” says Peterson. “There are minimal vapors involved in the process, and what little vapor exists is easy to manage with local ventilation.”

Surrounding Area Untouched

Unlike welding, which can deform the surrounding materials and generate extra work in machining, the selective brush plating process leaves the surrounding area completely untouched and—if the surface is correctly prepared for application—adherence is superb.

“The hardness value that the finished nickel plating lends to the repaired surface is a bonus, as many times, the plated surface is more wear- and corrosion-resistant than it was in its original state,” says Peterson.

At IPS, the Sifco ASC approach is used to plate to a thickness of up to 0.030 inch total, or 0.015 inch on each side of a journal or housing. While it is possible to build thicker layers, this involves stopping and restarting the process, and IPS operatives prefer not to do this. The company uses the plating process mainly for small and medium components, but also for some large motor component repairs.

The process offers advantages in terms of both time and money. Peterson says that while other methods of repair often require machining, even when the extent of the repair is small, the selective brush plating approach does not. Thus, repairs can be made quickly, which can be crucial to work and revenue flows, such as with power outages due to component damage.

“Designating an exact time savings figure would be very difficult, due to the vastly variable nature of the repairs and geometries we encounter,” Peterson says. “But a conservative estimate of the total time saved by using plating versus other methods would be 25 percent.”

Save the Cost of Buying New Units

When components are in bad shape, the plating process can actually save the cost of buying an entirely new unit; a cost that can, with replacement shafts, cost tens of thousands of dollars. That has certainly been the experience at IPS.

“Our company has been using selective brush plating process for more than 30 years,” says Peterson. “It has allowed us to offer our customers repair options on many of their worn or damaged components, which would otherwise have necessitated costly replacement.”

For IPS, the plating solution identified more than three decades ago is still serving them well today—and long may it continue to do so.

For information, visit ips.us and sifcoasc.com.

Originally published in the July 2017 issue.

RELATED CONTENT

-

A Chromium Plating Overview

An overview of decorative and hard chromium electroplating processes.

-

Choosing and Troubleshooting Copper Electroplating Processes

Learn more on this inexpensive and highly efficient process.

-

Stripping of Plated Finishes

The processes, chemicals and equipment, plus control and troubleshooting.