UV-Curable Basecoats and Clearcoats for Automotive Lighting

With the influx of plastic into automotive lighting in the early 1980s, a fresh market for coatings quickly emerged.

#economics #automotive

With the influx of plastic into automotive lighting in the early 1980s, a fresh market for coatings quickly emerged. UV-curable coatings were a very attractive match for this market partially due to the superior properties they offered, but also due to many processing related advantages such as reduced cycle times, smaller space requirements and elimination of pot life issues. The popularity of UV-curable coatings soon grew even further with the introduction of recyclable coatings. This was first done in the 1980s in the basecoat arena with both spray and flowcoat applications and has successfully been a standard process in the spray lens coating market since 1994. Additionally, some recyclable lens coatings applied through a flowcoat application have been available for several years, and continue to grow in popularity.

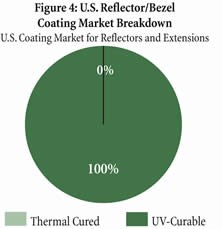

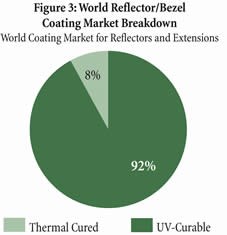

Due to continuous improvement of coating properties and their strong application advantages, today’s lighting market both domestically and globally has become well established with UV-curable products (Figures 1-4). UV clearcoats hold over 80% of the lens market and UV basecoats hold over 90% of the reflector/extension market.

Featured Content

Basecoats

In lighting applications, basecoats are defined as a coating applied directly to the reflector or bezel substrate. The purpose of this coating is to provide a smooth, high-gloss surface so that when metal, most commonly aluminum, is deposited via a vacuum process, the finished part exhibits an ornate, lustrous appearance. Typically, a protective topcoat is applied over the metal to create a sandwich and prevent oxidation of the metal (Figure 5).

The requirements of the basecoat are fairly basic. Among the more critical factors is to provide a smooth finish that accepts metallization, be able to withstand high heat and environmental cycling requirements and have adhesion to the substrate. Because of its high cross-link density and ability to cure in a matter of seconds, UV is better able to meet these stringent heat-resistant and environmental cycling properties.

In addition to the basic performance requirements, lamp design also plays a major role in formulation development. Many of the original lamp designs incorporated the flutes needed for optics in the lens (Figure 6). Because of this design, reflectors contained very few if any Class a surfaces; thus, many of the first UV-curable basecoats for automotive lighting were rudimentary. The majority of the first basecoats were based solely on the quickest curing resins available. Among these UV resins were epoxy acrylates or highly functional urethane acrylates blended with monomers.

However, in today’s lighting world, the function of the lamps has changed—not only must the lamps fulfill safety requirements, which continue to become more stringent, but they must do this in an aesthetically pleasing way. Thus, during the last 20 years, the coating has evolved from a solely functional purpose to a combination of function and design. Lamp designs considering both the reflector and the extension have become more complex with many models having deeper recesses. In addition, the majority of optics are now molded into the reflector rather then the top lens leaving no room for molding defects or environmental dirt (Figure 7). Further, hotter high-intensity discharge (HID) bulbs, which translate into higher-heat resistance needs, are more prevalent. Finally, there is a demand for more cosmetic finishes. The majority of these finishes are chrome looks—which because they require different metal alloys and deposition process—tend to introduce more stress into the coating sandwich on the final part. This increased stress typically reveals itself with increased cracking or haze in heat or environmental cycling tests.

What does all this mean for the coatings world? Coatings must continue to become more robust without increasing costs. To meet the increasing heat requirements and the critical appearance requirements on complex parts, it has become necessary to diversify from traditional UV basecoat strategy. The challenge is to develop coatings with excellent flow and leveling characteristics that are capable of hiding molding defects without building film too much, which could effect the optics. All this must be accomplished on thermosets such as glass reinforced bulk molded compound (BMC) and thermoplastics such as PET/PBT blends that are inherently more difficult to adhere to. UV basecoat technology has so far been able to step to the plate and meet all of these challenges.

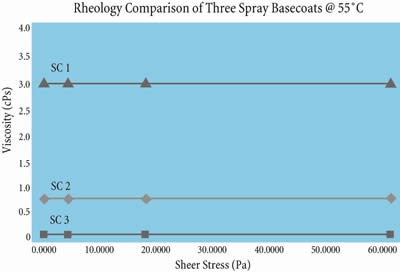

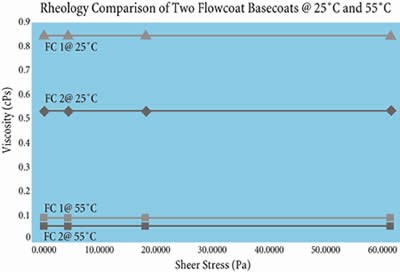

Flowcoat technology has been improved by developing coatings that are not as dramatically affected by the heat incurred in the flash zones (Figure 8). This allows for fewer runs and better coverage of airborne dirt or molding defects even at film builds as low as 15-20µm. For spray applications where often higher film builds are desired, coatings have been developed to allow for these high-film builds with reduced runs and sags. These improvements can be seen when viewing viscosity differences at temperatures, which mimic the heated flash zone (Figure 9). These new technologies, as well as many others in the market, make use of improved resin technologies such as modified acrylates, enhanced photoinitiators and different curing mechanisms or by blending conventional resins with traditional UV technology. However, just as important as improved coating technology, improved processing techniques have also played a vital role in meeting the OEM’s expectations.

The two most important aspects of processing UV coatings are cleanliness and following manufacturer processing recommendations. With the cosmetic requirements of headlamp reflectors increasing exponentially, it is very important to process UV coatings with as little contamination as possible. To do this, certain steps must be implemented. One good way to reduce the contamination is to reduce airborne particulates via air filtration. All air being supplied directly or indirectly to the coating system must be free of particulate contamination.

A second way to reduce contaminations is to filter the coatings. A fine filter as small as 1µm absolute is better at filtering, for it will remove practically all foreign materials. Proper filtration is especially important for flowcoating and reclaim systems. Because the coating is reused multiple times in these type of systems proper filtering is a critical step needed to ensure that all foreign material from the previous application and recovery is removed.

A second important item in UV processing is following recommendations set by the coating manufacturer. Because the various coatings’ manufacturers formulate differently, and because the various raw materials may react differently to UV exposure, it is important to follow recommendations set forth by the manufacturer rather than assume all UV formulations are identical. For example, a system based on highly-functional acrylates would be more sensitive to UV light than a system based on lower functionality components or one containing non-UV technology (dual cure). Such systems then may not require much UV energy in order to achieve full cure. Further, a dual cure system could require a different heat profile in the pre-UV flash zone or a post-UV heat cycle in order to cure properly into the film. The overall solids content of the coating and the type of solvents used in formulation can also dramatically affect the pre-UV flash requirement. In general, coatings require the following processing steps: application, ambient flash, heated flash and UV cure. The times, temperatures and UV energies vary depending on the specific coating and the intended application. It is important to monitor process conditions using periodic checks and to incorporate these into a control plan.

Clearcoats

The most scrutinized automotive lens application is by far that of forward lighting. When polycarbonate was introduced as a replacement for glass in the early 1980s, the challenges quickly unfolded to develop coatings that would mask its inherently weakweathering properties and poor scratch and chemical resistance. Opportunely, this has been done with success for many years, first with thermal coatings and now largely with UV-curable technology due to theperformance and processing advantages that UV offers. Thus, just as UV-basecoat technology has had to evolve to meet the ever changing demands of the automotive world, so too has UV-clearcoat technology for these lens applications.

Because of the location of the lens on the vehicle, it is subject to much harsher performance requirements. Critical among the long list of performance requirements are weatherability, scratch and abrasion resistance and resistance to a variety of environmental stresses. Some of the standard testing parameters are accelerated weathering by Xenon arc, natural weathering of three years Florida and Arizona monitoring changes in yellowness and haze, scratch resistance measured with steel wool and water soak at elevated temperatures.

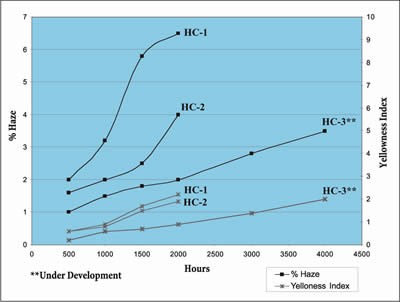

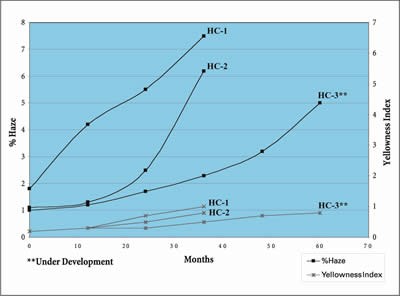

When the first UV-curable hardcoat for forward lenses was introduced in the late 1980s, meeting all of these requirements was quite a difficult challenge because extremely scratch resistant and weatherable resins were competing forces. However, materials available today offer much more resilience, marrying these competing forces to provide more robust materials. Additionally, the availability of enhanced photoinitiators and superior stabilizer blends allow for better properties across a much wider process window. The difference can especially be seen in weathering testing (Figures 10-11). This increased process window is essential because the trend is to apply less coating. Previously, film build targets varied greatly by manufacturer, but more stringent safety and testing requirements have narrowed the common target to 10µm or less.

Just as UV-basecoat technology success hinges on processing knowledge, so does UV-curable clearcoat technology. Very similar to basecoats, UV clearcoats have the same general pattern for cosmetics and processing. It is very important to maintain a clean environment to produce parts with the desired appearance and performance. All air flows into the process must be free of contamination; this includes any recycled process air or compressed air streams.

Paint filtration is also a necessity, especially if the UV clearcoat was reclaimed and rebalanced in house. A typical filtration process for clearcoat reclaim is four stages. Stage one includes a stainless steel wire mesh filter to remove any large pieces of contamination. Stages two through four include bag or cartridge filters gradually decreasing in size to ensure that all dirt contamination is removed. Commonly used filter sizes in these stages are 25µm, 10µm, and finally 3µm absolute. Recommended pumping pressures should be obtained from the filter manufacturer. A final important item on filtering UV coatings is the use diaphragm pumps. Diaphragm pumps, unlike centrifugal and gear pumps, will not sheer the coating; paint sheering can result in a multitude of processing and performance problems.

Proper processing is more important for weatherable UV-cured coatings versus basecoats, due to their exposure to the environment. Process checks should be performed on a regular basis. It is important to follow recommended processing parameters to obtain the optimum performance of these coatings. An example of the process steps for UV clearcoats are application, ambient flash, heated flash and UV cure. The values for time, temperature and UV energy are dependant on the coating and the end use. The processing of UV coatings is becoming easier with better control technology and better measurement capabilities as well as more reliable and cost effective equipment.

Conclusion

Due to the changing automotive lighting market, it is increasingly important to develop more robust coatings that are cost effective yet remain easy to process. In a market where reduced cycle times, increased productivity, and leaner manufacturing are critical success factors, it is imperative for UV-curable coatings to meet these demands and continue to push the performance envelope. Further, with its proven success in the lighting market, UV-curable coatings have become a viable option for other automotive applications.

Note: This article originally appeared in RadTech Report, November/December 2003. Reprinted with permission from RadTech International North America

RELATED CONTENT

-

Automotive Powder Coating

The automotive market and its requirements for powders...

-

Impact of REACH Regulation on the Global Finishing Market

This paper is a peer-reviewed and edited version of a presentation delivered at NASF SUR/FIN 2012 in Las Vegas, Nev., on June 12, 2012.

-

Is it Time to Revisit your Plastic Metallization Process?

The plating on plastics (POP) market has evolved to include an ever-broader range of substrates, huge increases in selective plating demand, using tools such as two-shot molding and laser ablation.