There is no question that Cara Burzynski is the president of Aerodynamics in Seabrook, New Hampshire, and that her husband, Gregg, is the chief executive officer.

But walk around their 40,000-square-foot finishing operations, and you get the feeling that one of their young offspring is certainly holding influence on how the business is run and where it is headed.

Featured Content

Anya Burzynski is the operations and business development manager in title and responsibility, and her 26-year-old mind has wielded a strong influence on the company’s forward thinking and approach to customer service.

To wit: the 30-employee shop is 50 percent millennials and 50 percent females. It recruits people who fit into their dynamic, instead of taking applications at the door. The young faces and feminine touch on most of its major products is a byproduct of Anya moving the company to what is reality in 2019.

“This didn’t just happen,” she says of the youth movement and diverse workforce. “I’ve been doing a lot of recruiting the past two years, even before I started working here. I was trying to find a new generation of platers, those who were young and hungry to be in this business.”

Major Approvals and Certifications

Make no mistake, the shop has extensive roots and capabilities. It was founded in 1989 and is Nadcap approved in both Aerospace Quality Systems (AC7004) and Chemical Processing, as well as certified in International Traffic in Arms Regulations (ITAR) and Federal Firearms Licensed with the U.S. Department of Justice.

It also has approvals from all the major aerospace and defense OEMs, including GE Aviation, Lockheed Martin, Northrup Grumman, Parker, Raytheon, Sikorsky, SpaceX, Teledyne, UTC Aerospace and others.

But when Anya came on board, she was determined to bring an old-school business run by her parents—albeit a successful one—into the new realm of technology and ideas. One of the first projects was upgrading the Aerodynamics website by putting a fresh look and perspective on it.

The site now tells a graphically pleasing story about what the company does and whom their customers are, as well as showing off their handiwork.

In fact, when Aerodynamics hired Emerson Bilodeau as director of quality and engineering last year, he confided to the owners that he almost didn’t take the position after reviewing their old website.

“When Emerson started, he said how amazed he was that he took the job when he saw our old site,” Cara says. Adds Gregg, “He was embarrassed to tell anyone he worked here because of how it looked and the impression it gave. That’s when we knew we had to do something.”

Recruiting ‘Brainpower’

Bilodeau, a 2014 Ivy League graduate from Cornell, was recruited by Anya, a graduate of Providence College who also earned a master’s degree from Boston University.

“It was a lot of networking and talking to people whom I already knew who had the right background,” she says. “I would tell them about this company my parents owned and ask them if they would be interested, and a lot of things fell in our favor and we landed some real rock stars.”

It is not to say Anya has usurped authority and rubbed anyone the wrong way. Cara and Gregg are the final authorities on all calls, and Tom Gilligan, vice president of operations and sales, is as talented as they come. It’s a message the young Burzynski fully understands.

“Cara and Gregg built this business and did all the hard work to get us where we are, but they need people who are talented to help run it with them,” Anya says. “I think we’ve hit on a few things already, and we’ve got some new talent who are in management positions who are really revolutionizing the company.”

The youth movement actually started with Gregg, who has owned the company since 1989. Two years ago, he was sitting in a manager’s meeting with his staff when a sudden realization struck him.

“I was looking around the table and I realized that no one had come to me with an original idea in maybe the last five years,” he says. Later that day, he called Cara—who had a 30-year career as a research nurse in nearby Boston—and told her she needed to quit her job and join the metal finishing company.

“I told Cara, ‘We need to get some brainpower in here,’” he recalls. “We were just doing the same thing every day, just like everybody else, and we needed to start thinking differently in order to stay competitive.”

Focusing on Core Processes

Aerodynamics specializes in the aerospace, military and defense industries, but also serves a large customer base in the commercial, industrial and medical fields. Gilligan says the company focuses on a set of core processes for their customers.

“We only do five things here,” he says. “We’re not trying to be everything to everybody. That just doesn’t work well for us. We focus on anodize, passivate, chrome, nickel and chem film black oxide. We keep it simple and we grow our expertise and our training.”

That wasn’t always the case. Before the shop moved into its current 45,000-square-foot facility, it worked out of a 15,000-square-foot space next door where they offered nearly every finish under the sun—gold, rhodium, cadmium, copper and tin, as well as anodize and passivate and other core coatings.

“We were doing about 105 different types of finishes, and when we bought this building in 2008 and moved into larger space, we made a concerted effort to simplify things,” Gilligan says. “It made us a better company because our core competencies got better, and we saw more incremental growth.”

Aerodynamics spends a considerable amount of time masking very detailed parts for customers. It is something that has built their reputation and attracted new customers who need that precise attention to detail.

“We’re not one of those shops that uses day labor for its masking operations,” Gilligan says. “There’s no bus that pulls up on a Monday and workers file in, and it’s a different crew on Tuesday. We have maskers here who have been with us mostly over two years, and some as high as 15 years. It’s a profession to them. In our business, we can’t have turnover in the masking area, and it starts with a corporate culture of that.”

Addition of Zinc Nickel

Bilodeau’s job as director of quality and engineering is to work with customers on their requirements for each part (including intricate masking) and making sure that gets fulfilled by the Aerodynamics staff prior to and after finishes.

“Whenever we get a job, we try to work very closely with our customer to make sure we give them exactly what they want,” Bilodeau says. “The other component is making sure the customer fully understands the plating process, about how we plan to rack the part, and let them know what works and what doesn’t work. It’s all about meeting their expectations.”

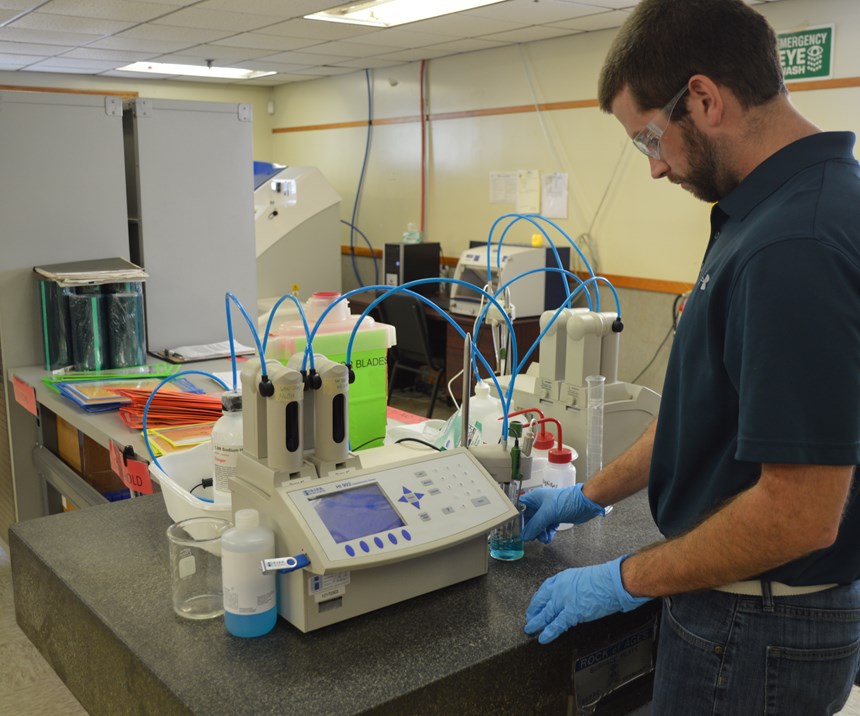

Another young mind at the shop is Owen Labrie, the head chemist who manages the Aerodynamics lab. Labrie has a chemistry degree from Lake Forest, and was recruited by Anya to be an integral part of their operation.

Aerodynamics now has a comfortable breakdown of 70 percent of their work is aerospace, 20 percent is defense contract work and the remaining 10 percent is a commercial base from nearby manufacturing shops (which mostly includes nuclear and energy).

Last fall, the company began installing a new zinc-nickel line with hopes of getting additional work in the automotive sector, as well as more aerospace work.

Anya says that going forward, the company will maintain its strategy of offering core finishes and being selective in who they bring on as customers.

“We like to stick to our guns and do what we do best,” she says. “If a company starts to make wacky requests, then they probably won’t be our customer, and we are all okay with that. Fortunately, we do have the luxury to find the companies and the purchasers that we want to work with.”

Visit aerodynamicsmetalfinishing.com

RELATED CONTENT

-

Anodizing for Bonding Applications in Aerospace

Anodizing for pre-prep bonding bridges the gap between metallic and composite worlds, as it provides a superior surface in many applications on aluminum components for bonding to these composites.

-

Plating Q&A: Can you color stainless steel?

Our expert, Art Kushner, says yes, you can color stainless steel, but it is not a process that is typically performed in a plating shop. Read more about his answer.

-

Aluminum Surface Finishing Corrosion Causes and Troubleshooting

In this paper, a review of several process solutions, examining coolants, solvent cleaning, alkaline clean/etch and deoxidizing/desmutting, listing intended and unintended chemical reactions along with possible mechanisms that would favor corrosion formation.