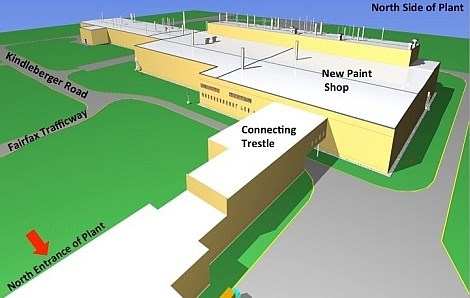

GM Fairfax Breaks Ground On New Paint, E-Coat Shop

450,000-square-foot, bi-level paint shop at the Fairfax Assembly and Stamping Plant in Kansas City

#masking #pollutioncontrol #curing

Featured Content

General Motors broke ground and began construction on an all-new, 450,000-square-foot, bi-level paint shop at the Fairfax Assembly and Stamping Plant.

The paint shop is part of a $600-million investment in the plant, which builds the Buick LaCrosse and Chevrolet Malibu.

Construction will take place in five major phases during the next two years. When the paint shop is complete, the plant’s footprint will be 3.7 million square feet – an increase of 15 percent.

“When complete, our plant will be able to continue to paint cars with a flawless finish while using a lot less energy and resources,” said plant manager William Kulhanek. “The addition of this paint shop also demonstrates GM’s commitment to maintain a strong presence in the Kansas City community.”

The all-new paint shop will feature substantial technology upgrades including:

- A 20-percent smaller footprint, use up to 50 percent less energy per vehicle and reduce Volatile Organic Compound emissions

- GM-patented Radiant Tub Ovens designed to use 20 percent less natural gas and 40 percent less electricity

- Thin Film Technology, which reduces water use and maintenance and eliminates hazardous chemicals from the waste stream

- Hyper Throw E-COAT, which places more coating in cavities and recesses for optimal corrosion protection.

RELATED CONTENT

-

Alkaline Cleaning Guide

Gregg Sanko, Senior Chemist, Oakite Products, Inc. provides an overview of the alkaline cleaning process.

-

Cleaning Prior to PVD/CVD Coating

Determining the cleanliness and chemical de-coating of PVD/CVD layers.

-

Cleaning Magnesium

Question: What is the recommended chemical cleaning process and composition prior to electroless nickel plating for magnesium?