Do I Have a Finishing Story for You

Non-disclosure agreements keep many ingenious projects under wrap, but a Brooklyn plating shop has a heck of a tale to tell about a huge job it pulled off.

Oh, the stories that finishers could tell—if only they could.

Secrecy is a big part of how the plating and coating industries work in the world we live in today, with non-disclosure agreements (NDAs) handed out like breadcrumbs to pigeons.

This means that the masterful work your plating shop or powder coating facility just performed for a very stringent client may never see the light of day on your website or colorful brochure, all because some engineer somewhere for some company thinks the world will crumble if anyone sees the part you just coated.

Granted, there are absolutely some justifiable reasons why some parts must be kept secret, either for national security or because they are prototypes, but for the most part, there seems to be an overabundance of NDAs out there, and, take it from a guy who is always taking photos in shops for articles, nothing grates on me more than hearing “you can’t shoot that.”

So, imagine my disappointment when my pal David Epner at 108-year-old Epner Technology in Brooklyn, New York, was tasked back in 2010 with a plating job that had probably never been done before: gold plating 103 bell-jar-looking things, each 13 feet tall and close to 40,000 pounds.

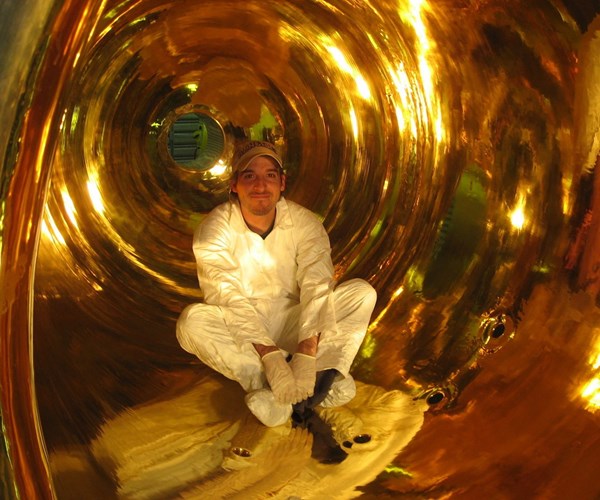

“To my knowledge, nothing like this had ever been plated before, much less 103 of them,” says Epner, who has plated some pretty rare and exotic items in his decades in the business. “Each took a Kilo of our proprietary Laser Gold on the inside. The anode holder and fluid displacement shape was custom-made by a boat builder.”

To get a load of what these parts looked like, search our News section on PFOnline.com. Spectacular eye candy for the plater and impressive in looks. Epner had to keep his lips sealed about what he was doing because of the NDA, but he definitely wanted to share the project with others because of its uniqueness and challenge.

It was only recently that Epner was permitted to talk about it, and if you are in the finishing industry (and I assume if you are reading this you are), you can imagine the glee in his voice we he describes how his shop pulled off this monster of a job.

“Our loading dock was the only space that had enough headroom,” he says. “We had to modify the building to get the gantry holding the bell jar inside.”

Why Epner and his team took on this project is beyond me, but I suspect that no one else wanted to do it and the manufacturer paid a pretty penny to get it done. Even Epner says he would probably think twice before taking on a project like this again, but knowing him, I certainly realize every man has his price.

“The big non-recovery cost, which was about $1.5 million, was moving our entire closed-loop evaporative recovery waste-treatment system from the loading dock to another venue inside the building,” he says. “Every rinse tank had to be replumbed.”

The customer needed the bell jar to be gold plated to reduce a chemical reaction inside the vessel, but that is about as much as Epner can say about what the actual part was used for. He says there was “a lot of heat taking place inside the vessel,” and instead of the heat going into the water-cooling jacket, it was reflected back into the process.

“A first, we just stood around and asked, ‘how the hell do you plate a thing that big?’” he says. “We finally came to the realization that the secret to doing this job was treating it like a big washing machine, meaning fill and drain, fill and drain. We just made the vessel its own tank.”

The other challenge Epner and his team had to overcome was creating a plug, which Epner called a “giant fiberglass condom” that would perform two functions: be the support for the platinized titanium anode and be the support for the pure nickel bars. It would also serve as a liquid displacement vessel.

Epner Technology co-owner J.R. Candiloro engineered the project, and it worked just as planned.

“Without that plug, filling this chamber would have taken $3 million worth of gold,” Epner says. “We had about an 8-to-10-inch gap between the anode surface and the bell jar surface, and that worked well for us. J.R. did a remarkable amount of engineering on this to make it work.”

I’m sure there are hundreds of other projects out there in the finishing world that can’t be told until the NDA expires of the customer goes out of business, which is what happened in Epner’s situation. It’s a shame the complexity of such projects can’t be shared, but I know that many of our readers have taken on these types of projects over the years.

It is one of the reasons why Epner whispered to me years ago when I first met him, “Do I have a story for you some day.” I’m glad he finally shared his tale, and I know many of you are busting at the seams to tell yours, too. In due time.

RELATED CONTENT

-

An Overview of Electroless Nickel Plating

By definition, electroless plating is metal deposition by a controlled chemical reaction.

-

Masking for Surface Finishing

Masking is employed in most any metal finishing operation where only a specifically defined area of the surface of a part must be exposed to a process. Conversely, masking may be employed on a surface where treatment is either not required or must be avoided. This article covers the many aspects of masking for metal finishing, including applications, methods and the various types of masking employed.

-

Gold and Silver Plating Basics

An overview of precious metal electroplating processes.