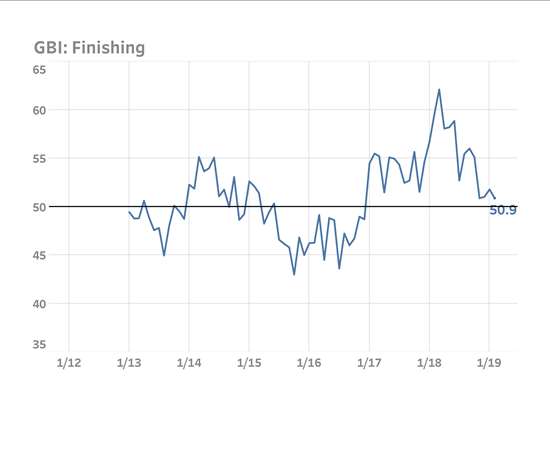

Finishing Index Reports Modest February Expansion

February Finishing Index: 50.9

The Finishing Index logged its 26th consecutive month of growth with a February reading of 50.9. The Index has reported slowing growth over the last year as the Index has fallen from an all-time high in March 2018. Despite the decline in the Index over the last 12 months, the finishing industry has reported consecutive months of expansionary readings since January 2017. The latest reading was supported by supplier deliveries, production and employment. The components which pulled the index lower (calculated as an average of the components) included backlog, new orders and exports. All three of these components contracted during the month.

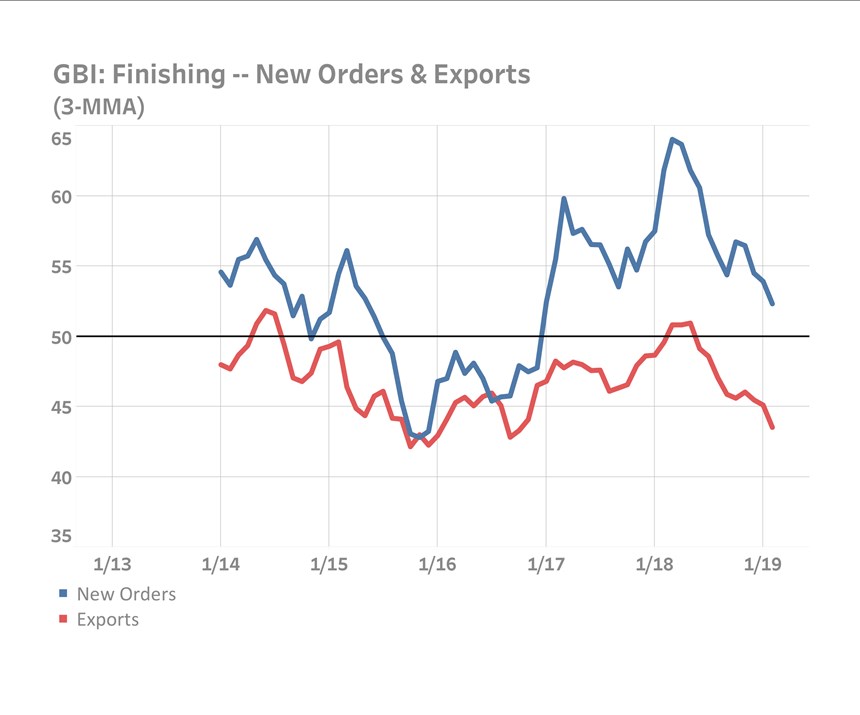

February’s data reported the Finishing Index’s first contractionary reading for new orders since December 2016. The new orders component (which measures the total expansion or contraction of orders in the finishing industry) has experienced slowing growth since registering an all-time high in March 2018. Beginning in the second half of 2018, exports began contracting and have done so at an accelerating rate through February. That total new orders contracted significantly less in February than did exports suggests that domestic demand conditions are better, although apparently not able to fully offset the latest reported weakness in foreign demand.

RELATED CONTENT

-

Preparation of Stainless Steel for Powder Coating

Should type 316 stainless steel castings be sandblasted before powder coating, or can they be chemically etched? Should the parts be pre-heated in an oven before coating?

-

The Powder Coating Process

Powder coating is one of the most durable finishes that can be applied to industrial manufactured products, and offers excellent corrosion protection and is very safe because of its lack of volatile organic compounds. To understand the powder coating process you should start with the fundamentals.

-

Understanding Infrared Curing

Infrared cure is gaining increased attention from coaters as a result of shorter cure cycles and the possibility of smaller floor space requirements when compared to convection oven curing.

.jpg;width=70;height=70;mode=crop)