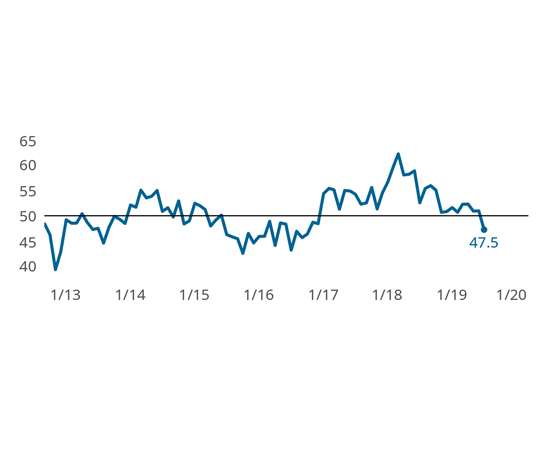

Finishing Index Ends 30 Consecutive Months of Expansion

June Finishing Index is 47.5, over five points lower than the reading from the same month one year ago.

#economics

The Finishing Index registered its first contractionary reading since 2016 with a July reading of 47.5. The latest Index reading is over five points lower than the reading from the same month one year ago. Index readings above 50 indicate expanding activity, while values below 50 indicate contracting activity. The further away a reading is from 50, the greater the magnitude of change. The latest Index reading was supported by expanding supplier deliveries. The Index calculated as an average of its components was pulled lower by contracting activity in employment, new orders, exports and backlogs. Employment activity contracted in July for only the second time since the fourth quarter of 2016. The last time employment activity contracted was during November 2018.

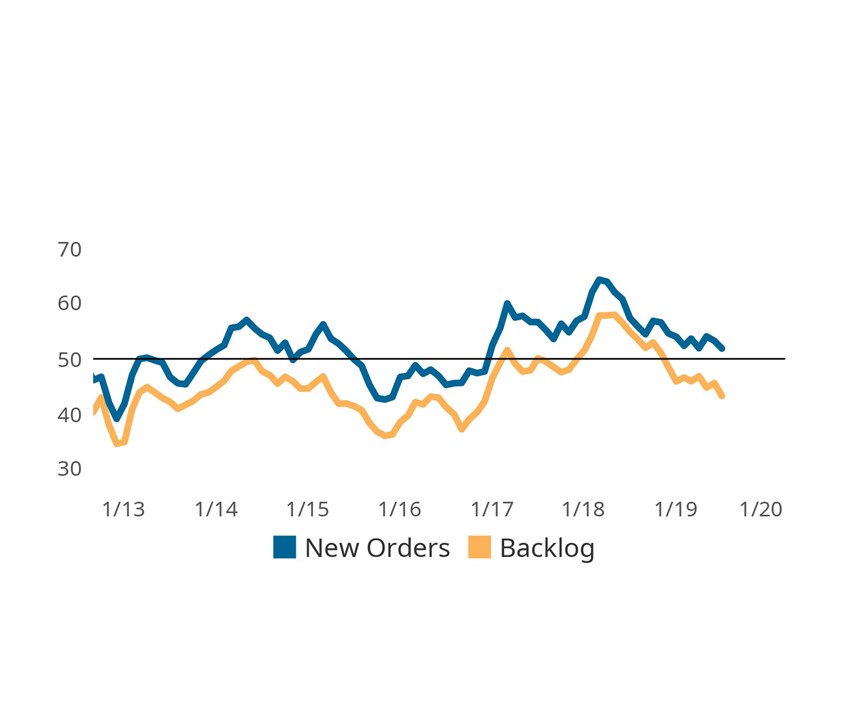

July marks the second time in 2019 that new orders have contracted. In the year-to-date period, new orders readings have averaged 52.6, while production activity has averaged 56.4. This spread in new orders and production is one reason for the last nine months of contracting backlogs. July’s contraction in new orders and unchanging production activity further weighed on backlog activity. The last time that backlogs contracted at this rate was during the second half of 2016.

RELATED CONTENT

-

Fixing Corrosion Between Anodized Aluminum and Steel

Anne Deacon Juhl, Ph.D., with AluConsult, says Galvanic corrosion is due to an electrical contact with a more noble metal or a nonmetallic conductor in a conductive environment.

-

What is the Correct Anodizing Specification?

My company fabricates aluminum and steel pedestrian bridge railing among other bridge parts. We recently got an aluminum railing job that called for “Type I” anodizing per MIL-A-8625. There was no anodic coating thickness called out. We are not anodizers and we are at a loss as to how to write up a meaningful anodizing specification for this railing.

-

Anodizing for Bonding Applications in Aerospace

Anodizing for pre-prep bonding bridges the gap between metallic and composite worlds, as it provides a superior surface in many applications on aluminum components for bonding to these composites.

.jpg;width=70;height=70;mode=crop)