Possibilities From Electroplating 3D Printed Plastic Parts

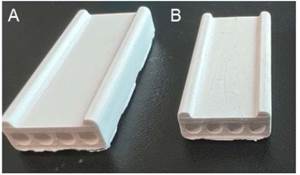

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

#additive-manufacturing

NASF/AESF Foundation Research Project #123: Electrochemical Manufacturing for Energy Applications - 6th Quarter Report

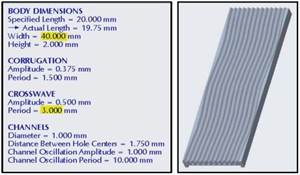

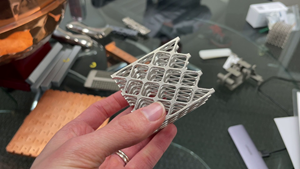

The NASF-AESF Foundation Research Board selected a project on electrodeposition toward developing low-cost and scalable manufacturing processes for hydrogen fuel cells and electrolysis cells for clean transportation and distributed power applications. In this period, work focused on 3D printing anode support for solid oxide fuel cells, SOFC (or cathode for solid oxide electrolyzers, SOEC) based on our designed optimization outlined in the previous report.

#nasf #additive-manufacturing

NASF/AESF Foundation Research Project #123: Electrochemical Manufacturing for Energy Applications – 4th and 5th Quarter Report

The NASF-AESF Foundation Research Board selected a project on electrodeposition toward developing low-cost and scalable manufacturing processes for hydrogen fuel cells and electrolysis cells for clean transportation and distributed power applications. During the reporting period, efforts were focused on planning the overall project work, with the eventual goal of manufacturing an improved design for a Solid oxide fuel cell anode supported flat tube (SOFC).

#energy #nasf #additive-manufacturing

5 Big Themes in Additive Manufacturing at Formnext Forum: Austin

As manufacturing advances with additive, the advance increasingly emphasizes these five themes.

#additive-manufacturing

Plating Additively Manufactured Plastic Parts

Using electroplating to enhance the structural properties of 3D printed parts.

#photofinish #additive-manufacturing

NASF/AESF Foundation Research Project #123: Electrochemical Manufacturing for Energy Applications – 3rd Quarterly Report - Part I

This is the third quarterly report, covering work during July-September 2022 and consists of a review, “Formidable Challenges in Additive Manufacturing of Solid Oxide Electrolyzers (SOECs) and Solid Oxide Fuel Cells (SOFCs) for Electrolytic Hydrogen Economy toward Global Decarbonization,” prepared and submitted to the peer-reviewed Ceramics Journal for publication. What follows here is Part I of the review paper, covering the literature on additive manufacturing of SOFCs and SOECs. Part II, covering opportunities and challenges for additive manufacturing technologies, will be published in January 2023.

#nasf #additive-manufacturing

NASF/AESF Foundation Research Project #123: Electrochemical Manufacturing for Energy Applications – 3rd Quarterly Report - Part II

The NASF-AESF Foundation Research Board has selected a project on electrodeposition toward developing low-cost and scalable manufacturing processes for hydrogen fuel cells and electrolysis cells for clean transportation and distributed power applications. This third quarterly report consists of Part II of a review paper, prepared and submitted to a peer-reviewed journal for publication, covering opportunities and challenges for additive manufacturing technologies. Part I, covering the literature on additive manufacturing of SOFCs and SOECs, was published in December 2022.

#nasf #additive-manufacturing

Evonik Increases Additive Capacities for Architectural Paints

Evonik's Coating Additives business line is increasing capacities of two additive product groups for architectural paints.

#additive-manufacturing

NASF/AESF Foundation Research Project #123: Electrochemical Manufacturing for Energy Applications – 2nd Quarterly Report

For 2022, NASF-AESF Foundation Research Board has selected a project on electrodeposition toward developing low-cost and scalable manufacturing processes for hydrogen fuel cells and electrolysis cells for clean transportation and distributed power applications. This report is the 2nd quarterly report, covering work during April-June 2022 and consists of an edited manuscript, “Manufacturing and Thermal Shock Characterization of Porous Yttria-Stabilized Zirconia for Hydrogen Energy Systems.”

#nasf #additive-manufacturing #energy

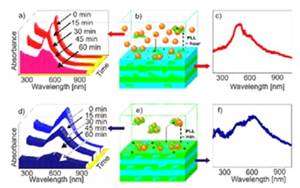

Nanostructure of the Anodic and Nanomaterials Nanoparticles in Polyelectrolyte Multilayer-by-Layer (LbL) Films

Microstructure and elemental characterizations have indicated that the finish of a coating with a Layer-by-Layer (LbL) film results in a closely multilayered coating with a smoother surface. In this paper, the principles of assembly are discussed together with the properties of nanoparticles and LbL polymeric assembly essential in building hybrid coatings.

#nasf #additive-manufacturing #surfin

Five Trends in Surface Finishing

You’re at IMTS because you’re interested in moving your business forward. No matter what role you fill in the manufacturing process chain, it’s important to consider how your parts will be finished. Here are five trends in surface finishing.

#additive-manufacturing #sustainability

NASF/AESF Foundation Research Project #123: Electrochemical Manufacturing for Energy Applications - 1st Quarterly Report

For 2022, NASF-AESF Foundation Research Board has selected a project on electrodeposition toward developing low-cost and scalable manufacturing processes for hydrogen fuel cells and electrolysis cells for clean transportation and distributed power applications. This report introduces the project and outlines the work to be undertaken.

#nasf #additive-manufacturing

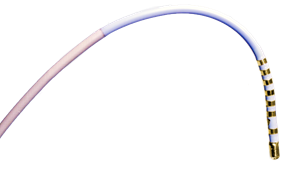

ProPlate Uses Pure Platinum and Gold in Additive Plating Process

The company says pure gold and platinum are superior at conducting electricity and have other performance advantages compared to platinum-iridium alloys and stainless steel.

#additive-manufacturing

Keyland Polymer, PolySpectra Powder Coat 3D-Printed Parts

Keyland’s color-matching capabilities, combined with PolySpectra's COR family of materials, now enable consumer and industrial brands to adopt a new approach to digital manufacturing.

#additive-manufacturing

Leading AM Trade and Media Organizations Unite to Launch Formnext USA Chicago in Spring 2025

Mesago Messe Frankfurt the organizers of Formnext and Messe Frankfurt USA announce a strategic partnership with the Association For Manufacturing Technology and Gardner Business Media. The new show creates one event in the United States dedicated to all aspects of industrial additive manufacturing.

#additive-manufacturing

Throughput Consulting Hires Cyber Security Officer

Throughput Consulting has hired Joe Coleman as its new cyber security officer to help customers achieve compliance with NIST 800-171, CMMC and DFARS.

#military #additive-manufacturing #regulation

Phillips Federal Adds Bel Air Finishing Technology

Bel Air Finishing's post processing technologies will support Phillips' Public Private Partnership, providing training for finishing for 3D printing.

#additive-manufacturing #workforcedevelopment

Additive Manufacturing Media Releases Education Presentation Series

Additive Manufacturing Media is releasing AM InDepth, a series on the future of 3D printing/additive manufacturing, as a part of IMTS Spark.

#workforcedevelopment #additive-manufacturing #education

Custom Precision Cleaning System for Additive Manufacturing

Layton Technologies designed a custom solvent cleaning system to remove wax from 3D-printed parts, replacing an inefficient manual process.

#additive-manufacturing

Technical Coatings for Additive Manufacturing Show Promising Results

Technical Coatings enable smooth and sealed surfaces with specific functions.

#additive-manufacturing