Eliminating No-Value-Added Services Adds Value for Customers

Answering questions about how to best meet customer needs led this Products Finishing Top Shop to stop using trucks to provide value-added services and instead, start offering in-house solutions.

#aerospace #topshops

Top Shop Savors Past 20 Years of Prosperity

This one-stop finishing shop was rescued by new management in 2004. Since then, its rejuvenation has brought substantial growth and success to the business.

#management #aerospace #topshops

Sherwin-Williams 2024 Aerospace Coatings Calendar Winners

The annual program recognizes the exceptional craftsmanship and creativity of aircraft painters and designers who rely on Sherwin-Williams aerospace coatings.

#aerospace

Single Stage Topcoat Delivers Consistent, Colorful Finishes

The 858 Series Skyscapes from Sherwin-Williams Aerospace Coatings comes in multiple gloss levels.

#aerospace

NADCAP Shop Digitizes to Eliminate Paper Trail

Customizable ERP software has transformed a 27-year-old manual metal finishing job shop into a state-of-the-art paperless company with full digital traceability in about 10 months.

#aerospace #military

High-Flexibility Aerospace Filler Fills Seams, Rivets, Small Spot Repair Areas

Fill Bond Flex Aerospace Filler restores aircraft exteriors by concealing surface imperfections.

#aerospace

Episode 36: An Interview with Peter Mirabello, Metal Finishing Technologies LLC

Peter Mirabello of Metal Finishing Technologies discusses his passion for surface finishing and trends shaping the industry today.

#aerospace

A Smooth Transition from One Anodizing Process to Another

Knowing when to switch from chromic acid anodizing to thin film sulfuric acid anodizing is important. Learn about why the change should be considered and the challenges in doing so.

#aerospace

Aerospace Conductive Coating Provides Adhesion, Fluid Resistance

Conductive coating (CM0485115) provides a high-conductivity solution for dissipating static on aluminum and composite aircraft.

#aerospace

The Best Method for Coating Full-Size Aircraft

John Owed from Carlisle Fluid Technologies analyzes the difference between using air-assisted airless, air spray and other technologies for coating a full-size aircraft. Which is better?

#aerospace #asktheexpert

PPG, Satys Partner for Aerospace Ecoat System in France

PPG is partnering with Satys, a French industrial group active in aircraft sealing, painting and surface treatment.

#aerospace

Top Shop Emphasizes Dedication, Work Ethic

With a primary focus on aerospace and defense work, American Metaseal Corp. of Arbutus, Maryland, has qualified as a Top Shop on multiple occasions.

#military #aerospace #vacuum-vapor

Finishing High Reliability, Function Critical Parts

From safety critical automotive and aerospace components to lifesaving medical micro-components and implantable devices, Indiana-based Electro-Spec finishes applications that require zero failure rates.

#medical #military #electronics

Digital Service for Improving Coatings' Maintenance Schedules

Aerofleet Coatings Management is a digital service developed to assist with coating replacement and maintenance.

#aerospace

AkzoNobel Uses VR for Training Airline Apprentices

The virtual reality technology provides a paint booth and spray gun that enables trainees to work and master their skills without losing parts in the process.

#workforcedevelopment #aerospace #Industry40

Multistage Wash System for Continuous Cleaning Efficiency

Gas-heated conveyor parts washing system is said to provide continuous, efficient cleaning throughout the multiple stages of the system.

#aerospace #automotive

Anodizing for Bonding Applications in Aerospace

Anodizing for pre-prep bonding bridges the gap between metallic and composite worlds, as it provides a superior surface in many applications on aluminum components for bonding to these composites.

#aerospace #basics

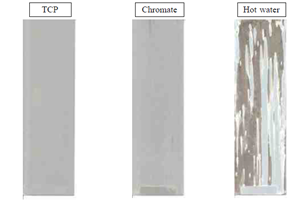

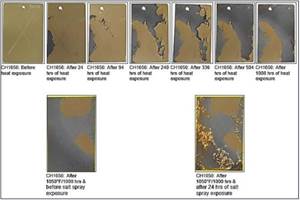

Development of a Novel Hexavalent-Chromium-Free Aluminum Sacrificial Paint

Hexavalent chromium is a known carcinogen, repro-toxin, and mutagen. Its elimination is of high importance to the aerospace industry, which has struggled to find high performing alternatives. Legacy aluminum sacrificial paints have traditionally utilized hexavalent chromium to prevent corrosion and coatings which are equal to or better than have been difficult. This first paper discusses the novel process from the supplier point-of-view.

#aerospace #nasf #surfin

Hexavalent-Chromium-Free Aluminum Sacrificial Paint Validation

Hexavalent chromium is a known carcinogen, repro-toxin and mutagen. Its elimination is of high importance to the aerospace industry, which has struggled to find high performing alternatives. Legacy aluminum sacrificial paints have traditionally utilized hexavalent chromium to prevent corrosion and coatings which are equal to or better than have been difficult. This second of two papers discusses the hexavalent-chromium-free process from the user point-of-view in terms of the process validation work by Rolls Royce Corporation.

#aerospace #nasf #surfin

VST Appoints Marketing and Communications Director

Julie Sims has been named as Valence Surface Technologies' marketing and communications director.

#management #aerospace