PPG Highlights Coatings for Battery EVs

PPG will showcase coatings for electric vehicles and batteries at North American International Detroit Auto Show and The Battery Show.

#automotive

Ecoat — An Entrepreneurial Approach

Job shop style approach for a captive ecoat line encourages ownership, innovation.

#automotive

Dodge Notes the “Last Call” with Power—and Paint

As the Dodge Charger and Challenger leave the lineup, the muscle car purveyor is putting out the final vehicles and offering paints from the cars’ performance past.

#automotive

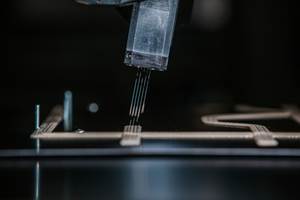

Flexible Paint Applicator Automates Car Sealing Process

Dürr’s new EcoSealJet Pro applicator enables process improvements and material savings that are good for both budgets and the environment.

#automotive

Episode 22: An Interview with Gary Vasilash, Gardner Business Media

Transportation editor Gary Vasilash discusses the automotive industry today and what the future might hold for surface finishers.

#management #automotive

Smart Automotive Paint Booths: Embracing Industry 4.0

Automation, digitization, connectivity, remote process management tools help automakers, suppliers paint parts, vehicles at lower cost, reduced carbon footprint.

#Industry40 #automotive

How Ford Is Honoring the F-Series with Color

Ford celebrates 75 years of F-Series trucks with five color options.

#automotive

The Missouri S&T Coatings Institute Offers Paint Courses

The “Introduction to Paint Formulation” course offered, August 15-19, 2022, is intended to give fundamental knowledge of how to approach a starting formulation and troubleshoot it.

#aerospace #automotive

Online Repair Calculator for Vehicle Refinishing

AkzoNobel’s tool identifies the carbon levels associated with the painting and drying process — including the energy consumed — and is linked directly to the vehicle refinishing products being used.

#automotive

Non-PFAS Wetting Agents for Decorative Chromium(VI) Plating

This article is based on a presentation given at NASF SUR/FIN 2022, in Rosemont, Illinois, in Session 6, Responses to PFAS / PFOA. It follows the case study of three facilities’ conversion from PFAS-containing wetting agents to non-PFAS equivalents, eliminating PFAS and moving forward with a smaller and more sustainable environmental footprint. The journey of conversion from PFAS-containing wetting agents in both chromic-sulfuric etch and hexavalent decorative plating tanks can be complicated and winding due to deep rooted standard industry practices, as well as state and federal regulations. Outlined here is a clear course of action that led to eliminating PFAS from the facilities’ wetting agent strategies.

#sustainability #automotive #nasf

Sames Kremlin Hires Automotive Sales Application Engineer

John Becker has over 30 years of sales experience in the finishing industry, notably with Sames Kremlin equipment, both direct and through its distribution networks.

#automotive

3M's Robotic Paint Repair System Receives Innovation Award

The 3M Finesse-It Robotic Paint Repair System repairs paint defects on automobiles coming off the assembly line using data from an advanced vision system.

#automotive

SUR/FIN Session to Focus on PFAS, Chromium Plating and Automotive Supply Chain

Experts from the surface finishing industry, representatives from several automotive OEMs, and government officials will be part of a technical session at SUR/FIN on June 7, 2022 that will focus on the barriers and incentives associated with chromium plating in the automotive supply chain.

#nasf #regulation #surfin

ABB Robotics Unveils World’s First Robot-Painted Art Car

ABB’s new PixelPaint technology is demonstrated through the reproduction of complex artworks for an automotive exterior.

#automotive

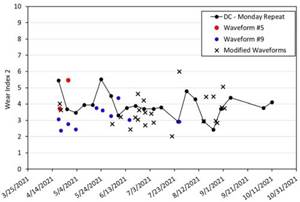

Improving the Wear Performance of Functional Trivalent Chromium Plating Via Pulse-Reverse Electrodeposition

This paper covers work on improving the wear performance of a functional chromium coating from a trivalent chromium plating bath. Wear resistance is a critical aspect of chromium coatings when used in components of both ground-based and aerospace vehicle systems. Traditional hexavalent chromium coatings have shown exceptional wear resistance in these applications, while the wear resistance of trivalent chromium coatings has been less satisfactory. Using pulse-reverse electrodeposition to control various characteristics of the chromium coating, the wear performance of trivalent chromium plated panels could be improved. A multivariate regression model of the electrodeposition conditions shows that bath chemistry parameters within the range of viable plating are not a large contributor to the variance in wear performance, while the roughness and size of macro-cracks is very important for wear-related applications. The multivariate analysis approach undertaken in this study may find potential applications in broad areas of the plating and finishing industry.

#aerospace #automotive #nasf

HMG Paints Expands Metallic Color Lineup

The company has added 70 metallic colors that are designed for industries such as commercial vehicle, agriculture and construction equipment, amongst others.

#automotive

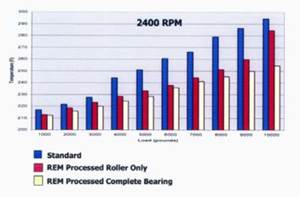

The Basics of Automotive Surface Engineering by Isotropic Superfinishing

This paper discusses using a non-abrasive, high density media in conjunction with an isotropic superfinishing (ISF) chemistry. This improved surface significantly reduces friction and provides several engineering advantages. The paper also reviews the technique used to generate ISF and some of the improvements that can be imparted to metal-to-metal contact surfaces.

#basics #nasf #surfin

Arkema Announces High Voltage Coating Solutions for Electric Vehicles

Arkema has introduced new advanced materials with UL certifications for busbar insulation.

#automotive

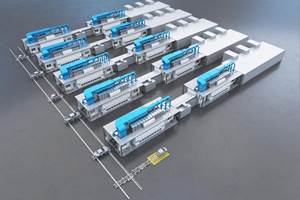

Dürr Launches Modular, Sustainable Spray Booth for Automotive

Dürr’s EcoProBooth boxes can transform individual painting lines into an efficient and flexible painting environment. The size and design of the box are standard, meaning straightforward conversions and extensions are possible without affecting production in other box segments.

#sustainability #automotive

Jeep Extends Limited-Run Paint Color

Recent Jeep Wrangler sales illustrate the importance of paint to vehicle sales.

#automotive