How to Create a ‘Frictionless’ Plating & Coating Supply Chain

Making an outside finishing vendor part of an integrated supply chain cuts costs for both parties and — even more importantly — enables increased throughput.

#basics

Understanding Paint Atomization

BASF coatings development expert Tim December explains how paint atomization works for both pneumatic spray applicators and high-speed rotary bell applicators.

#basics #ask the expert

Troubleshooting Bright Nickel Processes: How to Identify the Problem

For bright nickel process troubleshooting, Doug Lay of Coventya suggests narrowing the scope with a checklist.

#basics #ask the expert

Controlling Quality of Zinc Flake Coatings on Steel Fasteners

Scott McEuen, North American business development manager of zinc flake coatings at Atotech, explains how the quality of zinc flake coatings depends on good adhesion and bonding to the substrate of the fasteners.

#basics #ask the expert

How To Reduce Steps Required In Nonferrous Surface Finishing

The finishing of parts made from various copper and aluminum alloys traditionally require many distinct and separate process steps, and Hubbard-Hall’s Mike Valenti explains how both come with their own unique needs .

#ask the expert #basics

How To Reduce Steps Required In Nonferrous Surface Finishing

The finishing of parts made from various copper and aluminum alloys traditionally require many distinct and separate process steps, and Hubbard-Hall’s Mike Valenti explains how both come with their own unique needs .

#basics

Developments and Trends in Powder Coating

New solutions for powder coating centers combine powder preparation, conveyance, dosing and color changes into a fully automated, closed system.

#ask the expert #basics

Ultrasonic Cleaning Basics: Technology, Solvents and Advantages

Ultrasonic cleaning technology is explained here as well as how to choose a type of ultrasonic machine for an application, the kind of detergent to use, and the advantages of using this parts cleaning method.

#basics

Steps to Take Control of Wastewater Treatment

Finishing operations should consider their environmental impact and other motivating factors, beyond mere compliance.

#basics #pollution control #sustainability

How to Stop Powder Coatings from Drifting from Spray Booth

Nordson’s Frank Mohar says the main function of any powder booth is to contain excess powder overspray.

#ask the expert #basics

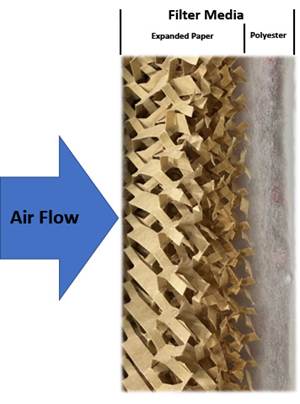

How to Know When to Change Spray Booth Filters

When it comes to determining when to change your spray booth filters, Trey Peavy from Col-Met Engineered Finishing Solutions says to first differentiate between intake filters and exhaust filters.

#ask the expert #basics

Understanding Compliance Inspection using the 6Ps Model

Staff from the City of Los Angeles Sanitation Department’s Bureau of Sanitation’s Industrial Waste Management Division, explain how metal finishers can utilize the 6Ps Model.

#regulation #basics #research

Maximizing the Service Life of Process Tanks

PVDF liners have a proven history with delivering end users longer lasting, lower maintenance plating tanks.

#basics

How to Measure Ecoat Throwpower in the Field

Axalta’s Dan Rose says the regular monitoring, recording and charting of throwpower can be a very valuable tool for ensuring quality.

#ask the expert #basics

When to Perform Vacuum Impregnation on Parts

Andy Marin from Godfrey and Wing says the general rule is that vacuum impregnation should be done before any surface finishes.

#vacuum-vapor #basics

Understanding Metallic Effect Powder Coatings

Metallic effect powder coating is a broad term, and Axalta’s Mike Withers says it usually covers powder coatings that have aluminum or mica pigments.

#basics

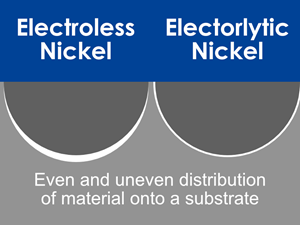

Electrolytic Versus Electroless Nickel Plating

Electroless and electrolytic nickel platings are effective at significantly improving a part’s strength and durability, but the differences between the two processes are important to distinguish.

#basics

How to Select the Right Heater for Your System

When selecting equipment to operate a process lines, Edward Dulzer from Process Technology says there is a wide variety of products to choose from.

#basics

How to Ensure Topcoat or Sealer Maintains Corrosion Resistance

Adam Blakeley with MacDermid Enthone Industrial Solutions says there are six crucial parameters for proper application of sealers.

#basics

How to Clean Parts Properly Before Powder Coating

Ken Kaluzny, from Coral Chemical, says that if mill oil is not removed from parts, you would observe pin holes and craters in the cured powder paint.

#basics