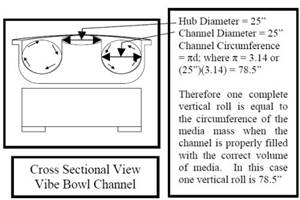

Calculating Applied Media Force During Vibratory Finishing

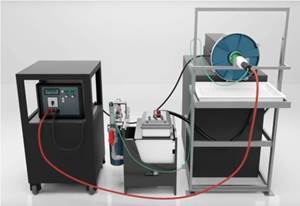

What appear to be identically set-up vibratory bowls will finish identical loads of parts in varying time cycles. This paper offers a new technique to better predict what the operator will produce, by measuring the force applied to the parts. It is the efficiency of that force which controls the efficiency and speed of the refinement cycle.

#surfin #research

Material Database Enables Coating Thickness Measurement Without Calibration

The database from Coatmaster AG has calibrations of over 400 different RAL colors.

#research #measurement-testing

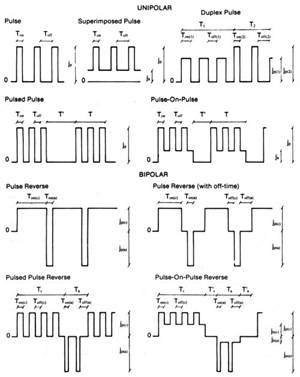

Qualitative Approach to Pulse Plating

In 1986, the AESF published Theory and Practice of Pulse Plating, edited by Jean Claude Puippe and Frank Leaman, the world’s first textbook on pulse plating. A compendium of chapters written by experts in this then-emerging field, the book quickly became the authoritative text in pulse plating. What follows here is the opening chapter, serving as an introduction to the field. Although the field has grown immensely in the intervening 35 years, the reader will find that the material remains a valuable introduction to those looking to advance the field of pulse plating.

#nasf #research

Enhancing the Corrosion Resistance of Electroless Nickel with TCP

Ronatec and CHEMEON have achieved promising early results for bolstering electroless nickel corrosion resistance through the application of a trivalent chromium pretreatment (TCP) top coat.

#research

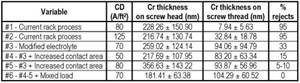

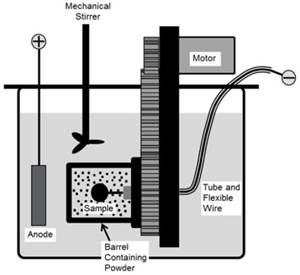

Decorative Trivalent Chromium Deposits Applied by Barrel Electroplating

With the wide acceptance of the benefits of decorative trivalent chromium plating, there is a growing demand to successfully adapt this technology to barrel plating. Traditionally, trivalent chromium deposits were not commercially viable using barrel electroplating. Factors such as barrel design, cathode contact, anode placement and current density must be considered when providing a trivalent chromium barrel electrodeposit. This presentation outlines trivalent deposits applied in a barrel and examines variables in operating and electrolyte compositions.

#surfin #research

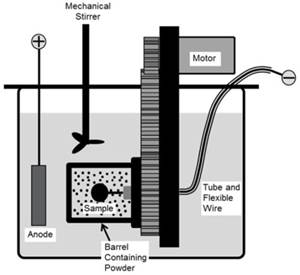

Electro-codeposition of MCrAlY Coatings for Advanced Gas Turbine Applications - 8th Quarterly Research Report

This NASF-AESF Foundation research project report covers the eighth quarter of project work (October-December 2019) on AESF Foundation Research at Tennessee Tech. The objective of the work is to study and optimize the MCrAlY electro-codeposition process to improve the coating oxidation/corrosion performance. In this quarter, the effects of particle density and shape on codeposition were studied. The results show that the shape of the particles plays an important role.

#research #nasf

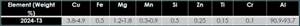

Correlation Between Electrochemical Behavior and Neutral Salt Fog Corrosion on TCP Coated AA2024

Differences in open circuit potential, electrochemical impedance spectroscopy and Tafel analysis were observed and quantified between the best- and worst-performing processes.

#research #surfin

Best Plating Practices for the Application of Brush Plated Zinc-Nickel

Brush plating is an industrial electroplating process designed for demanding OEM and repair applications, without the use of an immersion tank. This presentation demonstrates the best practices for brush plating zinc-nickel to meet the ASTM standards of hydrogen embrittlement and corrosion protection. From preparatory steps to the application of a trivalent chromium conversion coating, the proper plating techniques needed to meet the customers’ demanding requirements are discussed.

#surfin #research #regulation

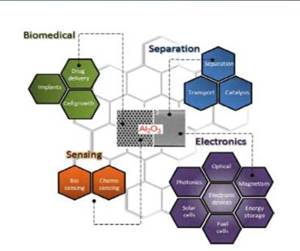

Nanostructure of Porous Anodic Aluminum Oxide: Advances in Surface Engineering

Porous alumina membranes of anodic aluminum oxide (AAO) are widely used for the fabrication of various nanostructures and nanodevices. Over the last decade, nanowires, nanotubes and nanodot arrays, have been fabricated by the deposition of various metals, semiconductors, oxides and polymers inside the pores of AAO membranes. These structures are produced by changing the anodization conditions, during electrochemically self -ordering of AAO. One can obtain amorphous barrier-type oxides, crystalline barrier-type oxides or amorphous nanoporous oxides, but fabricating binary nanostructures is challenging. Here, we review methods to achieve diverse binary nanostructure arrays, including material, dimension and morphology.

#research #surfin

Electrochemical Destruction of Perfluorooctanesulfonate in Electroplating Wastewaters - 1st & 2nd Quarterly Report

This is the first report on a new NASF-AESF Foundation research project dealing with PFAS - a critical issue for the surface finishing industry. The project will study an electrochemical, destructive treatment strategy for the remediation of relevant PFASs in electroplating wastewater. The overall objective is to utilize a cost-effective reactive electrochemical membrane (REM) for the removal of PFAS from synthetic electroplating wastewater.

#research #nasf

Improved Process Capabilities for Groove Repair

Advanced selective plating techniques have been developed for the challenging application of repairing internal grooves that have experienced severe corrosion. Many groove configurations require uniform, high-thickness deposition of a plated deposit onto any, or all, of the surfaces with a minimal need for intermediate machining steps. This paper demonstrates how a combination of an engineered, wrap-less anode design along with optimized computer controlled operating parameters has led to reduced downtime, high quality and repeatable selective plating repairs.

#research #surfin

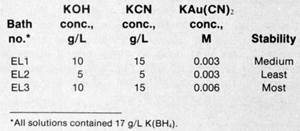

Laser-Induced Selective Deposition on Metal Using Electroless Gold

Originally published as H.R. Khan, M.U. Kittel and Ch. J. Raub, Plating and Surface Finishing, 75 (8), 58-64 (1988), this paper was awarded the 1989 AESF Gold Medal. The idea was to see if shining a laser on the substrate during electroless gold plating had any significant effect. The results are presented here.

#research

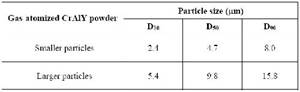

Electrocodeposition of MCrAlY Coatings for Advanced Gas Turbine Applications - 7th Quarterly Research Report

This NASF-AESF Foundation research project report covers the seventh quarter of project work (July-September 2019) on the AESF Foundation Research project at the Tennessee Technological University. The objective of the work is to study and optimize the MCrAlY electro-codeposition process to improve the coating oxidation/corrosion performance. In this quarter, the effect of the particle size of gas-atomized CrAlY powders on electro-codeposited Ni-CrAlY composite coatings was studied.

#research #nasf

Understanding Compliance Inspection using the 6Ps Model

Staff from the City of Los Angeles Sanitation Department’s Bureau of Sanitation’s Industrial Waste Management Division, explain how metal finishers can utilize the 6Ps Model.

#regulation #basics #research

Troubleshooting Chromium Conversion Coatings on Aluminum

This paper provides processors with an extensive troubleshooting tool when conversion coating failures are encountered.

#research #surfin

Electrocodeposition of MCrAlY Coatings for Advanced Gas Turbine Applications - 6th Quarterly Research Report

This NASF-AESF Foundation research project report covers the sixth quarter of project work (April-June 2019) on this AESF Foundation Research project at the Tennessee Technological University.

#research #nasf

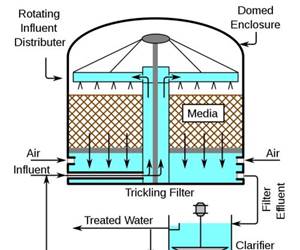

Biological Wastewater Treatment for Industrial Applications

With tightening limits on nutrients and Biological Oxygen Demand (BOD), is a small scale biological system right for your industrial facility?

#research #surfin

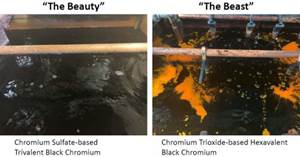

Black Chromium Finishing: Beauty and the Beast

Over the past 10 years, there has been commercial development of black chromium deposits from a trivalent chromium electrolyte. This paper will review the deposit characteristics and operational consideration of these similar, but different chromium plating deposits.

#research #surfin

An Improvement in the Zincate Method for Plating on Aluminum

Investigations were conducted into the sodium zincate solution used for treating aluminum prior to its being plated. Measurements of the adhesion of the nickel plate to aluminum and its alloys were done to check the effect of modifications made to this solution.

#research

Beyond Ni/Au: Next Generation Corrosion-Resistant Finishes for Electronics Applications

This paper describes several next-generation approaches to increasing the corrosion-resistance of electroplated articles using various methods in the search for finishes to replace the Ni/Au industry standard.

#research #electronics #surfin