Toward Automatic Control of Nickel Plating Processes

Technological advances in electronics manufacturing and the design of automobiles have brought about a trend toward very narrow specifications and increasingly stringent requirements on the quality of electrodeposited layers of nickel.

#research #surfin #electronics

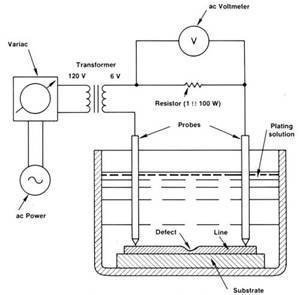

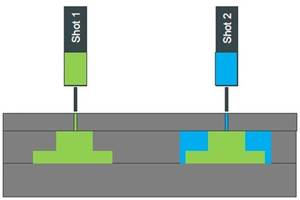

Self-Induced Repair of Printed Circuit Boards

This is a re-publication of the 1992 AESF Gold Medal Award paper for best paper published in Plating & Surface Finishing in 1991. It introduces a then-new technique for repairing near-opens (constrictions) in the wiring on printed circuit boards has been developed.

#research #electronics

Surface Finishing in the 2000s - As Predicted in 1992

In the December 1992 issue of Plating and Surface Finishing, a series of articles was published, predicting the future of the global surface finishing industry in the 21st century, then due to arrive in less than a decade.

#research #surfin

Impact of Intermetallic Species on Cast Aluminum Alloys for Anodizing Applications

Alloys with higher silicon concentrations can inhibit the growth of anodic oxide films under galvanostatic and potentiostatic conditions.

#research

The Relationship Between Vickers Hardness and Universal Hardness

The Vickers indenter hardness test, based on indenter displacement under test load (universal hardness), is being used for an increasing number of applications. The new method is also subject to much discussion among the experts. An important question is the relationship or the degree of correlation between the new universal hardness test and the classic Vickers hardness test.

#research

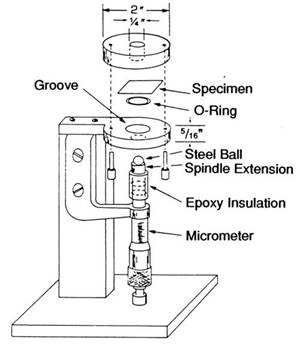

Evaluation of a Simple Thin-Film Ductility Tester and Review of the Ductility of Nickel Sulfamate Deposits

Originally published in 1992, this paper addressed a critical issue in the science of electroforming, that of the measurement and control of deposit ductility.

#research

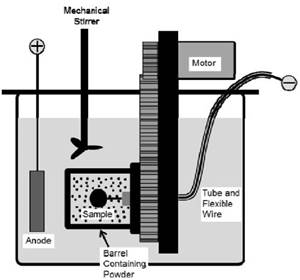

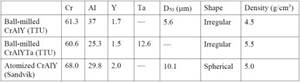

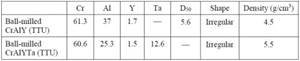

Electrocodeposition of MCrAlY Coatings for Advanced Gas Turbine Applications - 5th Quarterly Research Report

The objective of the work is to study and optimize the MCrAlY electrocodeposition process to improve the coating oxidation/corrosion performance. In this quarter, work focused on preparation and characterization of CrAlY-based alloy powders for the planned research activities in Task 2: The Effect of CrAlY Particle size on CrAlY Particle Incorporation.

#research

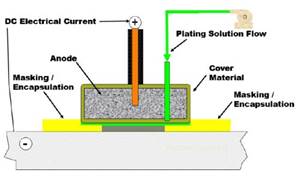

Advancements in Brush Plated Metal Matrix Composites

Finding safer, eco-friendly alternatives to hard chromium plating has been a main driver of brush electroplating research for the last decade.

#research #surfin

The Mechanism of Nickel Corrosion in ENEPIG Deposits and How to Mitigate It

The incident of nickel corrosion in ENEPIG multilayers (electroless nickel, electroless palladium and immersion gold) was brought to light after it was observed during the analysis of gold wire bond lifts.

#research #basics #surfin

Nanoporous Anodic Oxides: Fabrication, Applications, Sensing and Biosensing

Numerous metals are subjected to anodic oxidation. As a result, one can obtain amorphous barrier-type oxides, crystalline barrier-type oxides or amorphous nanoporous oxides. This paper provides details of sensing techniques and recent advances in the development of NAA-based sensing and biosensing technologies.

#surfin #research

Electro-codeposition of MCrAlY Coatings for Advanced Gas Turbine Applications - 4th Quarterly Research Report

This NASF-AESF Foundation research project report covers the fourth quarter of project work (October-December 2018) on this AESF Foundation Research project at the Tennessee Technological University.

#research #nasf

Phosphates: How They Impact Your Discharge

This presentation starts with an overview of the element phosphorus and its uses, which ultimately lead to eutrophication of our water supply.

#research #surfin #pollution control

Cyanide Destruction: A New Look at an Age-Old Problem

Cyanide in mining and industrial wastewaters has been around from the beginning, including electroplating processes. This presentation reviews a number of current processes, and in particular, offers new technologies for improvement in cyanide destruction by the most common process, using sodium hypochlorite.

#research #pollution control #surfin

Innovative, Hybrid Functional Coatings for Aluminum and Titanium Substrates

This paper describes a low cost alternative coating technology for light metals that electrodeposits an engineered thin-film coating which bonds tightly to the substrate and provides excellent corrosion and wear resistance along with superior electrical and thermal performance. As a new process, this technology offers a stable, low-cost option to manufacturers and applicators seeking to improve and extend their use of light metal substrates.

#research #surfin

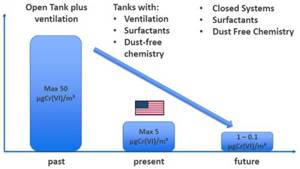

Technology Advancements for Select Key Hard Chromium Applications

This paper presents recent industry specific hard chromium technology advancements such as meeting the needs of the automotive and hydraulic industries. Examples for additional improvement potential are shown to simplify the operation and make hard chromium plating even more reliable in its specific needs for a wide range of industries served.

#research #surfin #automotive

Electro-codeposition of MCrAlY Coatings for Advanced Gas Turbine Applications - 3rd Quarterly Research Report

This NASF-AESF Foundation research project report covers the third quarter of project work (July-September 2018) on this AESF Foundation Research project at the Tennessee Technological University. The objective of the work is to study and optimize the MCrAlY electro-codeposition process to improve the coating oxidation/corrosion performance. In this quarter, studies continued on the effect of current density on CrAlY particle incorporation in electro-codeposited Ni-CrAlY composite coatings, focusing on the current density range of 20 to 60 mA/cm2.

#research #nasf

Is it Time to Revisit your Plastic Metallization Process?

The plating on plastics (POP) market has evolved to include an ever-broader range of substrates, huge increases in selective plating demand, using tools such as two-shot molding and laser ablation.

#research #economics #surfin

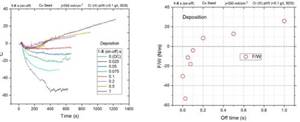

Crack Formation during Electrodeposition and Post-deposition Aging of Thin Film Coatings - 9th & 10th Quarterly Report

This NASF-AESF Foundation research project report covers the ninth and tenth quarters of project work (January-June 2018) on this AESF Foundation Research project at the University of Houston. The work continued towards identifying the effective pulse deposition approach to control and mitigate the stress state of chromium thin films and also involved a comprehensive study of palladium stress evolution during electrodeposition and strategies to mitigate its magnitude.

#research #nasf

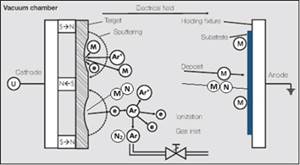

Advances in Decorative PVD Chromium Coatings for Polymer Substrates

This article reviews a two-layer, selective coating process which incorporates a specially developed UV-cured paint base coating with a sub-micron thick PVD chromium top coating. It illustrates the coating’s testing protocols of automotive manufacturers and the necessities of controlling the stresses within the coating matrix.

#research #vacuum-vapor #surfin

Electro-codeposition of MCrAlY Coatings for Advanced Gas Turbine Applications - 2nd Quarterly Research Report

In this quarter, focus was on planned research on the effect of current density and powder density on CrAlY(Ta) particle incorporation in electro-codeposited Ni-CrAlY(Ta) composite coatings.

#research