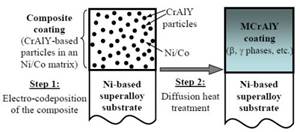

Electro-codeposition of MCrAlY Coatings for Advanced Gas Turbine Applications - 1st Quarterly Research Report

This first year of work involves the effect of operating parameters on the CrAlY particle incorporation in the coating.

#research

Innovative Applications of Electroplating and PVD for New Material Solutions - The 54th William Blum Lecture

The following is Dr. Per Møller’s William Blum Memorial Lecture at SUR/FIN 2018, in Cleveland, Ohio on June 4, 2018, with commentary by NASF Technical Editor James H. Lindsay. It covers a variety of projects involved with surface finishing applications, including sustainable energy. Due to Dr. Møller’s serious illness, he was unable to make the journey to SUR/FIN. In his stead, his longtime professional colleague, Dr. Lars Pleth Nielsen, of the Danish Technological Institute (DTI), presented the lecture.

#research #surfin #vacuum-vapor

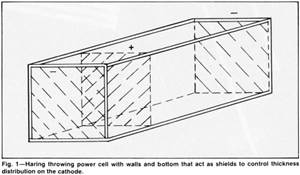

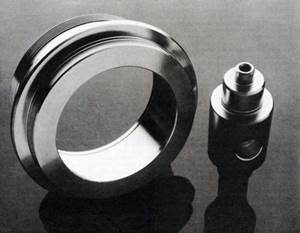

III. The Effects of Shields and Baffles on the Distribution of Functional Chromium Electrodeposits

This is the third of three combined papers that received the AESF Gold Medal Award for Best Paper published in Plating & Surface Finishing in 1989. Insulating shields and baffles redirect the flow of current and affect the thickness distribution of chromium and other electrodeposits. Many examples of these useful devices for improving the uniformity of chromium deposits are described.

#research #surfin

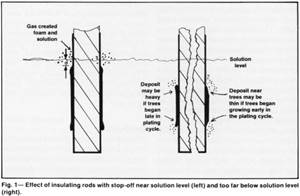

II. The Effects of Stopoffs and Thieves on the Distribution of Functional Chromium Electrodeposits

This is the second of three combined papers that received the AESF Gold Medal Award for Best Paper published in Plating & Surface Finishing in 1989. Stop-offs, thieves and guards are used to change the pattern of current flow and improve metal distribution. The effects may be planned or may occur unexpectedly, producing undesirable results.

#research #surfin

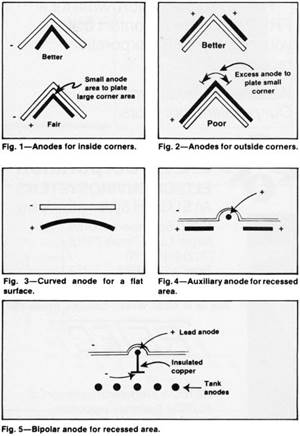

I. Rack and Anode Effects on the Distribution of Functional Chromium Electrodeposits

This is the first of three combined papers that received the AESF Gold Medal Award for Best Paper published in Plating & Surface Finishing in 1989. Procedures for improving functional chromium thickness distribution begin with this paper that advocates useful rack designs and anode configurations.

#research #surfin

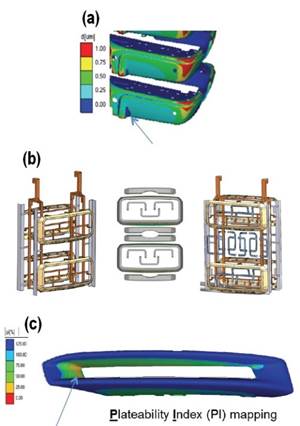

Acid Copper Technologies for Plating on Plastics

Automotive OEM performance requirements continue to increase which presents increased challenges to the supply chain to provide acceptable parts. This presentation will introduce a new system of acid copper technologies that have been designed to increase performance, widen the process operating window, reduce rejects and ultimately increase production capacity.

#surfin #research #automotive

Transition from a Simple Auxiliary Anode to a Fully-developed Conforming Anode System for Plating

This paper demonstrates that the use of an elaborate CAE designed conforming anode system enables plating complex exterior automotive part designs within specification. It will be shown that the increased fixed and variable production costs that are unavoidable when operating an elaborate conforming anode system can be partially earned back by a reduction in metal consumption, and by an increased capacity due to shorter plating times.

#research #surfin #automotive

Historical Highlights of Electroless Plating

In a 1984 article in Plating and Surface Finishing, for the AESF 75th anniversary year, Charles R. Shipley Jr. recounts the history of the commercialization of electroless plating beyond the discovery of electroless nickel by Dr. Abner Brenner and Grace Riddell at the National Bureau of Standards.

#research

Reminiscences of Early Electroless Plating

The development of autocatalytic deposition was one of the most important developments in the history of surface finishing. Here, in an article from Plating and Surface Finishing in 1984, the AESF 75th anniversary year, Dr. Abner Brenner, considered to be the “Father of Electroless Plating,” recalls why and how it came about.

#research #surfin

Crack Formation during Electrodeposition and Post-deposition Aging of Thin Film Coatings - 7th & 8th Quarterly Report

This NASF-AESF Foundation research project report covers the seventh and eighth quarters of project work (July-December 2017) on this AESF Foundation Research project at the University of Houston. The objective of the work is to study fundamental and practical aspects of crack formation in electrodeposited thin films.

#research #nasf

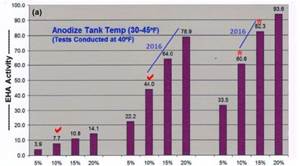

New Selective Brush / Cell Anodizing Technology Using Sulfuric / Organic Mixed Electrolytes for Dimensional Restoration of Difficult Alloys

This paper presents new innovative problem-solving technology for Type I, II and III selective brush and repair cell anodizing. Discussions include: (1) anodizing difficult alloys (2000/7000 series) without burning; (2) unique amino complex organic acid protection of the aluminum/anodize surface during processing and (3) high speed anodizing in selective cell operations, including heavy thickness anodize repair procedures.

#research #surfin

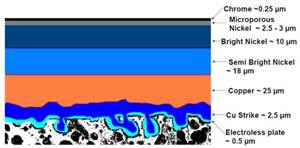

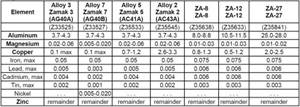

Special Aspects of Electrodeposition on Zinc Die Castings

Electroplating is a frequent choice to give zinc die cast components a high-quality protective and decorative surface finish, however, applying this kind of treatment for die cast zinc components presents hidden challenges. In order to overcome these issues, a thorough morphology and composition analysis of die cast items was conducted. Special aspects of zinc die cast as a plating substrate are described and linked to the die casting process.

#research

Electroless Nickel Coatings: Appearance, Gloss and Surface Morphology

For decorative coatings, appearance is the essential purpose for application, but also for functional surface finishes it becomes increasingly relevant as an added value on top of specified technical requirements. Appearance is affected by spectrum and intensity of incident light, roughness and morphology of the coating surface, optical properties of the coating material, eventual superficial oxide films, and individual perception. The predominant factor is surface roughness, which in turn depends on base material roughness, quality of substrate pretreatment, and nucleation and growth kinetics of the electroless nickel (EN) deposit. Interdependency of gloss measurements with roughness measurements and with chemical composition of coatings was investigated for new generation mid-P EN processes and compared to traditional ones.

#surfin #research

Nanostructures by Anodization of Alumina in Phosphoric Acid at Low Potential

Anodic aluminum oxide (AAO) has been investigated, in terms of influence of the process time, anodizing potential and methanol addition on the structural features of porous anodic alumina formed in 0.1M H3PO4 solution by two-step self-organized anodizing for potentials ranging from 100-150 V. The structural features of the porous structures, including pore diameter and interpore distance, were evaluated from FE-SEM top-view images for samples anodized in the presence and absence of methanol.

#research #surfin

Additive Manufacturing and Surface Finishing - The 53rd William Blum Lecture

This presentation is the 53rd William Blum Lecture, presented at SUR/FIN 2016 in Las Vegas, Nevada on June 6, 2016. In this lecture, Dr. Melissa Klingenberg discusses additive manufacturing; that is, any manufacturing process capable of making 3D objects from a digital model, or building-up 3D features onto an existing object, layer-by-layer. Cold spray, thermal spray, electroforming, structural plating and gaseous carbonyl deposition are covered.

#research #additive-manufacturing #surfin

Nickel: Science, Health and the Future - The 52nd William Blum Lecture

This presentation is the 52nd William Blum Lecture, presented at SUR/FIN 2015 in Rosemont, Illinois on June 8, 2015. In this lecture, Dr. Hudson Bates discusses the nickel research in his group at the Nickel Producers Environmental Research Association (NiPERA), which impact occupational health and environmental issues for nickel. This includes nano-particulates, toxicity of mixtures, ambient air effects, and providing good science in regulatory matters.

#surfin #research #medical

Surface Finishing Sustainability: Technology Pathways - The 51st William Blum Lecture

This presentation is the 51st William Blum Lecture, presented at SUR/FIN 2014 in Cleveland, Ohio on June 9, 2014. In this lecture, Dr. Yinlun Huang discusses the critical issue of sustainability in manufacturing with the primary focus on the surface finishing industry, and the technology directed toward addressing the issue.

#research #surfin #sustainability

Decorative Electroplating: Theory to Explain Rapid Corrosion Due to Calcium Chloride ‘Russian Mud’ - The 48th William Blum Lecture

This presentation is the 48th William Blum Lecture, presented at SUR/FIN 2010 in Grand Rapids, Michigan on June 14, 2010. In this lecture, Dr. Donald Snyder describes the phenomena behind a new challenge to decorative Cu-Ni-Cr plating, catastrophic corrosion failures involving the use of calcium chloride on Russian highways

#research #surfin

Electrodeposited Inconel and Stellite-like Coatings for Improved Corrosion Resistance in Biocombustors

This work deals with problems in the Third World – namely improving the safety and efficiency of cookstoves used by people around the world. A scalable and economic process is required to apply coatings on low-cost stainless steel substrates for enhanced high temperature corrosion resistance specifically targeted towards biomass combustion apparatus. Cost effective, scalable, and flexible electrodeposition-based coating of various alloys [Ni/Co]-Cr-[Mo/Fe] system, that are able to withstand high temperature corrosion and improve the functional lifetime of existing and next generation bio-combustors components is a desirable technological advancement. Within this context, a wide array of electrolytes and processing parameters were evaluated to develop an ideal alloy coating.

#research #surfin

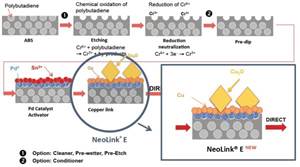

Direct Metallization for Plating on Plastics

A new combination of copper immersion and autocatalytic copper-(I)-oxide deposition enables lower palladium concentrations in the activator bath, though the amount of copper deposited on the plastic surface can be up to ten times higher compared to its predecessor processes.

#surfin #research