Vacuum Degreaser Cleans Up a Messy Situation

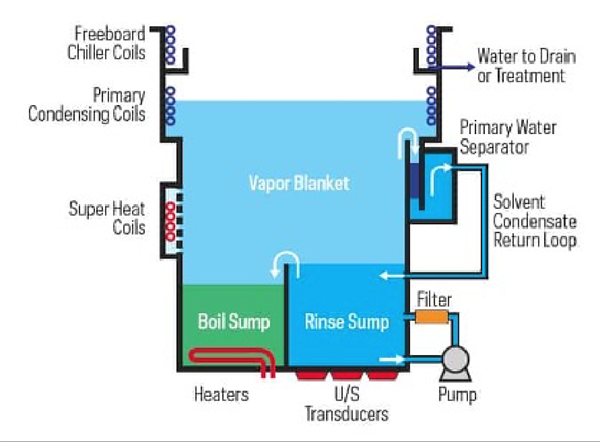

By replacing its immersion parts washer with a vacuum degreasing system, this machine shop is much more efficient, saving the company money, man hours and the health of the operators.

Lori Beckman

Senior Editor, Products Finishing

Top Shop Emphasizes Dedication, Work Ethic

With a primary focus on aerospace and defense work, American Metaseal Corp. of Arbutus, Maryland, has qualified as a Top Shop on multiple occasions.

MicroCare Offers Alternatives to Discontinued Vapor Degreasing Fluids

MicroCare says it is equipped to handle customers affected by 3M's discontinuation of the Novec specialty fluids line with its own products.

Solar Atmospheres of Western PA Receives Nadcap Accreditation

The company received the accreditation for it’s new, fully integrated Vacuum Oil Quench furnace, which provides a significantly cleaner and safer oil quenching process.

Umicore Combines Electroplating, Thin Film Business

The company’s new Metal Deposition Solutions business unit combines the former Electroplating and Thin Film Products business lines.

Exair's Threaded Line Vac Transports Abrasive Materials

Exair’s Heavy Duty Threaded Line Vacs are made of a hardened alloy to prevent premature wear when transporting abrasive or heavy materials like garnet, glass, sand, shot blast, tumbling media or metal fittings.

Hartzell Air Movement Showcases Its Line of Fiberglass Fans

At SUR/FIN 2021, Hartzell Air Movement will showcase its line of fiberglass fans, which the company recommends for situations where corrosive elements exist in fume or in vapor form.