Solvent Kleene Releases Extreme Heat Resistant Powder Coating Remover

Solvent Kleene’s D-Zolve 917 facilitates the removal of extreme temperature resistant and chemical resistant powder coating.

Edited by Scott Francis

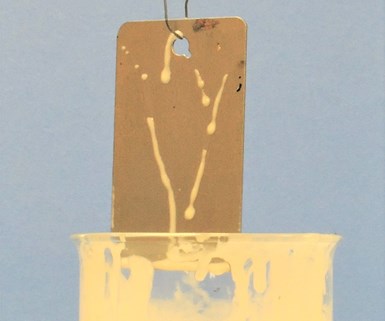

Before immersion in D-Zolve 917. Source | Solvent Kleene Inc.

Solvent Kleene Inc. (Peabody, Mass.) has released D-Zolve 917, a product designed to remove extreme temperature resistant and chemical resistant powder coating.

Extreme heat and chemical resistant powder coating is used in applications where it is important the coating withstand extreme temperatures without discoloring, losing gloss, adhesion or cracking. Because it has greater durability than ceramic coating and has been tested in temperatures up to 1200°F/ 649°C, removing chemical resistant high temperature powder coating can be challenging.

After immersion in D-Zolve 917.

D-Zolve 917 removes the powder coating from the surface of the substrate. The solution performs at low temperature of 110°F., is non-flammable, contains no methylene chloride or peroxides. The high temperature powder coating is removed by immersion with agitation followed by a quick water rinse.

Solvent Kleene Inc. | 978-531-2279 | solventkleene.com

RELATED CONTENT

-

Coating Systems with the Best Long-Term Performance

The best protection against corrosion and UV exposure, says Axalta’s Mike Withers, is electrocoat and a super durable powder coating.

-

Calculating Oven Heat Load Capacity

Please explain how to calculate the heat load capacity of a paint baking oven, using aluminum alloy wheels as an example.

-

Removing Cured Powder Coatings

Question: What methods are available for removing cured powder coatings, and what are the pros and cons of these methods?