UK Auto’s 2020 Top Paint Color Is Grey

Head of the top automotive industry association calls 2020 a “pretty dark year.” Paint choices substantiate that.

#automotive

Let’s face it: our environment affects our moods and our moods affect our buying habit. 2020 in the United Kingdom (UK) had a decidedly dour environment, as COVID-19 hit the nation exceedingly hard.

So it isn’t at all surprising that the favorite new car color (or colour) in the UK in 2020 was … grey.

That according to the industry trade group, the Society of Motor Manufacturers and Traders (SMMT).

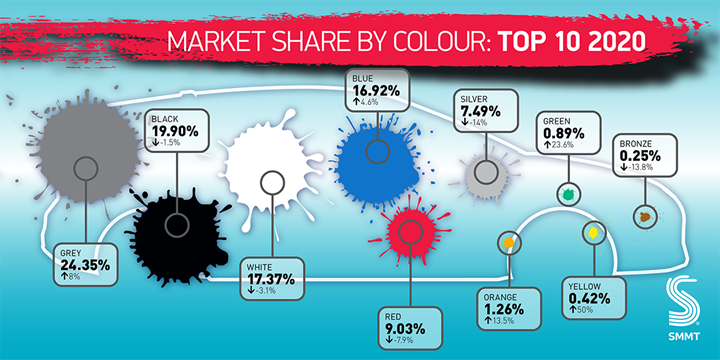

Paint colors for light vehicles in the UK in 2020 are decidedly monochromatic. (Image: SMMT)

Grey was the color choice for 24.3% of the vehicles sold in the UK last year—and sales-wise it was a grey year, as compared to 2019, as registrations were down 29.4%, for a total of 1.63-million vehicles, the worst year since 1992, when the number of vehicles registered was 1.594 million. (It wasn’t all COVID related, however: the anticipation of Breixt in some form or another played a role, as well.)

Rounding out the top three were black at 19.9% and white at 17.37%.

Admitted Mike Hawes, SMMT chief executive, “2020 was a pretty dark year for the automotive industry and having grey as the top new car color probably reflects the atmosphere.”

It is worth noting, however, that while yellow is the ninth color in the top 10 with a mere 0.42% of the market, it had the biggest rise: 50%.

So maybe there are sunnier times ahead in the UK.

RELATED CONTENT

-

Coating Thickness Measurement: The Fundamentals

A review of available test methods, common applications and innovative instrumentation...

-

Understanding Paint Atomization

BASF coatings development expert Tim December explains how paint atomization works for both pneumatic spray applicators and high-speed rotary bell applicators.

-

Is Your Electroplating Waste Hazardous?

Some that bears precious metals is, and there are a host of regulations to consider when recycling.

.jpg;width=70;height=70;mode=crop)