Vertical Aerospace used Plyable to go from CAD to first flight in less than 90 days

Composite tooling specialist’s online portal, distributed manufacturing network and automated tool design helped optimize CFRP molding tools and timeline.

Vertical Aerospace (Bristol, U.K.) was launched in 2016 with the vision of decarbonizing air travel using the best technology from the aviation, energy and automotive industries. The company flew its first electric vertical take-off and landing (eVTOL) aircraft in 2018, to demonstrate feasibility. Vertical then set about designing and building an eVTOL aircraft capable of carrying loads of up to 250 kilograms and reaching speeds of up to 80 kilometers per hour. They named it Seraph.

Aerospace production quality at prototyping speed

Aiming to release Seraph rapidly ahead of competitors, Vertical wanted to design and manufacture the aircraft on ambitious timescales and needed suppliers who could do the same. Ever greater focus on the aerospace industry’s carbon footprint makes lightweighting an absolute necessity. This meant Vertical’s Seraph aircraft could only be constructed from lightweight carbon fiber-reinforced plastic (CFRP) composites. However, it needed to make CFRP prototypes quickly, which in turn, required tooling. Vertical turned to composite tooling specialist Plyable (Oxford, U.K.) and its on-demand online portal.

“Getting high fidelity quotes from Plyable instantly on their online portal was really critical to validating our design decisions,” said Steven Baxter, head of programs at Vertical Aerospace. Vertical uploaded the project’s component files through the online portal, received a single consolidated quote and set their tooling lead time. Plyable’s online automated tool design technology then designed and optimized all the tools for the Seraph’s composite components. A joint design consultation, led by Plyable lead engineer Adam England, was only required to discuss final details before production began just two days later.

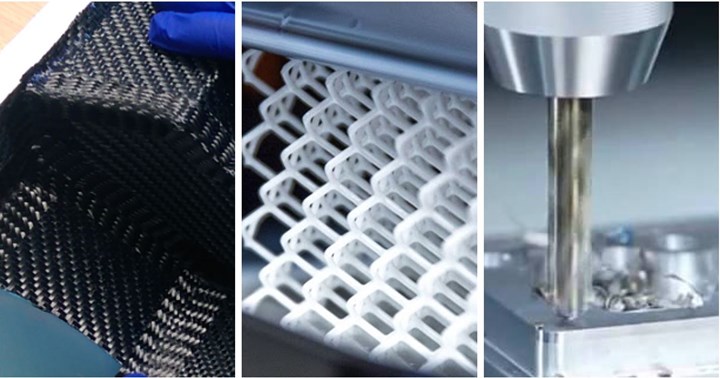

Plyable offers a wide range of tooling materials, including CFRP, 3D-printed polymer and machined metal. Source | Plyable

Plyable manufactured all of the tools in parallel using their distributed manufacturing network. “Our large capacity network was a key enabler in hitting the tight deadlines required and allowed Seraph to fly just 90 days from CAD first being uploaded,” notes England.

“Plyable’s online automated tool design technology saved weeks of engineering time and their capacity to manufacture simultaneously was remarkable,” said Baxter. “It really wouldn’t have been possible with the traditional manufacturing channels we’ve worked with before. I was impressed by the pace enabling us to get to first flight quickly.”

“Accelerating manufacturing and helping innovative companies like Vertical Aerospace bring their ideas to life is what Plyable is all about,” said Plyable CEO Martin Oughton. “We’re proud to see what Vertical has achieved with Seraph and advancements they will continue to achieve with new models.”

In 2019, Vertical Aerospace became the first company in the world to release footage of an actual eVTOL aircraft flying that can achieve a 250-kilogram payload and 80 kmph speed. Their next model is expected in 2020 and will look substantially different. It is planned to be the first version of the aircraft they will take forward to certification and will include a pilot, four passengers, wings and room for luggage.

Source | Vertical Aerospace

RELATED CONTENT

-

Dürr Partnership Expands Market Access for EV Batteries

The Dürr Group and Osaka-based firm Techno Smart have partnered to increase EV battery production efficiency. The Dürr Group is also expanding its small-factor battery production tech business and contributing to EV production across multiple departments.

-

Coatings Drive Electric Vehicles Further

Electric vehicle batteries depend on coatings to maintain optimal temperatures, reduce the risk of fire damage and electrical interference, and more.

-

Building an E-coat Line from the Ground Up

How one company is prospering by providing flexible e-coat capability to Nissan and other customers.