Videos: 40 Under 40 Class of 2024

In these uncertain times, it is refreshing to hear from and learn about young talent in the surface finishing industry who are striving to make a difference within their organizations and the industry as a whole.

#workforce development #40-under-40

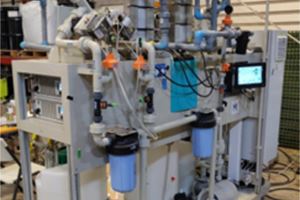

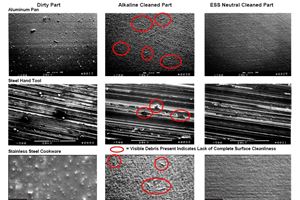

TTX Environmental Solves Customer Issue with Electro-Ceramic Desalination Wastewater Processing

Electroplating facility without access to a drainage system found a safe solution for wastewater treatment and reuse.