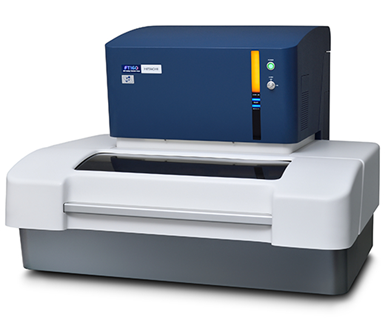

Hitachi FT160 XRF Analyzes Ultrathin Coatings

Benchtop unit designed for high sample throughput for quality control.

Hitachi FT160 XRF analyzer

Hitachi High-Tech Analytical Science’s FT160 XRF analyzer has three base configurations for analyzing nanometer-scale coatings on small features. The unit is a benchtop energy dispersive X-ray fluorescence analyzer designed to deliver high sample throughput with a wide range of applications in the semiconductor, circuit board and electronics components markets. According to the company, a polycapillary optic focuses the X-ray beam down to a diameter of <30 µm, focusing more intensity on the sample and measuring features smaller than what is possible with traditional collimation. It is said that a high-precision stage and high-definition camera with digital zoom allow for quick positioning of the sample features to improve sample throughput.

RELATED CONTENT

-

Zinc Electroplating

Choosing the best process for your operation.

-

Cleaning, Pretreatment to Meet Medical Specs ISO 13485 or FDA 21 CFR820

Maximilian Kessler from SurTec explains new practices for industrial parts cleaning, metal pretreatment and decorative electroplating in the medical device industry.

-

Plating Q&A: Can you color stainless steel?

Our expert, Art Kushner, says yes, you can color stainless steel, but it is not a process that is typically performed in a plating shop. Read more about his answer.