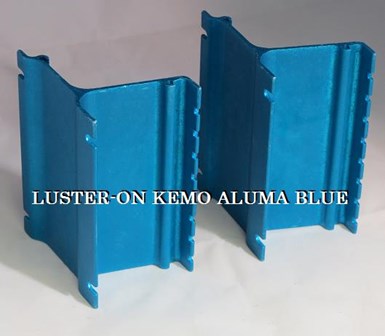

Luster-On Conversion Coatings Protect Aluminum

Luster-On Aluminescent is manufactured in powder form to provide economical and easy-to-use product.

#surfin

Luster-On Products’ Aluminescent conversion coating for aluminum is compliant for REACH, RoHS, WEEE and ELV, and approved for MIL-DTL-5541F. According to the company, it is manufactured in powder form to provide the most economical and easy-to-use product, which reduces shipping costs, minimizes storage requirements and simplifies bath additions.

The Aluminescent product line also includes the Aluminescent TX, a thixotropic formulation for field repair, and Aluminescent LQ, a liquid version of the maintenance-friendly powder. The company says that using Aluminescent protects aluminum parts and ensures superior adhesion of paints and adhesives.

Luster-On Products | 800-888-2541 | luster-on.com

RELATED CONTENT

-

Zinc Electroplating

Choosing the best process for your operation.

-

Aluminum Anodizing

Types of anodizing, processes, equipment selection and tank construction.

-

Cleaning, Pretreatment to Meet Medical Specs ISO 13485 or FDA 21 CFR820

Maximilian Kessler from SurTec explains new practices for industrial parts cleaning, metal pretreatment and decorative electroplating in the medical device industry.