Sherwin-Williams Launches Powdura ECO Coatings Using Recycled Plastic

Sherwin-Williams has launched a line of powder coatings that uses a polyester resin comprised of 25% pre-consumer recycled plastic (rPET).

#sustainability

Edited by Jenny Rush

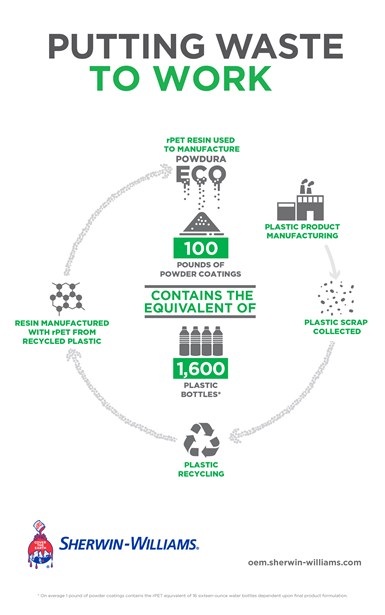

The General Industrial Division of Sherwin-Williams (Minneapolis, Minnesota) launched its first set of products from its Powdura ECO platform – the first and only line of powder coatings that uses a polyester resin comprised of 25% pre-consumer recycled plastic (rPET). According to Sherwin-Williams, Powdura ECO powder coatings promote sustainability throughout the supply chain and help reduce plastic pollution.

The company states that the product line is designed to help address the ever-growing concern of plastic pollution and sustainability. Powdura ECO coatings enable manufacturers to differentiate their finished goods with recycled materials that don’t compromise performance, according to Sherwin-Williams. Each pound of TGIC and TGIC-free Powdura ECO coatings contains the equivalent of 16 sixteen-ounce recycled plastic bottles. Sherwin-Williams states that Powdura ECO products meet or exceed existing powder coating performance standards.

According to Sherwin-Williams, Powdura ECO coatings are suitable for interior and exterior environments, and various applications including lawn equipment, transportation vehicles, consumer goods, electrical enclosures and fixtures. Powdura ECO coatings can also be customized to meet specification requirements. The company states that these coatings provide color retention and solvent resistance and may offer increased flexibility and impact resistance.

Available in a wide range of special effects, color and gloss options, Powdura ECO products are designed to be easy to apply, have wide cure capability, and offer light and weather fastness. They can also align with third-party certifications that define and measure sustainability standards, such as LEED, GreenGuard and BIFMA Level.

Sherwin-Williams | oem.sherwin-williams.comRELATED CONTENT

-

Developments and Trends in Powder Coating

New solutions for powder coating centers combine powder preparation, conveyance, dosing and color changes into a fully automated, closed system.

-

The Powder Coating Process

Powder coating is one of the most durable finishes that can be applied to industrial manufactured products, and offers excellent corrosion protection and is very safe because of its lack of volatile organic compounds. To understand the powder coating process you should start with the fundamentals.

-

Touch-up Options for Powder Coated Parts

Is it true that powder coating cannot be touched up? Powder coating expert Rodger Talbert offers options for powder coating touch-ups.