Columbia Chemical and Alufinish Announce Collaboration

By combining their sales and service capabilities and resources for the U.S. market, the two companies will cover the entire aluminum alloy surface treatment process from pre-treatment to anodizing and coating.

#economics

Product Finishing’s 2024 Top Shops Benchmarking Survey Deadline Approaches

Taking this year’s Products Finishing’s annual Top Shops Benchmarking Survey? Respondents are urged to complete the survey by April 30, 2024 in order to be considered as a qualifying top shop.

#Top Shops

BIM Files for Lorin’s Finishes Available for Direct Download

Access BIM files for anodized aluminum colors and finishes on Lorin’s website.

10 Anodizing Best Practices

Following this list of guidelines can help to increase the performance, cost effectiveness and quality for your anodizing operation.

#ask the expert

Top Shop Aces Outstanding Customer Service

More than a finishing shop, this anodizing, powder coating and vacuum resin impregnating business goes above and beyond for its customers by being a resource for whatever their finishing needs might demand.

#Top Shops

NADCAP Shop Digitizes to Eliminate Paper Trail

Customizable ERP software has transformed a 27-year-old manual metal finishing job shop into a state-of-the-art paperless company with full digital traceability in about 10 months.

#aerospace #military

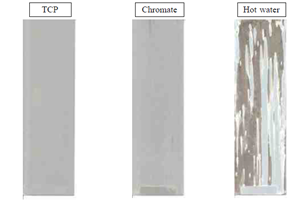

A Smooth Transition from One Anodizing Process to Another

Knowing when to switch from chromic acid anodizing to thin film sulfuric acid anodizing is important. Learn about why the change should be considered and the challenges in doing so.

#aerospace

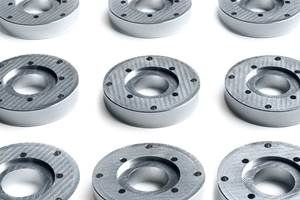

Protolabs Expands CNC Capabilities, Accelerates Anodizing, Chrome Plating

Expanded CNC machining capabilities enable product developers and production buyers to obtain custom-plated parts in as fast as four days.

Pulling Out All the Stops

Evolving coatings and finishes for automotive brake components.

#automotive

Trivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

#ask the expert #regulation #sustainability