Boosting the Power of Immersion Degreasing

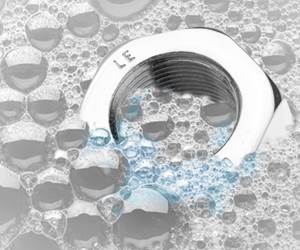

How do you make your parts cleaning operation more efficient? Add agitation, says Bex’s Steve Phillips.

Solution Removes Metalworking Oils, Inhibits Rust

Kyzen’s Metalnox M6324CP is a heavy-duty alkaline cleaner can remove difficult soils including carbon smut and chlorinated oils.

pH-Neutral Activator Removes Rust, Oxide Films

SurTec 414 cleans ferrous metals and aluminum as effectively as mineral acids.

Guide Helps Plan for New Equipment

Cleaning Technologies Group’s free “Planning for New Cleaning Equipment” guide is designed to help engineers and purchasing managers select the right parts cleaning equipment and then prepare to integrate that equipment in their processes and facilities.

A Look at Parts Cleaning Across the Continents

A visit to the parts2clean show examines how manufacturing views parts cleaning.

Chemical-Resistant Canopy Hoods Capture Fumes

Hemco manufactures a variety of canopy hoods designed to capture and exhaust fumes or steam that are corrosive, heated or of a noxious odor.

#pollutioncontrol

Water-based Shop Primer Inhibits Rust on Steel Surfaces

PPG’s Aquacron 834 is a water-based industrial shop primer designed to inhibit rust in steel applications.

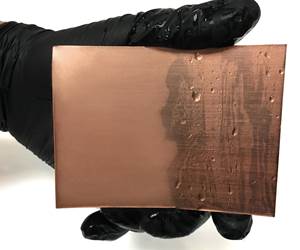

Pretreatment Leads to Water-break-free Plating Surfaces

Asterion provides customized soak, spray and electrocleaning process solutions designed for cost-effective and fast removal of soils and contaminants from steel, copper alloys, zinc die cast and other substrates.

Solution Removes Metalworking Oils, Inhibits Rust

Kyzen’s Metalnox M6324CP is a heavy-duty alkaline cleaner and inhibitor formulated to remove paraffinic oils used in a range of machining, stamping and deep-draw operations, and provide long-term protection from rust.

When to Discard Solution, Recharge a Parts Washer

How can we determine the ideal time to discard the cleaning solution and recharge these washers? Chemetall’s David Gotoff answers this question.

#basics