Seacole Specialty Chemical CEO Gregg Elliott Interviewed in Enterprise Minnesota Magazine

Seacole Specialty Chemical CEO Gregg Elliott was recently featured in the Fall 2022 edition of Enterprise Minnesota magazine. In the interview, Elliott discussed the effect of the pandemic-era economy on manufacturing and how small and medium-sized manufacturers are preparing for a potential recession.

Curing Ecoat at Lower Temperatures

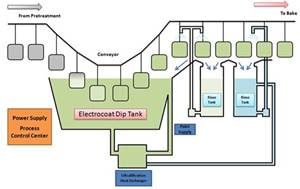

Recent innovations in ecoat technology allow for an expanded bake window to enable the curing of diverse substrates of varying thicknesses.

BASF Advancing E-Coat Applications

Although their e-coatings have been deployed millions of times, BASF Coatings is still learning more.

Ecoat — An Entrepreneurial Approach

Job shop style approach for a captive ecoat line encourages ownership, innovation.

#automotive

Caplugs Acquires Safeplast to Expand Solutions for Hose Protection

Caplugs acquires Safeplast as part of the company's efforts to expand hose protection capabilities.

#masking

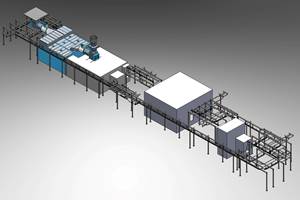

Statesville N.C. Start-Up Offers Turnkey Industrial Finishing Systems

United Finishing Systems LLC offers custom turnkey finishing solutions for electrocoating, powder coating and liquid coating.

FABTECH 2022 Returns to Atlanta

Discover the latest finishing technologies and connect with industry experts at FABTECH in Atlanta, Ga. November 8-10.

Coating Systems with the Best Long-Term Performance

The best protection against corrosion and UV exposure, says Axalta’s Mike Withers, is electrocoat and a super durable powder coating.

#ask the expert #basics

The Electrocoat Association Opens Registration for Webinar

The Electrocoat Association continues its Finisher’s Guide to Electrocoat webinar series with “Advanced Pretreatment" on November 15

#education

The Electrocoat Association Announces 2022 ECOAT Boot Camp

Register now for the 2022 ECOAT Boot Camp