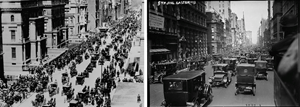

The History of Electroplating and A Historical Review of the Evolution of NASF

The history of electroplating is a curious mixture of mistakes, observations, serendipity and experimental development, enmeshed and entwined with the discovery of electricity in the late 18th century. Join Mr. Nebiolo as he reviews the fascinating history of our industry and its metamorphosis during the last 238 years. He will also provide a brief history of our flagship society, the NASF.

#nasf #surfin

MKS Instruments Acquires Atotech

The acquistion positions MKS to advance electronic device miniaturization and complexity, as well as extend product offerings for industrial applications.

#electronics

Silver-graphite Coating Fulfills Technical Requirements

Graphite particles mixed into the silver layer of this coating promote great abrasion resistance at maximum loading performance.

Achieving Coefficient of Friction Targets

Jennifer Geesey of Pavco Inc. offers advice for obtaining your desired coefficient of friction.

#asktheexpert

Registration Opens for NASF's Online Zinc & Zinc Alloy Course

The goal of the course is to provide participants with information related to the metallurgy and corrosion behavior of zinc coatings.

#nasf

Episode 23: An Interview With Brad Durkin, technical director for the Electroless Nickel Conference 2022

Electroless Nickel Conference 2022 will take place October 11-13 at the Omni Severin in Indianapolis, Indiana. Learn more about the event in this interview with ENC22 technical director Brad Durkin.

Disruptive Change: EVs and Finishing Opportunities

As EVs continue to claim an increasingly larger share of the automotive market, what can finishers expect in terms of demand for finishes? Mark Schario of Columbia Chemical shares his insights into the kinds of opportunities EVs present for finishers.

#asktheexpert

The Importance of Strike Solutions

Electroplating strikes are used to improve adhesion and create a foundation for subsequent layers when plating. In this helpful article, Adam Blakeley of MacDermid Enthone offers an insightful guide to understanding electroplating strikes.

Autonomous Heating System Features Built-In Safety Measures

Process Technology’s Tomtech heating system features remote monitoring, built-in safety features and autonomous operation.

#Industry40 #regulation

Vishnu Chemicals Expands to Americas

Vishnu Chemicals is launching their chromic acid range in the Americas which will benefit the wood preservation and electroplating industries.