Episode 17: 2022 Finishing Hall of Fame Inductee Tony Revier

Tony Revier of Uyemura International discusses his experiences in the industry, as well as his insights into what the future might hold for surface finishing.

#regulation

Electrolytic Rack Stripping Best Practices

J.R. Eyerly of Haviland Enterprises discusses the benefits of switching to an electrolytic strip from a nitric-based nickel strip for rack stripping, as well as best practices to ensure desired results.

#asktheexpert

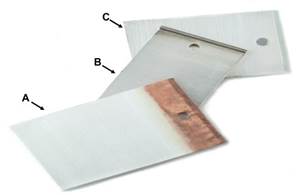

Know Your Tank Liner Options

Experiencing tank trouble? Curtis Goad of GOAD Company, supplier linings, plating tanks and critical containment, discusses tank lining options.

#asktheexpert

Technic Appoints Western Regional General Manager

Stephen LeClaire assumes the role of Technic’s Western Regional General Manager.

Los Alamos National Laboratory Unveils Renovated Finishing Facility

New, state-of-the-art finishing shop enables unique mission work.

Pioneer Achieves Medical Device Certification

Pioneer Metal Finishing’s South Bend, Indiana based Medical Center of Excellence facility has achieved ISO 13485 medical device certification.

#education

Diversity and Company Culture Define Top Shop

2022 Top Shop Hohman Plating puts an emphasis on quality, a wealth of services and company culture.

#management #topshops

Contaminants in a Bright Nickel Bath

Preventative maintenance for mitigating the accumulation of impurities.

An Interview with Jim Jones, DIFCO

Jim Jones, consultant and former vice president of DIFCO, discusses his experience in the surface finishing industry.

#surfin

A Process for Alkaline Non-cyanide Silver Plating for Direct Plating on Copper, Copper Alloys and Nickel Without a Silver Strike Bath

Traditionally, silver is electroplated in toxic, cyanide-based chemistry. Due to cyanide’s extreme hazard to human health and environments, developing non-cyanide silver chemistry is essential for the silver electroplating industry. Discussed here is an aqueous, alkaline non-cyanide silver plating technology, which can be directly plated over nickel as well as copper and its alloys. The silver deposits have perfect white color and better anti-tarnishing properties than other non-cyanide silver processes. The silver is plated entirely from the dissolving silver anode and the bath is very stable, and maintains a stable pH level both during plating and idle time. This new non-cyanide silver technology will plate bright silver that is perfectly suitable for electronic, industrial and decorative applications.

.

#medical #nasf #surfin