EPA Releases Milestone Health Assessment for Hexavalent Chromium

The U.S. Environmental Protection Agency announced in recent days the release of its long-anticipated human health assessment for hexavalent chromium. The assessment is expected to drive tighter requirements and pressure for new restrictions, and the industry has major concerns with the agency’s science in early reviews of the draft. NASF plans to submit comments during the 60-day comment period, which ends on December 19, 2022.

#regulation

SurTec, Okuno Expand Cooperation to Europe

Surface treatment specialist SurTec announces cooperation with Okuno Chemical Industries Co. Ltd. in Europe.

How to Choose the Right Coating for Fasteners

Choosing the proper coating for fasteners can help with performance by improving durability and lifespan. In this helpful Ask the Expert article, Mark Schario of Columbia Chemical offers advice for choosing the right fastener coatings.

#asktheexpert #basics

Valve Finishes

Nickel and chrome plated brass plumbing valve bodies by Everbright Metal Finishers.

#photofinish

Corrosion Protection Via Selective Plating

Carbon and high strength steels are some of the most widely used metals today, and the corrosion of this type of material is a serious problem for a variety of industries. However, corrosion can largely be controlled with developments in various protective solutions. Sarah Medeiros, Corrosion Engineer at SIFCO ASC, discusses developments in R&D to help slow down the corrosion process.

#aerospace

Cleaning, Pretreatment to Meet Medical Specs ISO 13485 or FDA 21 CFR820

Maximilian Kessler from SurTec explains new practices for industrial parts cleaning, metal pretreatment and decorative electroplating in the medical device industry.

#asktheexpert #medical #basics

NASF Offers Online Industrial, Precious Metals Plating Course

NASF and its educational branch AESF are offering an online educational course for plating on industrial and precious metals.

#nasf #education

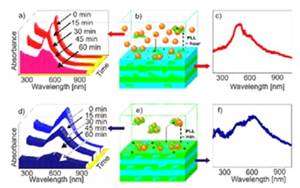

Nanostructure of the Anodic and Nanomaterials Nanoparticles in Polyelectrolyte Multilayer-by-Layer (LbL) Films

Microstructure and elemental characterizations have indicated that the finish of a coating with a Layer-by-Layer (LbL) film results in a closely multilayered coating with a smoother surface. In this paper, the principles of assembly are discussed together with the properties of nanoparticles and LbL polymeric assembly essential in building hybrid coatings.

#nasf #additive-manufacturing #surfin

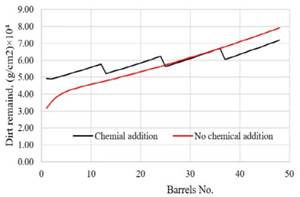

Smart Modeling and Simulation of Electroplating Systems for Real-Time Monitoring of Chemical, Water and Energy Consumption (NASF Summer Research Grant)

An AESF Foundation summer research grant provided an excellent opportunity for a PhD student to learn how to use chemical engineering fundamentals to scientifically characterize an electroplating process through integrated dynamic modeling and simulation, and how to develop digital twin (DT)-based virtual plant that can be of any process configuration. This is a critical step for the investigation of new technology development for smart and sustainable manufacturing in the surface finishing industry.

#sustainability #nasf #measurement-testing

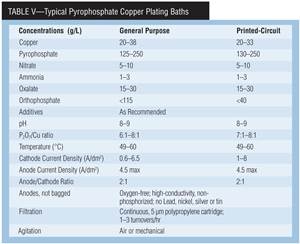

Choosing and Troubleshooting Copper Electroplating Processes

Learn more on this inexpensive and highly efficient process.

#basics