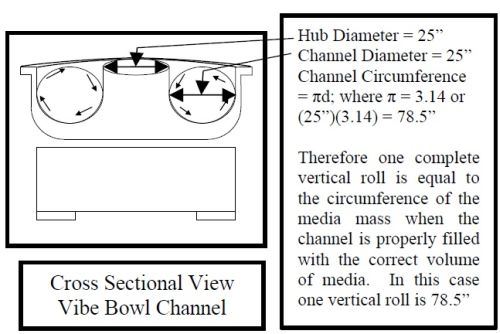

Calculating Applied Media Force During Vibratory Finishing

What appear to be identically set-up vibratory bowls will finish identical loads of parts in varying time cycles. This paper offers a new technique to better predict what the operator will produce, by measuring the force applied to the parts. It is the efficiency of that force which controls the efficiency and speed of the refinement cycle.

William Nebiolo

, REM Chemicals

Material Database Enables Coating Thickness Measurement Without Calibration

The database from Coatmaster AG has calibrations of over 400 different RAL colors.

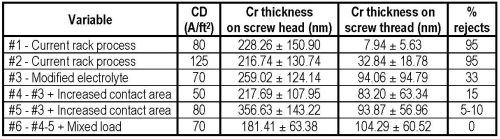

Electro-codeposition of MCrAlY Coatings for Advanced Gas Turbine Applications - 8th Quarterly Research Report

This NASF-AESF Foundation research project report covers the eighth quarter of project work (October-December 2019) on AESF Foundation Research at Tennessee Tech. The objective of the work is to study and optimize the MCrAlY electro-codeposition process to improve the coating oxidation/corrosion performance. In this quarter, the effects of particle density and shape on codeposition were studied. The results show that the shape of the particles plays an important role.

Correlation Between Electrochemical Behavior and Neutral Salt Fog Corrosion on TCP Coated AA2024

Differences in open circuit potential, electrochemical impedance spectroscopy and Tafel analysis were observed and quantified between the best- and worst-performing processes.

Best Plating Practices for the Application of Brush Plated Zinc-Nickel

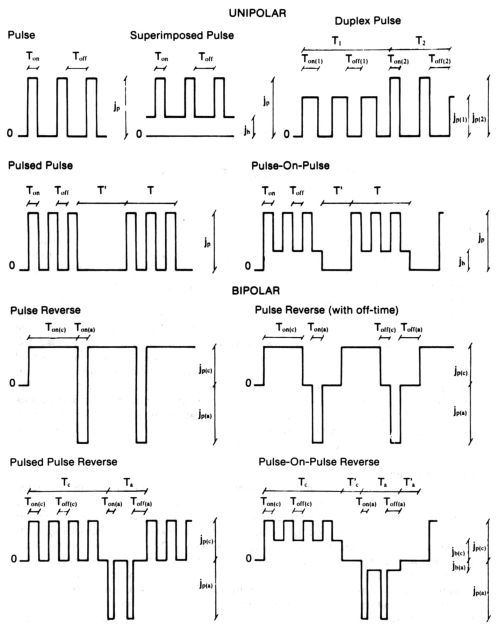

Brush plating is an industrial electroplating process designed for demanding OEM and repair applications, without the use of an immersion tank. This presentation demonstrates the best practices for brush plating zinc-nickel to meet the ASTM standards of hydrogen embrittlement and corrosion protection. From preparatory steps to the application of a trivalent chromium conversion coating, the proper plating techniques needed to meet the customers’ demanding requirements are discussed.

Nanostructure of Porous Anodic Aluminum Oxide: Advances in Surface Engineering

Porous alumina membranes of anodic aluminum oxide (AAO) are widely used for the fabrication of various nanostructures and nanodevices. Over the last decade, nanowires, nanotubes and nanodot arrays, have been fabricated by the deposition of various metals, semiconductors, oxides and polymers inside the pores of AAO membranes. These structures are produced by changing the anodization conditions, during electrochemically self -ordering of AAO. One can obtain amorphous barrier-type oxides, crystalline barrier-type oxides or amorphous nanoporous oxides, but fabricating binary nanostructures is challenging. Here, we review methods to achieve diverse binary nanostructure arrays, including material, dimension and morphology.

Electrochemical Destruction of Perfluorooctanesulfonate in Electroplating Wastewaters - 1st & 2nd Quarterly Report

This is the first report on a new NASF-AESF Foundation research project dealing with PFAS - a critical issue for the surface finishing industry. The project will study an electrochemical, destructive treatment strategy for the remediation of relevant PFASs in electroplating wastewater. The overall objective is to utilize a cost-effective reactive electrochemical membrane (REM) for the removal of PFAS from synthetic electroplating wastewater.