Who's Ready to Get On the Road Again?

Despite challenges, the surface finishing industry ramps up for a return to sorely missed in-person business and networking opportunities.

#surfin #editorial #regulation

Registration for SUR/FIN 2021 has opened and the steering committee is ramping up for the show in November in Detroit.

If you can say anything about the past year, it’s that it hasn’t been boring. Each month I start thinking about a theme for my column to tie together the latest issue of Products Finishing. Every time I start worrying that I’m going to run out of things to say, a quick look at my inbox and to-do list yields the more difficult task of deciding which topic demands the most focus. There is so much going on in the industry at the moment from raw materials shortages and supply chain disruptions to accelerated timelines for imposing new regulations on metal finishers.

PF has recently been reporting on the new hexavalent chrome phase-out deadlines proposed by the California Air Resources Board (CARB) and what those changes could mean for metal finishers in the state, as well as for the industry at large. Our On the Line podcast interviews delve into some different points of view about the issue from the voices of those in the midst of the conversation:

Featured Content

- Check out an interview with Bryan Leiker, executive director of the Metal Finishers Assn. of California (MFACA) and manager of K&L Anodizing in Burbank and Justin Guzman, president of the Metal Finishing Association of Southern California (MFASC) and president of Aircraft X-Ray Laboratories in Los Angeles. The pair discuss what these aggressive deadlines might mean for California-based finishers and what it could mean for the rest of the country if the industry moves out of state. Listen here: short.pfonline.com/XxoGObuu

- And for another point of view, check out a conversation with Mark Schario, executive vice president with Columbia Chemical, to hear about the latest innovations in trivalent chromium plating technology. Listen here: short.gardnerweb.com/hexpart1

In this issue of PF, as coverage of the conversation revolving around hex chrome regulations continues, Shane Moore of Pavco offers insights into plating operations contemplating switching from decorative hexavalent chromium to trivalent (see page 56).

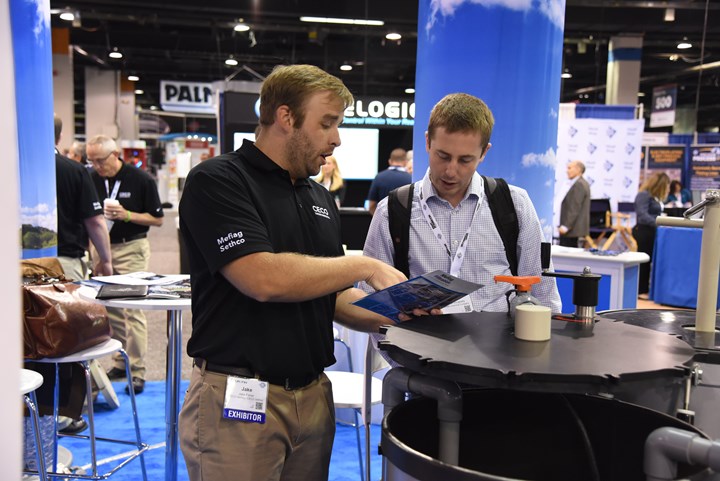

At the same time, in the face of some definite challenges, the surface finishing industry is ramping up efforts for a return to sorely missed in-person business and networking opportunities. I recently booked my first plane ticket since the COVID pandemic quarantine began last year. After a year of trade show cancellations, it feels strange to be finally gearing up for some in-person events. The first show I plan to attend will be Powder Coating Week in July in Orlando and things are ramping up from there. The Precision Machining Technology Show (PMTS) is in August and features a Parts Cleaning Conference. This month PF offers a preview of September’s FABTECH, which is poised to reunite the manufacturing and finishing industries after the past year’s hiatus (see page 36). In October, Products Finishing is teaming up with our sister publications Modern Machine Shop, CompositesWorld and Plastics Technology for the co-located Top Shops Expo, celebrating shops that participate in the Top Shops benchmarking program and offering programming and networking opportunities aimed at fostering innovation and collaboration (see page 11). Then, in November, the finishing community will have the opportunity to come together at SUR/FIN.

A return to these events will be a balm for an industry that has seen its fair share of challenges during the pandemic. Nevertheless, finishers have persevered through a tough year as a community. As we reunite through in-person events there’s no doubt that sharing the lessons we’ve learned and continue to learn will make the industry stronger as a whole.

RELATED CONTENT

-

Direct Copper Metallization of Aluminum: Elimination of Zincate

This article discusses the development of a new copper plating bath that can deposit high ductility copper metal directly on a wide range of aluminum alloy substrates. The process is particularly important for general metal finishing companies looking to plate aluminum parts for aerospace industry.

-

A Process for Alkaline Non-cyanide Silver Plating for Direct Plating on Copper, Copper Alloys and Nickel Without a Silver Strike Bath

Traditionally, silver is electroplated in toxic, cyanide-based chemistry. Due to cyanide’s extreme hazard to human health and environments, developing non-cyanide silver chemistry is essential for the silver electroplating industry. Discussed here is an aqueous, alkaline non-cyanide silver plating technology, which can be directly plated over nickel as well as copper and its alloys. The silver deposits have perfect white color and better anti-tarnishing properties than other non-cyanide silver processes. The silver is plated entirely from the dissolving silver anode and the bath is very stable, and maintains a stable pH level both during plating and idle time. This new non-cyanide silver technology will plate bright silver that is perfectly suitable for electronic, industrial and decorative applications. .

-

Defects in Hard Chromium Deposits Part I: Causes and Cures

The causes of and remedies for defects in hard chromium deposits are explored in the first of this two-part P&SF article from 1984. Photomicrographs and SEM (scanning electron microscope) photographs will illustrate that most defects in various hard chromium deposits arise from defects in the basis metal. These defects may be in the original metal surface or may be caused by preplate finishing. Homogeneous hard chromium deposits can be produced only by eliminating these defects. Practical suggestions and procedures will be given.