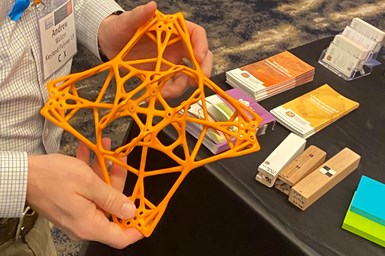

Andrew Walton, Keyland Polymer, shows an additively manufactured part coated with Keyland’s UV powder.

Photo Credit: Products Finishing

Often when I’m working on an issue of Products Finishing, something in the month’s travels or interactions with our friends in the industry will spark the topic of my editorial column. As we worked to put the final touches on our March issue, I had the pleasure of attending the Powder Coating Institute’s Powder Coating Week 2023. In what would seem to be a bit of serendipity, our March issue ended up compiling several powder coating-centric stories. We didn’t really plan it that way — this issue of the magazine was planned with a focus on recreational markets. I had it in my mind that we hadn’t touched on finishing applications for the marine industry in a minute and the perfect story had fallen in my lap during a recent excursion to check out some powder coating facilities in northern Indiana. As a result, an amazing story of collaboration and innovation between boating manufacturer Smoker Craft and Winona Powder Coating, as well as material and chemistry suppliers, kicked off what ended up being a rather powder coating-heavy issue of PF.

In addition to the boating application cover story, we also talked with construction products provider Global Building Products about its use of UV powder coating to resolve quality issues that it was experiencing while protecting heat-sensitive materials used in door and window systems. Inspired by a recent PF webinar, we turned to Steve Houston of Vitracoat America to learn about 12 often overlooked powder coating procedures that can help powder coaters evaluate quality, streamline operations and ultimately improve profitability. This month’s powder coating Ask the Expert Clinic features powder gun advice from Jeff Hale of Gema as he helps demystify which manual setting — voltage or current — is better to adjust depending on the application.

As I geared up for my annual trip to Powder Coating Week, it dawned on me that March was shaping up to be sort of an “Unofficial Powder Coating Issue” for PF. And what better time to dig into powder coating (not to mention some pretty perfect weather in Orlando)? As I talked with conference attendees, visited exhibitors and reflected on some of the stories PF has worked to curate for this issue of our magazine, I found myself increasingly excited about the place powder coating holds in the overarching surface finishing industry.

Advances in the ways powder coating is being used abound. The growing number of applications include use in EV battery systems as powder coating can aid battery performance by offering protection against corrosion and insulation from electrical current. UV cure powders are seeing increased use for protecting heat-sensitive materials, including those used in 3D printed parts.

In addition, the ways that powder coating offers environmentally friendly and sustainable options for coatings only continues to grow. Already lauded as a low-VOC (volatile organic compounds) and reclaimable material, there are increasing options for recycling reclaimed powder. There are also powders that are being created from recycled materials such as rPET (recycled polyethylene terephthalate) — better known as recycled plastic water bottles. (We’ll dig a bit more into powder recycling in the forthcoming April issue of PF as part of an environmental focus.)

Powder Coating Week was a fantastic celebration of what a vibrant industry powder coating is with plenty of innovation and growing opportunities.

Kudos to the Entire Finishing Industry

Speaking of celebrating — March is also the perfect time to reflect upon the entirety of the finishing industry. National Surface Finishing Day (NSFD) was celebrated on March 1 — the overarching goal of NSFD is to help bring increased awareness to the vital roles coating and plating operations play in their communities. Facilities are encouraged to host events and work with local media to build awareness about the contributions made by the surface finishing industry. Every NSFD, I’m inspired by the number of celebrations I see and am reminded of the sheer amount of things that require some sort of coating for corrosion protection and/or performance. When you consider the constant pressures of changing regulatory policies and environmental and sustainability concerns, then you begin to realize the sheer amount of work and innovation that goes into constantly improving the surface finishes that impact our lives every single day — a cause to celebrate indeed.

Related Content

SPS Atlanta 2025 Addresses Manufacturing Challenges With Automation-Focused Solutions, Dynamic Education Programs

Taking place September 16-18, 2025, at the Georgia World Congress Center, the U.S. debut of Smart Production Solutions (SPS Atlanta) offers a focused platform to drive automation forward and reinforce American industrial strength.

Read MorePowder Coating Week 2024 Offers Education and Networking

On March 11-13, 2024, this event for powder coaters will combine training, presentations, technical sessions, tabletop exhibits, roundtable discussions, expert panels and social activities.

Read MoreSUR/FIN 2025 Invites Finishers to Learn, Discover and Connect

NASF’s SUR/FIN surface finishing industry conference and trade show will take place June 3-5, 2025 in Rosemont, Illinois.

Read MoreEducation Initiatives Move the Finishing Industry Forward

Some of the usual suspects are working hard in the industry to bring continuing education to the forefront. Learn about some new opportunities for training as well as updates to tried-and-true programs.

Read MoreRead Next

Calculating the Cost of Powder Coating

How can you calculate the cost of powder coating a component if you only know its surface area? Powder coating expert Rodger Talbert has the answer.

Read MoreHow to Build a Powder Coating Brand

Maui Powder Works, a 2022 Products Finishing Top Shop, shares the story behind how it grew from an island job shop to a recognized voice in the finishing community.

Read MoreThe Powder Coating Process

Powder coating is one of the most durable finishes that can be applied to industrial manufactured products, and offers excellent corrosion protection and is very safe because of its lack of volatile organic compounds. To understand the powder coating process you should start with the fundamentals.

Read More